2026 Top Displacement Pumps Innovations and Trends to Watch?

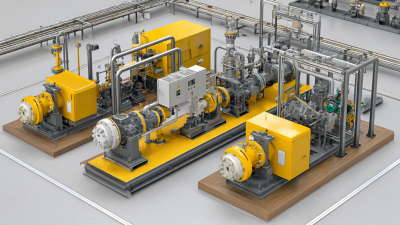

Displacement pumps are essential in various industries, from manufacturing to water treatment. The year 2026 promises exciting innovations for these pumps. New technologies aim to enhance efficiency and reliability.

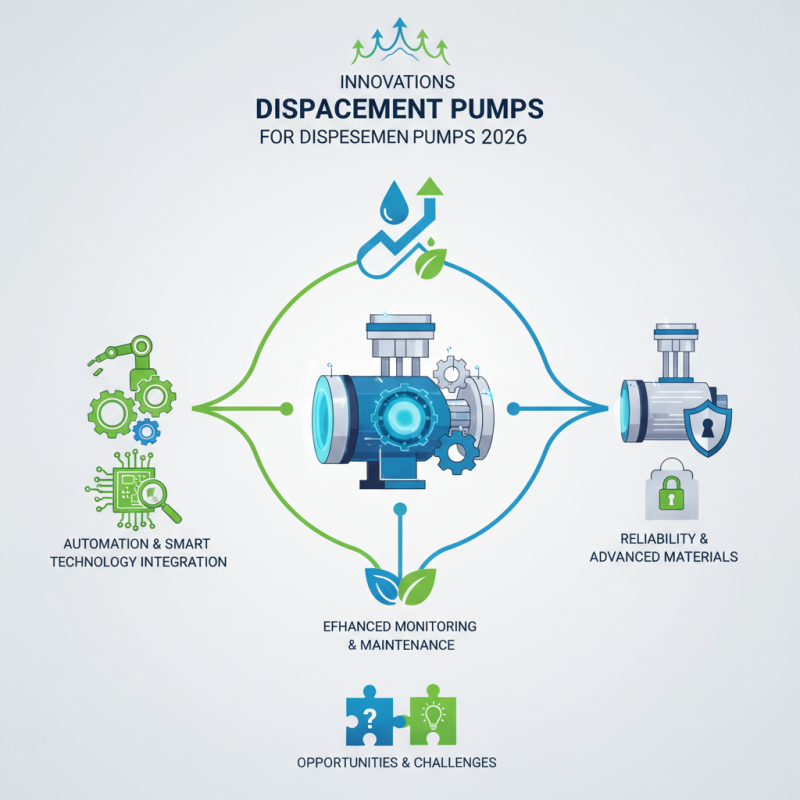

Recent trends highlight a shift toward automation and smart technology integration. These advancements could revolutionize how displacement pumps operate. Enhanced monitoring systems may lead to improved maintenance practices. However, these innovations also bring challenges that need careful consideration.

As the industry evolves, stakeholders must adapt to these changes. Balancing performance with sustainability is crucial. The future of displacement pumps lies in embracing innovation while addressing potential drawbacks. This dynamic landscape of displacement pumps showcases both opportunities and challenges.

Emerging Technologies in Displacement Pumps for 2026

The field of displacement pumps is experiencing exciting advancements as we approach 2026. Emerging technologies are reshaping how these pumps operate. One notable trend is the integration of IoT capabilities, allowing real-time monitoring. This ensures optimal performance and maintenance predictions. Additionally, advanced materials are being developed to boost durability and efficiency.

Another impactful innovation is the shift toward more energy-efficient designs. Pumps now feature better hydraulic designs that reduce power consumption. This is crucial as industries strive to lower their carbon footprints. Manufacturers are also exploring modular designs, which provide flexibility in applications. This can help in easier upgrades and maintenance, although it might complicate standardization.

Tips: Keep an eye on the growing emphasis on user-friendly interfaces. Design simplicity can enhance operator efficiency. Also, consider the potential of machine learning in predictive analytics for maintenance. It can save time and reduce costs. Be prepared for the mixed results these innovations may bring. Adaptation and continuous learning will be key.

Sustainability Trends Impacting Displacement Pump Design

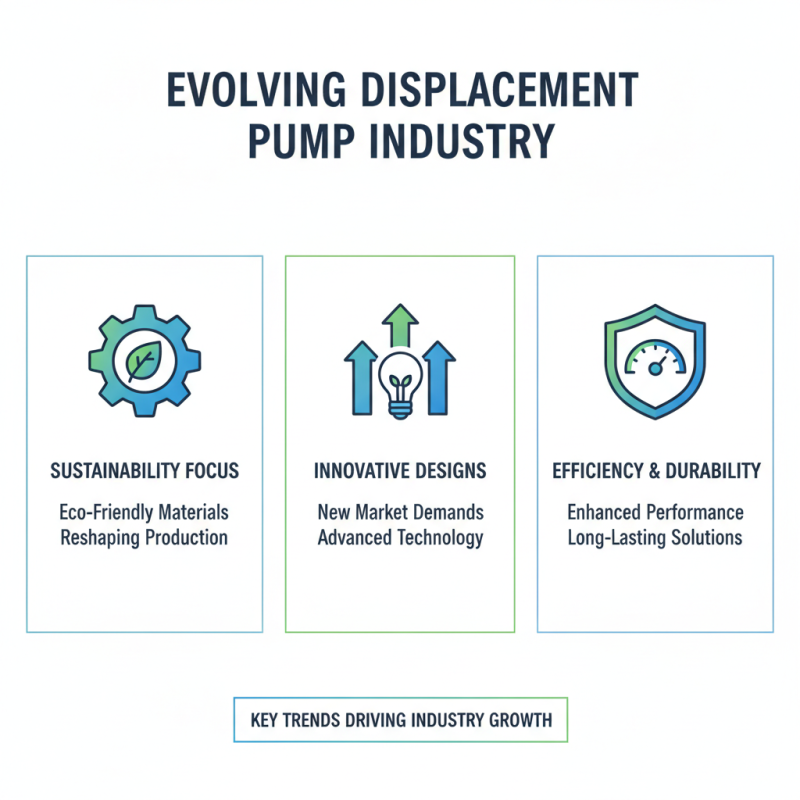

The displacement pump industry is seeing a meaningful shift toward sustainability. Manufacturers are integrating eco-friendly materials into their designs. This effort reduces environmental impact and enhances pump efficiency. The push for greener technologies reflects a broader commitment to sustainability.

Energy efficiency is increasingly crucial. Many designs now focus on minimizing energy consumption. This often includes innovative motor technologies. These improvements can lead to significant operational cost savings. However, some designs still struggle with balancing performance and eco-friendliness.

Recyclable materials are becoming more common. This trend promotes a circular economy. Yet, achieving durability while using sustainable materials remains challenging. Companies must consider the life cycle of their products. Continuous innovation is needed, but barriers still exist. The industry must embrace this change, even if it leads to growing pains.

2026 Top Displacement Pumps Innovations and Trends to Watch

| Innovation/Trend | Description | Impact on Design | Sustainability Aspect |

|---|---|---|---|

| Smart Pump Technology | Integration of IoT for monitoring and optimization. | Enhanced efficiency and real-time data tracking. | Reduced energy consumption and emissions. |

| Eco-Friendly Materials | Use of recyclable and biodegradable materials in pump construction. | Promotes a circular economy approach in manufacturing. | Minimization of environmental impact. |

| Energy Recovery Systems | Technologies for recovering and reusing energy in pump operations. | Increased overall efficiency of the pumping system. | Lowers the overall energy demand. |

| Modular Pump Designs | Flexible pump modules that can be customized for various applications. | Easier maintenance and scalability. | Longer lifespan reduces waste. |

| Advanced Seal Technologies | Innovations in sealing methods to prevent leaks and enhance reliability. | Improved durability of pumps. | Prevents contamination and wastage of fluids. |

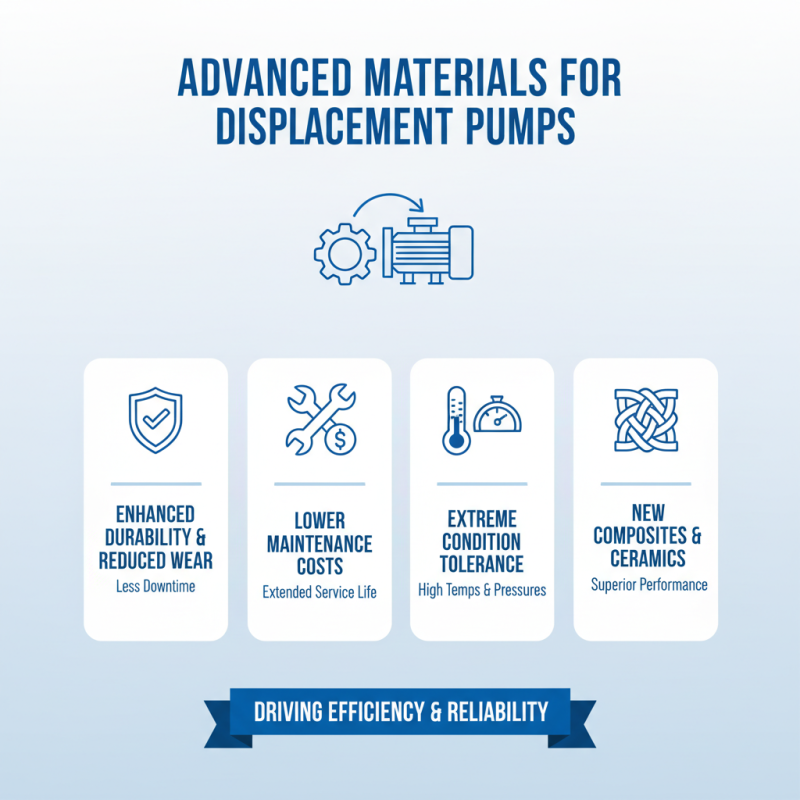

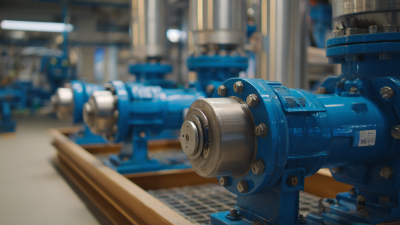

Advancements in Materials for Enhanced Pump Efficiency

In recent years, advancements in materials have driven the efficiency of displacement pumps. Enhanced materials can increase durability and reduce wear. This innovation leads to less downtime and lower maintenance costs. New composites can withstand harsh environments. They provide better performance in extreme temperatures and pressures.

Emphasizing lightweight designs has also helped improve efficiency. These materials enable faster operation and reduce energy consumption. However, balancing performance and cost remains a challenge. Not all materials deliver the same results, prompting ongoing research and testing.

**Tips:** Consider the environment where the pump will operate. Choosing the right material can make or break efficiency. Regular maintenance is key. Inspecting pumps can prevent issues before they escalate. Remember, small adjustments can lead to significant improvements.

Digital Integration: IoT and Automation in Displacement Pumps

Digital integration is transforming displacement pumps. The Internet of Things (IoT) allows for real-time monitoring. Sensors collect data on pressure, flow, and temperature. This data can trigger automatic adjustments. Pump performance improves, but challenges arise.

Automation enhances efficiency in setup and operation. Routine maintenance can be scheduled automatically. However, reliance on technology can introduce new vulnerabilities. Cybersecurity risks are a concern. Pumps may face unexpected failures due to software issues.

Embracing this technology requires careful consideration. Operators must continuously update their systems. Training staff on new tools is also essential. A balance between innovation and human oversight is crucial. As the industry evolves, so must the approach to technology integration.

Market Trends and Growth Projections for Displacement Pump Industry

The displacement pump industry is evolving quickly. Innovative designs are emerging to meet market demands. Sustainability is a major focus. Companies are investing heavily in eco-friendly materials. This trend could reshape production processes. Efficiency and durability are paramount. Innovations often prioritize these factors.

Market projections suggest steady growth. Analysts forecast a rise in energy-efficient models. Users want solutions that cut operational costs. Industry players must adapt to customer preferences. There is a visible shift towards smart technology. Integrating sensors and automation is key. Yet, challenges remain in implementation. Not every company is ready for these changes.

As new players enter the market, competition intensifies. Some established brands struggle to keep pace. They must rethink their strategies. There’s pressure to innovate quickly. However, rushing can lead to missteps. Reflecting on past projects can help. Learning from mistakes is essential for future success. Balancing innovation with reliability will define the next few years in this sector.

Related Posts

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

-

2025 Top 10 Displacement Pumps: Market Trends & Key Performance Insights

-

2026 Top Displacement Pumps Innovations and Trends to Watch?

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

What is a Crude Oil Pump and How Does It Work?

-

How to Choose the Right Lubrication Pump for Your Needs