2025 Top 10 Displacement Pumps: Market Trends & Key Performance Insights

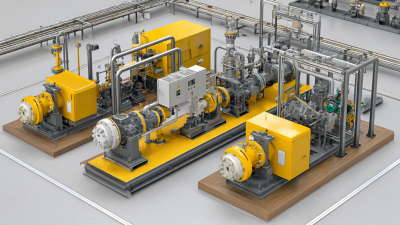

The displacement pumps market is undergoing significant transformation, driven by technological advancements and evolving industry demands. As we approach 2025, understanding the top displacement pumps becomes crucial for stakeholders aiming to stay competitive. According to the recent report by Grand View Research, the displacement pump market is projected to reach USD 12.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.8%. This growth is primarily attributed to the increasing demand in various end-user industries, including oil and gas, water treatment, and chemical processing.

Industry experts like Dr. Emily Carter, a renowned authority on fluid dynamics, emphasize the importance of innovation in this sector. She stated, "The efficiency and reliability of displacement pumps are pivotal in optimizing operational processes across diverse applications." Her insights highlight the need for manufacturers to focus on enhancing pump design and material quality to meet the rigorous demands of modern operations.

In this article, we explore the top 10 displacement pumps expected to lead the market in 2025, examining the latest trends and key performance insights. By delving into specifications and application areas, we aim to provide a comprehensive understanding of which displacement pumps will set benchmarks in efficiency and reliability in the coming years.

Top Industry Trends Influencing Displacement Pump Development in 2025

The displacement pump market is poised for significant growth in 2025, propelled by several key industry trends. According to a recent Market Research Future report, the global displacement pump market is projected to expand at a CAGR of 4.5% from 2023 to 2028, driven primarily by advancements in technology and increasing automation across various sectors. The demand for these pumps is being notably influenced by the oil and gas industry, which is expected to account for over 25% of the market share, as companies seek to enhance efficiency and reduce operational costs through innovative pumping solutions.

Another trend gaining momentum is the rising focus on sustainable and environmentally friendly practices. Research by the Global Industry Analysts indicates that manufacturers are increasingly adopting environmentally conscious designs, integrating sensors and smart technologies to improve energy efficiency. This shift not only aligns with global sustainability goals but also meets the growing consumer demand for greener products. Moreover, the development of IoT-enabled pumps is changing the landscape, allowing for real-time monitoring and predictive maintenance, which are essential for optimizing pump performance and reliability in critical applications.

Key Performance Metrics for Leading Displacement Pumps

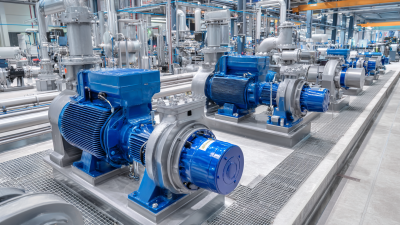

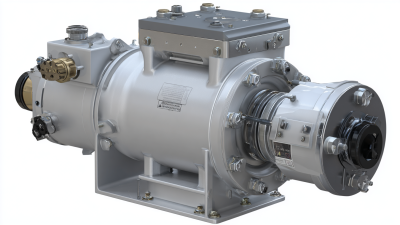

The performance of displacement pumps is critical for a variety of industrial applications, particularly in sectors such as oil and gas, water treatment, and chemical processing. Key performance metrics include flow rate, pressure capability, and efficiency. Flow rate, typically measured in gallons per minute or liters per second, serves as a primary indicator of a pump's capacity to move fluids. In 2025, leading displacement pumps are expected to showcase enhanced flow rates, driven by advancements in materials and design that reduce friction and increase overall effectiveness.

Another essential metric is pressure capability, which determines the pump's ability to handle demanding applications where high pressures are required. Manufacturers are innovating designs that can sustain higher pressures while maintaining reliability. Additionally, energy efficiency continues to be a significant factor, as businesses strive to reduce operational costs and comply with environmental regulations. The top displacement pumps in 2025 will likely integrate smart technologies to optimize performance, providing real-time data analytics to monitor efficiency levels, which ultimately improves decision-making in fluid management systems.

Innovative Technologies Shaping the Future of Displacement Pumps

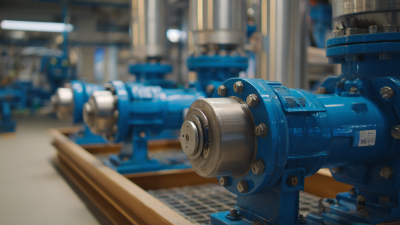

The future of displacement pumps is being significantly shaped by innovative technologies aimed at enhancing efficiency, reliability, and versatility. Advances in materials science have led to the development of lightweight yet durable components that withstand harsh environments, thereby extending the operational lifespan of pumps. Furthermore, intelligent automation is revolutionizing how displacement pumps are monitored and controlled, enabling real-time data analysis and predictive maintenance. This ensures optimal performance while minimizing downtime and operational costs, making these pumps more appealing across various industries.

Additionally, the integration of IoT (Internet of Things) capabilities has transformed displacement pumps into smart devices capable of communicating performance metrics and maintenance needs. This connectivity allows operators to optimize pump operation by continuously adjusting settings based on real-time data, enhancing energy efficiency and overall productivity. Moreover, the emergence of advanced sealing technologies reduces the risk of leaks and enhances the safety of fluid transport, particularly in sectors where hazardous materials are involved.

As these technological innovations continue to evolve, the displacement pump market is expected to expand, driven by increased demand for more efficient and sustainable pumping solutions.

Market Share Analysis of the Top Displacement Pump Manufacturers

The global displacement pumps market is experiencing significant growth, driven by increasing demand in the water and wastewater management sectors. According to market insights, the market size for water and wastewater pumps is projected to expand from $18.81 billion in 2025 to an impressive $30.61 billion by 2032. This surge indicates a compound annual growth rate (CAGR) that underscores the rising necessity for efficient fluid management solutions in various industrial applications.

A comprehensive analysis of market share reveals that leading manufacturers are focusing on innovations in pump technology to enhance performance and reliability. Positive displacement pumps—widely utilized for their ability to move fluids effectively against varying pressure conditions—are becoming increasingly favored among industries. Experts predict an uptick in the adoption of these pumps, given their efficiency and versatility across sectors such as oil and gas, chemicals, and municipal water services. As the market evolves, key players will likely continue to invest in research and development to capture a larger share in this competitive landscape.

2025 Top 10 Displacement Pumps: Market Trends & Key Performance Insights

| Rank | Pump Type | Flow Rate (GPM) | Pressure (PSI) | Efficiency (%) | Market Share (%) |

|---|---|---|---|---|---|

| 1 | Gear Pump | 45 | 1500 | 85 | 22 |

| 2 | Diaphragm Pump | 30 | 1200 | 90 | 18 |

| 3 | Screw Pump | 60 | 1700 | 80 | 15 |

| 4 | Piston Pump | 40 | 1300 | 88 | 12 |

| 5 | Vane Pump | 35 | 1100 | 82 | 10 |

| 6 | Lobe Pump | 50 | 1450 | 79 | 8 |

| 7 | Peristaltic Pump | 20 | 900 | 75 | 5 |

| 8 | Progressive Cavity Pump | 55 | 1600 | 86 | 6 |

| 9 | Multistage Pump | 25 | 800 | 78 | 4 |

| 10 | Spring Pump | 15 | 600 | 72 | 3 |

Consumer Preferences and Their Impact on Displacement Pump Design

The evolving consumer preferences are significantly shaping the design and functionality of displacement pumps. In today’s market, buyers are increasingly prioritizing efficiency and sustainability, prompting manufacturers to innovate their products. These pumps, essential for various applications across industries, must now meet stricter energy efficiency standards while minimizing environmental impact. As a result, companies are exploring advanced materials and technologies that not only enhance performance but also align with consumers' growing demand for eco-friendly solutions.

Moreover, the trend towards automation and smart technology integration is impacting displacement pump design. Consumers are looking for systems that offer real-time monitoring and control, allowing for improved operational efficiency and reduced downtime. This shift is driving the development of pumps that incorporate IoT capabilities, enabling predictive maintenance and streamlined processes. As customer expectations evolve, manufacturers must remain agile, adapting to these trends and refining their designs to meet the nuanced needs of the market while ensuring reliability and effectiveness.

2025 Top 10 Displacement Pumps: Market Trends

Related Posts

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

2025 Top 5 Lube Oil Systems: Enhance Engine Performance and Longevity

-

How to Choose the Right Type of Industrial Pump for Your Application

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

What is a High Pressure Positive Displacement Pump and How It Works in Industrial Applications