2026 Best Oil Lubrication Pump for Enhanced Machinery Performance?

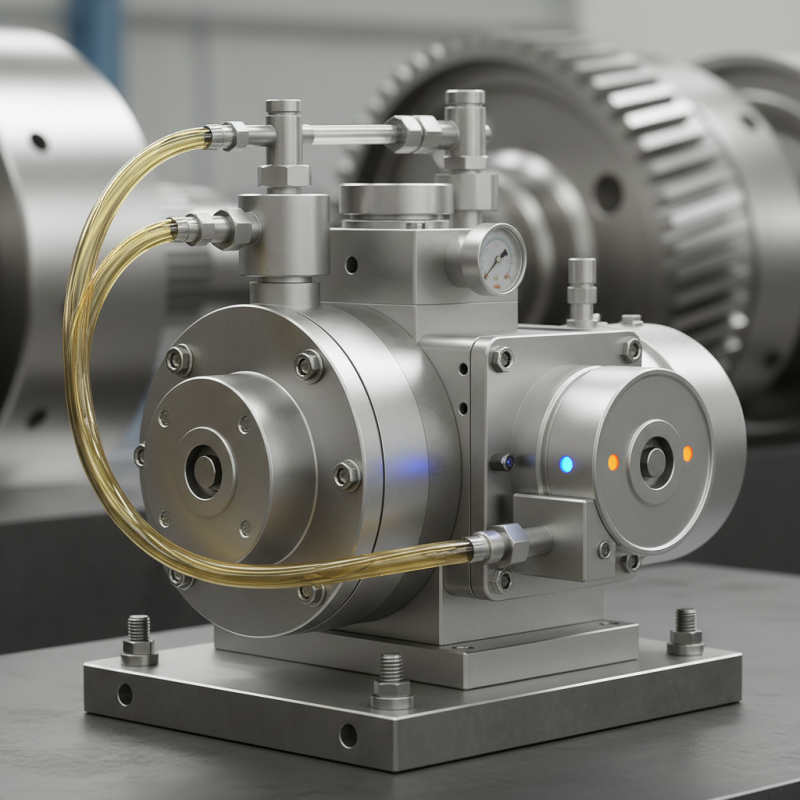

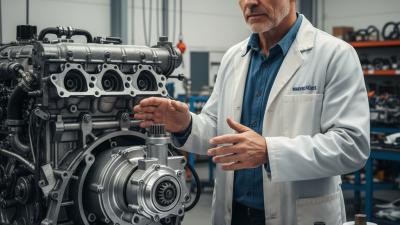

In the world of machinery, the efficiency of equipment greatly depends on effective lubrication. An oil lubrication pump plays a crucial role in this process. These pumps ensure that all moving parts receive adequate lubrication, reducing friction and wear. Enhanced machinery performance is often tied to the quality of the oil lubrication pump used.

Choosing the right oil lubrication pump can be daunting. Each type comes with its pros and cons. Some pumps excel in high-pressure environments, while others perform best in low-voltage situations. Reflecting on these differences is essential before making a decision.

Machinery operational demands may change, leading to unforeseen challenges. An excellent oil lubrication pump can help adapt and maintain performance. However, not all pumps are created equal; some may fail under pressure. Be mindful of the pump's specifications. The right choice can mean the difference between smooth operation and costly downtime.

2026 Trends in Oil Lubrication Pump Technology for Industrial Use

The oil lubrication pump sector is witnessing significant advances in 2026. Technology changes are improving performance for industrial applications. Smart sensors are now integral in monitoring oil condition. This enables timely maintenance and reduces downtime. Operators can access real-time data on lubrication levels.

Tips: Regularly check oil levels. This simple action can prevent pump failure. Keeping oil clean is crucial. Contaminants can cause wear and damage to machinery.

Many industries are exploring energy-efficient pumps. These pumps consume less power while maintaining performance. However, the trade-off is sometimes higher initial costs. It's essential to evaluate long-term savings versus upfront expenses. Remember, not every high-tech solution is suitable for all environments. Consider unique operational needs when selecting a pump.

Another emerging trend is modular pump designs. These designs allow easy upgrades as technology evolves. However, compatibility with existing systems can be a challenge. Take time to assess integration before making a change. A poorly matched pump could lead to inefficiencies.

Key Features to Consider for Optimal Machinery Performance Efficiency

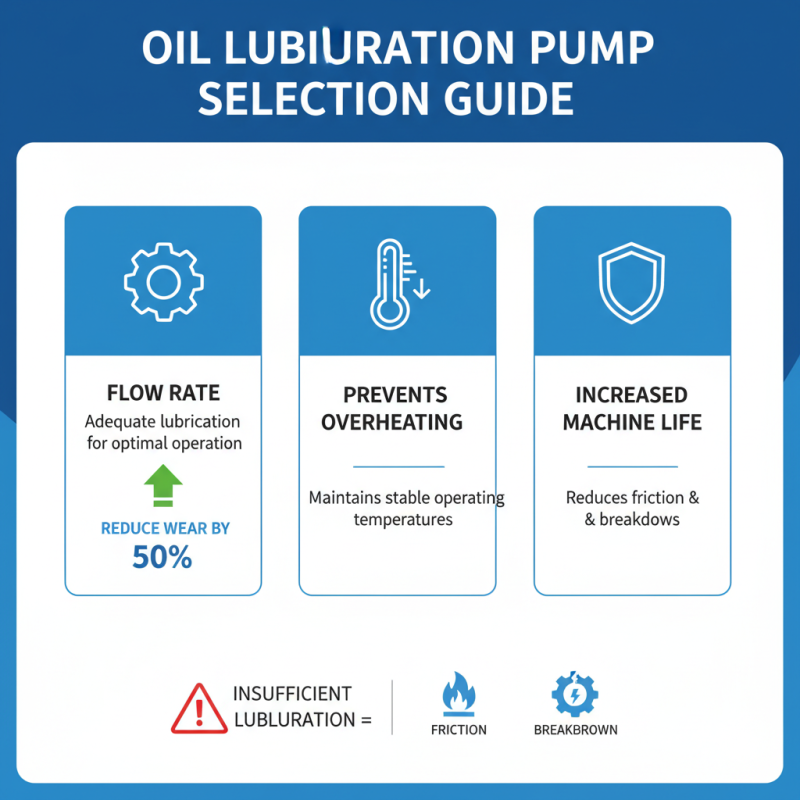

When selecting an oil lubrication pump, several key features can significantly impact machinery performance. Flow rate is crucial. A pump must provide adequate lubrication for optimal operation. Studies indicate that machines running on appropriate lubrication can reduce wear by up to 50%. Insufficient lubrication leads to increased friction, overheating, and potential breakdown.

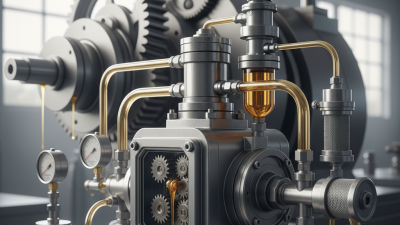

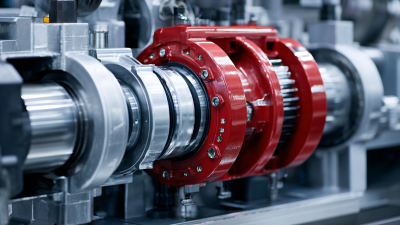

The design of the pump also plays a vital role. Positive displacement pumps are often preferred for their efficiency. They maintain consistent pressure, ensuring a steady oil supply. Additionally, consider the materials used in construction. High-quality materials resist wear and corrosion. Reports show that pumps made from durable alloys last 30% longer than those made from standard metals.

Lastly, ease of maintenance cannot be overlooked. Complex pumps may require costly service time. Simple designs allow for quick access to components. A recent survey found that 40% of machinery failures stemmed from maintenance issues. Reflecting on these aspects helps in making informed decisions. Investing in the right oil lubrication pump is crucial for long-term machinery health.

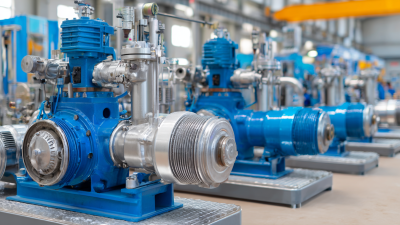

Comparative Analysis of Leading Oil Lubrication Pump Brands in 2026

In 2026, the oil lubrication pump market has seen significant growth. Many pumps are designed to improve machinery performance. However, not all pumps are created equal. Some may underdeliver, falling short of expectations despite high claims. It's essential to analyze various options carefully.

When comparing leading brands, efficiency is a key factor. Some pumps excel in reducing friction, while others focus on durability. Users report varying performance based on machine types. Not every pump performs well in all scenarios. The cost-benefit ratio also raises questions. Higher-priced options do not always guarantee superior results.

Moreover, maintenance needs can differ greatly. Certain models require frequent servicing, which can hinder productivity. A user-friendly design can make a significant difference. While researching, pay attention to real user feedback. Understanding limitations and areas for improvement can guide better choices. The right pump can enhance overall machine effectiveness. However, staying informed about product weaknesses is equally crucial.

Industry Standards and Certifications for Oil Lubrication Pumps

When selecting an oil lubrication pump, industry standards and certifications play a crucial role. These standards ensure the quality and reliability of pumps used in various machinery. Look for pumps that meet the ISO standards or those certified by reputable organizations. These certifications can indicate a pump's performance and longevity in demanding applications.

Understanding the specifications is essential. Many manufacturers provide performance data that highlights flow rates, pressure limits, and energy efficiency. These figures can help assess whether a pump meets specific needs. In some cases, the data might appear overly optimistic. This discrepancy can lead to miscalculations and eventual performance issues.

Regular inspections of lubrication systems are necessary. Even with certified pumps, wear and tear can affect efficiency. Users often overlook maintenance, which can lead to costly repairs. Evaluating operational conditions is vital. Not all pumps will suit every environment, and choices may require reevaluation over time. Staying informed about evolving standards can mitigate risks and enhance efficiency.

2026 Best Oil Lubrication Pump Performance Analysis

Impact of Oil Lubrication on Machinery Lifespan and Maintenance Costs

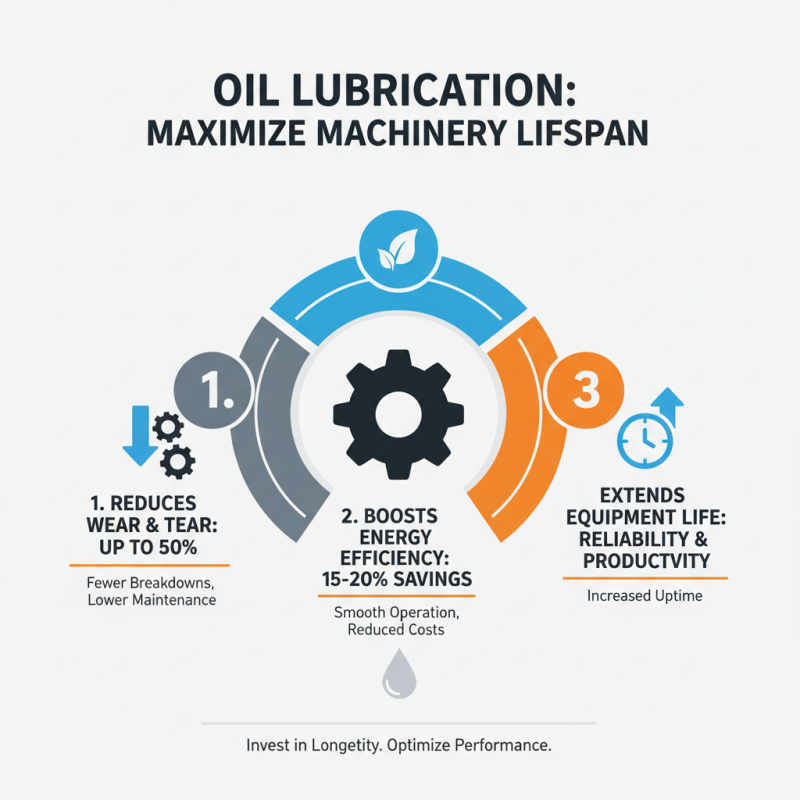

Oil lubrication plays a crucial role in enhancing the lifespan of machinery. According to industry reports, effective lubrication can reduce wear and tear on components by up to 50%. This reduction leads to fewer breakdowns and lower maintenance costs. When machines operate smoothly, they consume less energy. Energy savings can reach 15-20%, significantly benefiting operational budgets.

Choosing the right oil lubrication pump is essential. Selecting a pump that maintains consistent oil flow can directly impact machinery efficiency. Remember to check oil viscosity regularly. Too thick or too thin oil can lead to inadequate lubrication, causing potential damage. Monitoring temperature is also vital. Excessive heat can degrade oil quality and lead to mechanical failure.

Tip: Implement a scheduled maintenance routine that includes regular inspections of lubrication systems. Document findings to track trends and problem areas. Small adjustments early on can prevent costly repairs later. Always consult technical specifications of machinery to ensure compatibility with lubrication products. Pay close attention to oil filtration systems; they can trap contaminants and extend the life of equipment.

Related Posts

-

Best Oil Lubrication Pumps for Efficient Machine Performance?

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency

-

Understanding the Impact of Oil Lubrication Pumps on Equipment Longevity: Key Insights and Data

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

Top 10 Essential Pumps for Oil: Your Ultimate Buying Guide

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs