Top Benefits of Positive Displacement Water Pumps and Their Uses

In the realm of fluid management and engineering, the importance of selecting the right pump cannot be overstated. Positive displacement water pumps have gained significant attention for their ability to provide consistent flow rates and handle a variety of applications efficiently. As noted by industry expert Dr. Emily Thompson, "The reliability and precision of positive displacement water pumps are crucial for industries that rely on accurate fluid movement." This sentiment underscores the growing reliance on such technology in sectors ranging from agriculture to manufacturing.

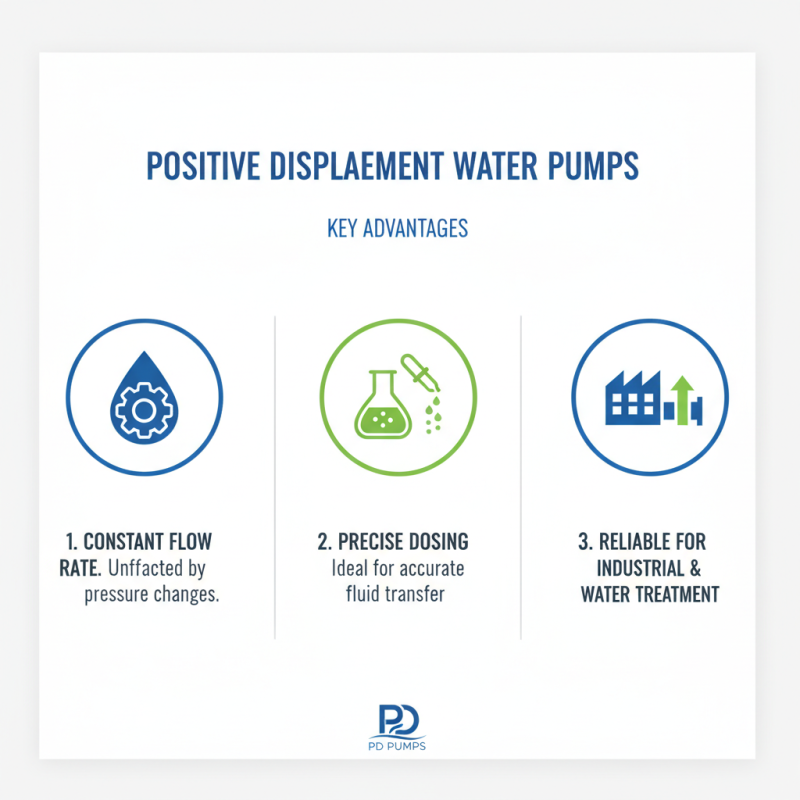

Understanding the benefits of positive displacement water pumps is essential for both engineers and end-users. These pumps are known for their unique operating principle, which enables them to trap a fixed amount of liquid and force it through the system, ensuring a steady flow regardless of system pressure changes. This characteristic makes them ideal for applications that require precise control over fluid delivery, such as chemical processing and wastewater management.

As industries evolve and the demand for reliable and efficient pumping solutions increases, it is clear that positive displacement water pumps will play a pivotal role. Their applications not only enhance operational effectiveness but also contribute to sustainability efforts by optimizing resource usage. Understanding their benefits and applications is not just a technical necessity—it is a strategic advantage in today's competitive landscape.

Benefits of Positive Displacement Water Pumps in Various Industries

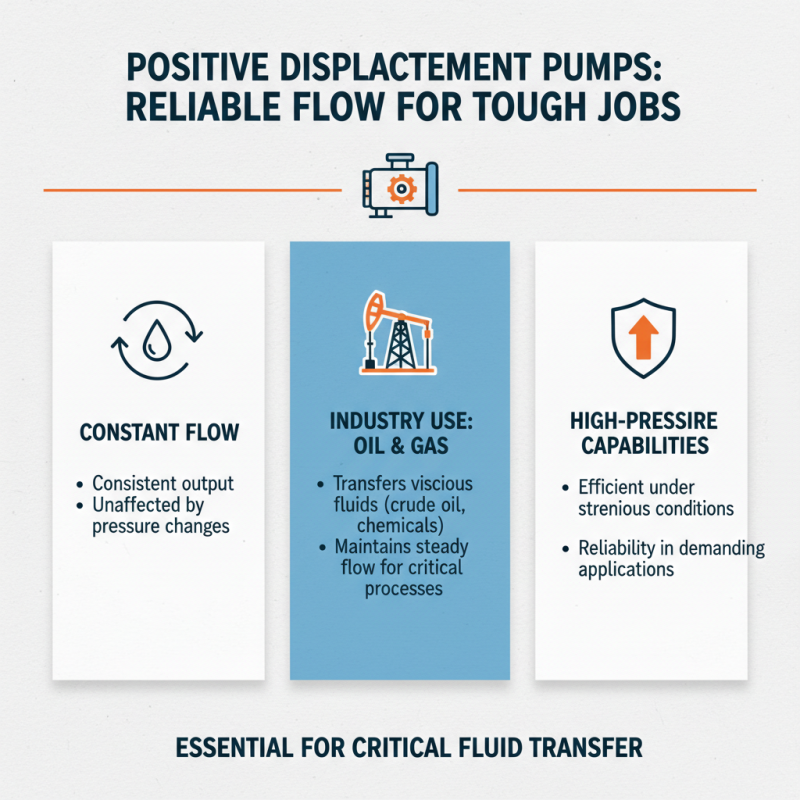

Positive displacement water pumps are widely used across various industries due to their unique ability to provide a consistent flow rate, regardless of changes in pressure. In the oil and gas sector, these pumps are essential for transferring viscous fluids, such as crude oil and thick chemicals, where maintaining a steady flow is critical. Their design ensures that they can handle high-pressure situations without compromising efficiency, making them a preferred choice for applications that require reliability under strenuous conditions.

In the food and beverage industry, positive displacement pumps play a vital role in ensuring hygienic and precise transfer of liquid ingredients. These pumps allow for the gentle handling of sensitive products, minimizing shear and ensuring that the quality of the product is preserved. Their ability to handle varying viscosities and provide accurate dosing makes them ideal for applications such as dairy processing, syrup production, and even in the brewing industry, where maintaining the integrity of flavors is paramount. Additionally, their ease of cleaning and maintenance helps organizations meet strict sanitary regulations.

Mechanism and Functionality of Positive Displacement Water Pumps

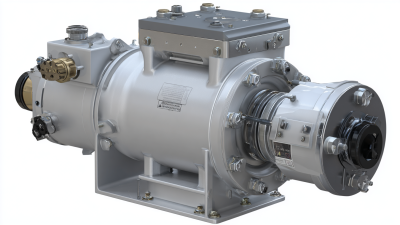

Positive displacement water pumps operate on a straightforward yet effective mechanism that distinguishes them from other types of pumps. These pumps work by trapping a fixed volume of fluid and then forcing it out of the discharge side, making them highly efficient for transferring water and other fluids. The process typically involves a series of gears, pistons, or diaphragms within a sealed chamber. When the chamber is filled, the mechanical action pushes the water out, ensuring a consistent flow that is not dependent on the pressure at the discharge side. This precise control over the volume of water being moved not only enhances performance but also enables these pumps to handle varying fluid viscosities without compromising efficiency.

The functionality of positive displacement water pumps is particularly advantageous in various applications where reliable and steady flow is crucial. From industrial machinery to agricultural irrigation systems, these pumps can maintain a uniform pressure and flow rate, making them ideal for tasks requiring accurate fluid delivery. Additionally, their ability to function effectively at different elevations and their self-priming features make them suitable for a plethora of environments, including construction sites and remote locations. Overall, the simplicity of their operation combined with their robust performance makes positive displacement water pumps an invaluable asset across multiple sectors.

Top Benefits of Positive Displacement Water Pumps

Common Applications of Positive Displacement Water Pumps

Positive displacement water pumps are widely utilized across various industries due to their effectiveness in moving fluids under pressure. One common application is in the oil and gas sector, where these pumps are used to transfer viscous fluids, ensuring consistent flow rates even when handling thick, heavy oils. Their ability to manage high-pressure scenarios makes them ideal for hydraulic fracturing, where precise control over fluid movement is crucial.

Another prominent application of positive displacement pumps is in wastewater treatment facilities. In these settings, they are employed to transfer sludge and other materials that may vary in viscosity. The pump's design allows it to handle solid-laden fluids without compromising performance, making it essential in maintaining operational efficiency within treatment processes. Additionally, these pumps are favored in food processing industries, where sanitary conditions are a priority. They facilitate the gentle handling of ingredients, ensuring minimal shear forces are exerted, thus preserving the integrity of the product during the transfer process.

Top Benefits of Positive Displacement Water Pumps and Their Uses - Common Applications of Positive Displacement Water Pumps

| Benefit/Feature | Description | Common Applications |

|---|---|---|

| High Efficiency | Positive displacement pumps provide consistent flow rates regardless of pressure, maximizing efficiency. | Water treatment plants, irrigation, and industrial processes. |

| Versatility | Can handle a variety of fluids, including viscous and non-Newtonian fluids. | Food processing, chemical transfer, and wastewater management. |

| Self-Priming | Can operate with a suction line that contains air without damaging the pump. | Construction sites and dewatering applications. |

| Durability | Built to withstand tough operating conditions and high pressures. | Mining operations, oil and gas extraction, and high-pressure cleaning. |

| Low Maintenance | Fewer moving parts compared to centrifugal pumps, leading to reduced maintenance needs. | Marine applications, hydraulic systems, and agricultural uses. |

Comparative Advantages Over Other Pump Types

Positive displacement water pumps offer several comparative advantages over other types of pumps, making them an excellent choice for various applications. One of the most significant benefits is their ability to maintain a consistent flow rate regardless of the pressure in the system. Unlike centrifugal pumps, which can lose capacity as pressure increases, positive displacement pumps provide a steady output, making them ideal for applications requiring precise dosing or constant flow. This consistency is especially valuable in industrial processes and water treatment systems.

Another advantage is their capability to handle viscous fluids and slurries more effectively than other pump types. Positive displacement pumps can efficiently move thicker substances that would obstruct centrifugal pumps, extending their usability across diverse industries such as food processing and chemical manufacturing. This versatility also reduces the risk of damage to the pump, ensuring longevity and lower maintenance costs.

**Tips:** When selecting a positive displacement pump, consider the specific fluid characteristics, including viscosity and potential solids content, to ensure compatibility. Additionally, always verify the pressure and temperature ranges to match the pump specifications and enhance its operational efficiency. Regular maintenance checks will also prolong the lifespan of your pump, ensuring optimal performance throughout its use.

Maintenance and Best Practices for Positive Displacement Water Pumps

Maintaining positive displacement water pumps is crucial for ensuring their efficiency and longevity. Regular inspections should be carried out to check for signs of wear, leaks, or blockages. It is particularly important to examine the seals and gaskets, as these components can wear down over time, leading to decreased performance and potential system failures. Additionally, operators should monitor the pump's operational parameters, such as pressure and flow rates, to ensure they are within the specified ranges. Any significant deviations should be addressed promptly to prevent further damage.

Best practices for maintaining positive displacement pumps include establishing a consistent maintenance schedule and keeping detailed records of all inspections and repairs. Lubrication is key, and it’s essential to use the recommended types and amounts of lubricant to prevent overheating and excessive wear. Cold weather operations require special attention to avoid fluid viscosity issues, which can impede performance. Finally, training personnel in proper operating procedures and maintenance techniques can significantly reduce the risk of malfunctions and enhance the overall reliability of the pump system.

Related Posts

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

2025 How to Choose the Right Positive Displacement Water Pump for Your Needs

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

Unlock the Power of High Pressure Screw Pumps: Applications and Benefits Explained

-

Top 5 Positive Displacement Pump Manufacturers You Should Know About

-

What is a High Pressure Positive Displacement Pump and How It Works in Industrial Applications