Top 2025 Rotary Screw Pump Innovations: What You Need to Know

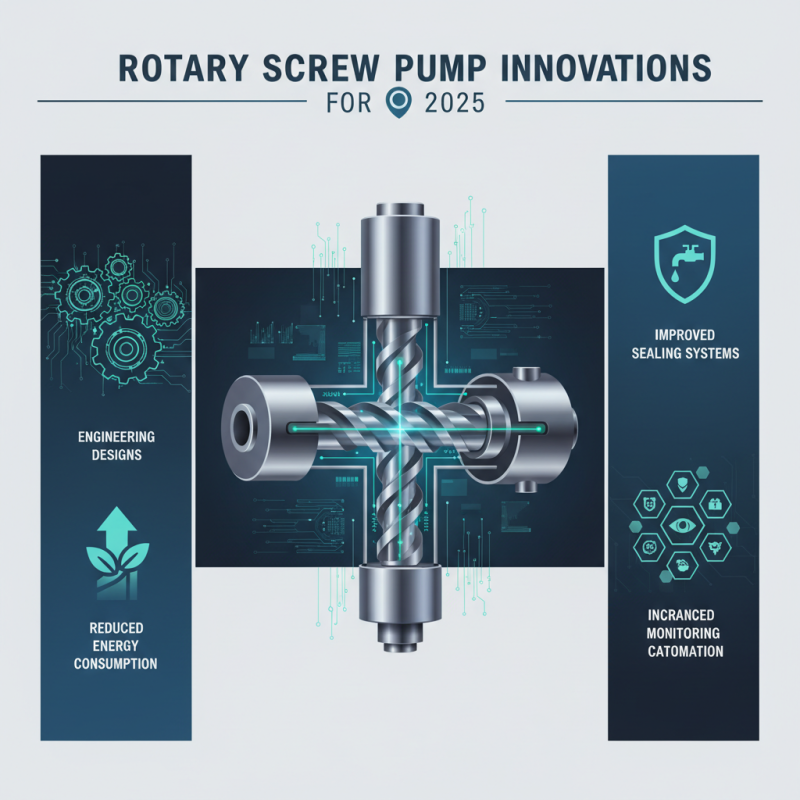

The rotary screw pump has long been a cornerstone of various industrial applications, known for its efficiency and reliability in moving fluids. As we look toward 2025, the evolution of rotary screw pump technology promises to bring significant innovations aimed at enhancing performance, reducing energy consumption, and providing greater versatility for a range of operational environments. These advancements stem from a combination of improved engineering designs and the integration of smart technologies, which are set to redefine how these pumps operate and interact within larger systems.

Understanding the upcoming innovations in rotary screw pumps is essential for industry professionals seeking to optimize their processes and maintain a competitive edge. With features such as increased automation, improved sealing systems, and advanced monitoring capabilities, the next generation of rotary screw pumps will not only enhance operational efficiency but also help to lower maintenance costs and extend service life. As we delve into the key trends and developments in this field, it becomes clear that staying informed about these advancements is crucial for maximizing performance and sustaining operational success in any fluid handling application.

Current Trends in Rotary Screw Pump Technology for 2025

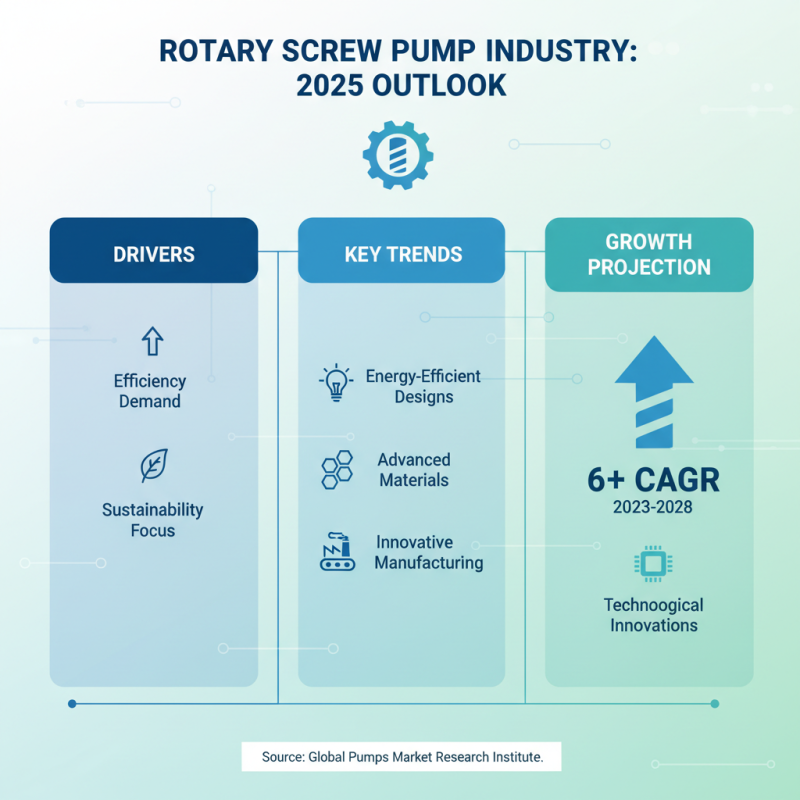

As we look toward 2025, the rotary screw pump industry is poised for significant advancements driven by the need for efficiency and sustainability. Current trends indicate a growing emphasis on energy-efficient designs that leverage advanced materials and innovative manufacturing processes. According to a report from the Global Pumps Market Research Institute, the rotary screw pump segment is expected to expand at a CAGR of over 6% from 2023 to 2028, largely due to these technological innovations.

One of the standout trends is the integration of smart technology within rotary screw pumps. Implementing IoT (Internet of Things) capabilities allows for real-time monitoring and predictive maintenance, reducing downtime and extending equipment life. A recent survey indicates that 70% of industry players recognize the importance of smart upgrades, highlighting a shift towards automated systems that optimize operational efficiency. Moreover, advancements in simulation software are enabling more precise design iterations, which can significantly improve performance and energy consumption metrics by as much as 15% over traditional methods.

Additionally, the focus on eco-friendly solutions is becoming more pronounced. The move towards using bio-based lubricants and recyclable materials in pump construction showcases the commitment of the industry to reducing environmental impacts. Reports project that companies adopting sustainable practices could reduce operational costs by up to 20%, showcasing the economic benefits alongside environmental responsibility. As these trends converge, the rotary screw pump technology landscape is set to evolve, meeting the demands of a more environmentally-conscious market.

Key Innovations Transforming Rotary Screw Pump Efficiency

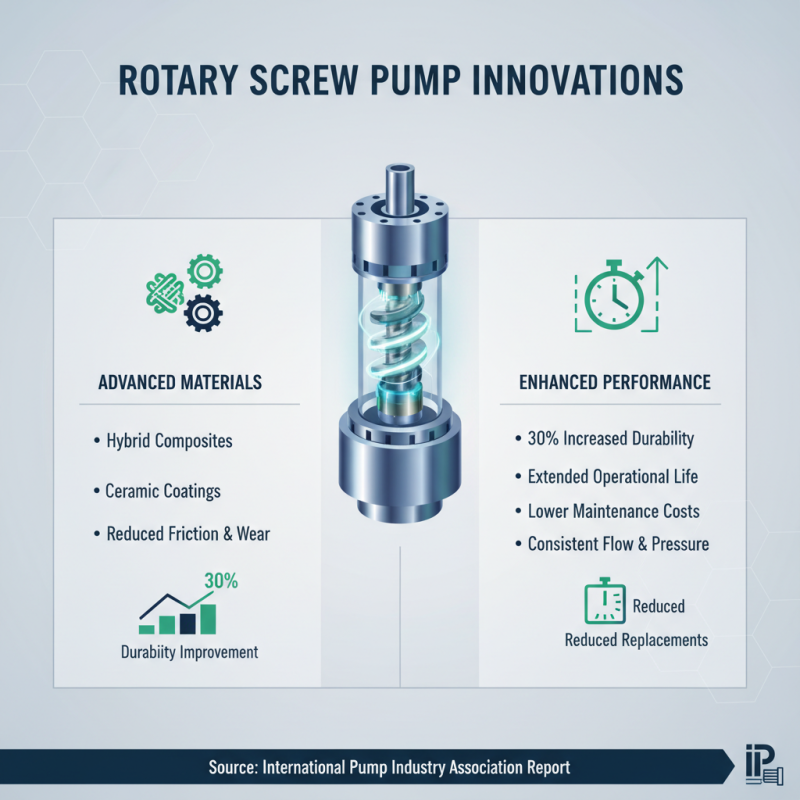

The rotary screw pump sector is undergoing significant transformations aimed at enhancing efficiency and performance. Recent innovations focus on advanced materials and coatings that reduce wear and tear in the pumps, leading to prolonged operational life and decreased maintenance costs. According to a report by the International Pump Industry Association, the use of hybrid materials can improve the durability of rotors by up to 30%, significantly lowering the frequency of replacements and ensuring consistent performance.

Moreover, the integration of smart technology and IoT solutions has revolutionized how rotary screw pumps operate and are monitored. Real-time sensor data enables predictive maintenance, allowing operators to address potential issues before they escalate into costly failures. As highlighted in a recent market analysis, companies that have implemented these smart technologies have experienced a reduction in downtime by approximately 25%, translating to substantial cost savings and improved productivity.

Innovation in rotary screw pump designs, such as optimized rotor profiles and enhanced sealing mechanisms, further contributes to energy efficiency. Enhanced designs can increase volumetric efficiency by as much as 20%, which is crucial in industries with stringent energy usage regulations. Transitioning to these advanced pumps not only meets industry demands for sustainability but also positions companies to better manage their operational expenses as energy costs continue to rise.

Environmental Impact and Sustainability in Rotary Screw Pumps

The environmental impact of rotary screw pumps has gained significant attention as industries increasingly prioritize sustainability. According to a report by the International Energy Agency, pumps account for approximately 20% of global electricity consumption in industrial settings, highlighting the importance of energy-efficient designs. Recent innovations in rotary screw pump technology focus on reducing energy usage and minimizing emissions, ultimately promoting sustainable practices. With advancements in materials and manufacturing processes, modern pumps are able to operate at higher efficiencies, reducing their carbon footprint and overall environmental impact.

Tips for selecting eco-friendly rotary screw pumps include looking for units with high energy efficiency ratings and those designed for lower noise levels. Additionally, consider pumps with features that allow for easier maintenance, as proper upkeep can significantly extend the life of the equipment, thereby reducing waste. By opting for these innovations, businesses can not only enhance their operational efficiency but also contribute to broader environmental goals.

As industries move toward sustainable solutions, the integration of smart technology in rotary screw pumps is becoming vital. IoT-enabled pumps can monitor performance in real-time, optimizing energy consumption and reducing resource wastage. Recent studies point to a potential 30% decrease in energy costs with the adoption of such technologies, showcasing the dual benefits of economic savings and environmental responsibility. Embracing these innovations is crucial for meeting both regulatory requirements and consumer expectations in a rapidly evolving market.

Top 2025 Rotary Screw Pump Innovations: Environmental Impact and Sustainability

| Innovation | Environmental Benefit | Energy Efficiency (%) | Maintenance Interval (Months) | Recyclable Materials (%) |

|---|---|---|---|---|

| Advanced Sealing Technology | Reduced fluid leakage and emissions | 20 | 12 | 80 |

| Smart Control Systems | Optimized performance and reduced waste | 30 | 24 | 70 |

| Variable Speed Drives | Lower energy consumption during operation | 25 | 18 | 75 |

| Eco-Friendly Lubricants | Reduced toxicity and environmental impact | N/A | 12 | 100 |

| Modular Design | Ease of repair and upgrade | 15 | 30 | 85 |

Future Applications of Rotary Screw Pumps Across Industries

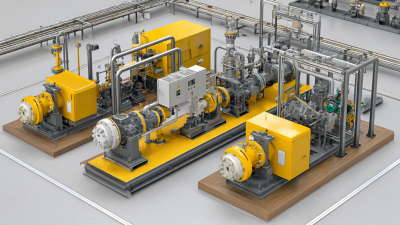

The future applications of rotary screw pumps across industries are poised for significant evolution, driven by advancements in technology and increasing demand for efficiency. With the global rotary screw pump market projected to reach USD 6.5 billion by 2025, industries such as oil and gas, water and wastewater management, and chemical processing are gearing up to leverage these innovations. Enhanced designs that improve energy efficiency by up to 20% can lead to substantial cost savings, particularly in sectors where operational expenses are critical.

In the manufacturing sector, rotary screw pumps are increasingly being utilized for fluid transfer processes due to their reliability and low maintenance requirements. A recent report indicates that the integration of smart technology, like IoT sensors, is enabling real-time monitoring of pump performance, which can reduce downtime and optimize pump longevity. Furthermore, industries are also exploring the potential of rotary screw pumps in renewable energy applications, such as biofuel production, where their efficiency and adaptability can significantly enhance output.

The versatility of rotary screw pumps is also extending into the food and beverage industry, where they are finding applications in the handling of viscous liquids and slurries. According to a study by the Industrial Pump Market Association, the demand for hygienic pumping solutions has surged, compelling manufacturers to develop models that meet stringent sanitary standards. This trend not only highlights the pumps' adaptability but also emphasizes the importance of innovation in meeting the evolving needs of various industries poised for growth in the coming years.

Top 2025 Rotary Screw Pump Innovations

The chart above illustrates the innovation levels in various aspects of rotary screw pumps, showcasing the expected advancements by 2025. Efficiency and durability are highlighted as key focus areas in future developments.

Challenges Facing the Development of Modern Rotary Screw Pumps

The development of modern rotary screw pumps is encountering several significant challenges that engineers and manufacturers must address to enhance their performance and efficiency. One of the primary issues pertains to the materials used in the construction of these pumps. As the demand for higher durability and corrosion resistance increases, finding the right materials that can withstand various harsh environments remains a top priority. This requires ongoing research and development to identify composites that not only maintain performance under extreme conditions but also reduce the overall weight and cost of the pumps.

Another challenge is the integration of advanced technologies. Modern rotary screw pumps are expected to operate with greater versatility and intelligence, incorporating features such as real-time monitoring and automation. However, integrating these high-tech solutions can be complex, often leading to compatibility issues with existing systems. Additionally, there is the challenge of ensuring that these innovations do not compromise the reliability and simplicity that users expect from rotary screw pumps. Overcoming these obstacles will be crucial for advancing product design and meeting the evolving needs of various industries, ultimately ensuring that rotary screw pumps remain a vital component of fluid transfer systems.

Related Posts

-

10 Best Rotary Screw Pumps for Efficient Fluid Transfer in 2023

-

2025 How to Choose the Right Positive Displacement Water Pump for Your Needs

-

Top 10 Pumps for Oil to Maximize Efficiency and Performance

-

2025 Top 10 Displacement Pumps: Market Trends & Key Performance Insights

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

-

Why Choose a Screw Vacuum Pump for Your Industrial Applications