2026 Top Displacement Pumps Innovations and Trends to Watch?

As we look ahead to 2026, the world of displacement pumps is set to undergo significant evolution. These essential tools are crucial in various industries, from manufacturing to water management. Innovations in displacement pump technology will shape their efficiency and utility.

Emerging trends, such as smart automation and sustainable materials, are already being explored. For instance, improved energy efficiency in design could lead to lower operational costs. Moreover, innovations in digital monitoring will enhance reliability, but there are challenges to overcome.

While the future seems promising, it's essential to remain critical of potential pitfalls. Rapid advancements may lead to equipment that is hard to maintain. Companies must balance innovation with practicality. The journey towards realizing these advancements in displacement pumps is a complex one, filled with opportunities and uncertainties.

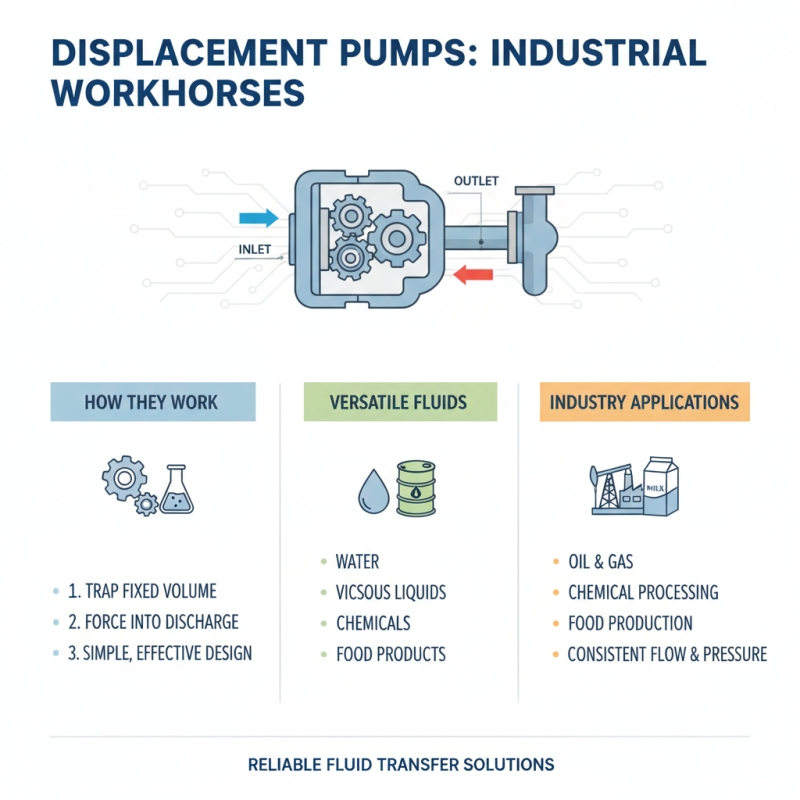

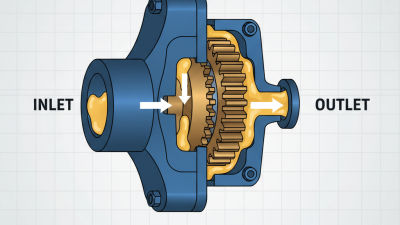

Overview of Displacement Pumps and Their Importance in Various Industries

Displacement pumps play a vital role across numerous industries. These pumps move fluids by trapping a fixed amount of liquid and forcing it into the discharge pipe. Their design is simple yet effective. This mechanism allows them to handle many different types of fluids, from water to viscous substances. In sectors like oil and gas, chemical processing, and food production, they ensure consistent flow and pressure.

However, not all displacement pumps are created equal. Some may struggle with efficiency or compatibility with certain fluids. This can lead to issues like cavitation or wear and tear. Understanding these shortcomings is essential for industries that rely on precise fluid management. Regular maintenance can mitigate some of these concerns, but operators must remain vigilant. Ensuring pumps operate in optimal conditions demands constant monitoring and adjustment. The next few years will see innovations aimed at enhancing pump reliability and efficiency.

Key Innovations in Displacement Pump Technology for 2026

Displacement pumps are evolving rapidly, guided by technology and market demands. In 2026, we expect notable innovations that enhance efficiency. According to a recent industry report, the global displacement pump market is projected to grow at a CAGR of 5.4%, reaching $14 billion by 2026. This growth is fueled by advancements in materials and design.

One key innovation is the integration of smart sensors into pump systems. These sensors monitor performance metrics in real-time. This ensures optimized operations, reducing energy consumption by up to 20%. Additionally, manufacturers are exploring biodegradable materials for pump construction. This shift addresses environmental concerns and meets regulatory demands.

Despite these advancements, challenges remain. For instance, the transition to smart technologies may incur high initial costs. Some industries may resist change due to outdated systems. Furthermore, not all regions have the infrastructure to support these innovations. Addressing these gaps is crucial for widespread adoption. Overall, the displacement pump industry is on the brink of significant transformation.

2026 Top Displacement Pumps Innovations and Trends

This chart illustrates the projected growth in various key innovations within displacement pump technology for the year 2026, highlighting the emphasis on energy efficiency, smart technologies, and materials development.

Emerging Trends in Efficiency and Sustainability for Displacement Pumps

The displacement pump industry is experiencing a notable shift towards efficiency and sustainability. Pump manufacturers are increasingly focusing on designs that reduce energy consumption. Innovations like advanced materials and optimized geometries lead to better performance. These changes can result in significant reductions in operational costs over time.

Moreover, sustainability is becoming a core value. Many companies are now using recyclable materials in their pumps. This choice addresses both environmental concerns and consumer demands. However, the transition to greener solutions isn’t always straightforward. Challenges remain in balancing cost and environmental impact. The industry must continue to innovate while ensuring that pumps remain economically viable for users.

The rise of digital technologies also plays a role in driving efficiency. Smart monitoring systems can detect potential failures early, preventing downtime. This proactive approach enhances productivity and minimizes waste. Yet, implementing such technologies can be complex. Organizations need to rethink their existing systems and invest in training for staff. As they adapt, the road to sustainability may not always be smooth.

2026 Top Displacement Pumps Innovations and Trends to Watch

| Innovation/Trend | Description | Impact on Efficiency | Sustainability Aspects |

|---|---|---|---|

| Smart Monitoring Systems | Integration of IoT for real-time performance tracking. | Improves operational efficiency by forecasting maintenance needs. | Reduces downtime and conserves resources through predictive analytics. |

| Advanced Materials | Use of lightweight and corrosion-resistant materials. | Enhances durability and reliability of pumps. | Lowers the environmental impact through reduced resource extraction. |

| Energy-Efficient Designs | Innovations in hydraulic design reduce energy consumption. | Maximizes output with minimal energy loss. | Supports global sustainability goals with lower carbon footprint. |

| Digital Twin Technology | Creates virtual replicas of physical systems for optimization. | Improves system efficiency and reduces operational costs. | Enables better resource management and sustainability planning. |

| Modular Pump Units | Flexible design for easy maintenance and upgrades. | Reduces downtime and simplifies replacement processes. | Extends product life cycle and reduces waste. |

Impact of Digitalization and Smart Technologies on Pump Operations

Digitalization and smart technologies are reshaping the landscape of pump operations. The integration of IoT devices enables real-time monitoring. This enhances efficiency and reduces downtime. Operators can track performance metrics from anywhere. Data analytics can predict potential failures, allowing for timely maintenance.

Tips: Invest in training staff on new digital tools. Ensure they understand the benefits and functionalities. Regularly update software to maximize performance.

AI-powered systems analyze vast amounts of data quickly. This can sometimes lead to over-reliance on technology. Human expertise is still crucial in decision-making. Balancing automation with human insight is vital. The flow of information should remain clear and accessible.

Tips: Establish clear communication channels. Foster collaboration between technical teams and operators. This helps in identifying issues faster and improves overall operation.

Future Challenges and Opportunities in the Displacement Pump Market

The displacement pump market is evolving rapidly. There are promising innovations on the horizon. However, challenges remain that need to be addressed.

One major challenge is the varying efficiency of pumps in different applications. Some pumps may not perform optimally in extreme conditions. Engineers must adapt designs to meet these diverse requirements. This could lead to more versatile pumps, capable of handling various fluids and environments.

Sustainability is another crucial area. Many industries are pressured to reduce their environmental impact. This could drive development in energy-efficient pump technologies. New materials and designs can help minimize waste and energy consumption. However, achieving sustainability while maintaining performance is a delicate balance. The path forward requires careful consideration.

Related Posts

-

2025 Top 10 Displacement Pumps: Market Trends & Key Performance Insights

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

-

Best Oil Lubrication Pumps for Efficient Machine Performance?

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency