10 Best Oil Pumping Machines for Efficient Performance in 2026?

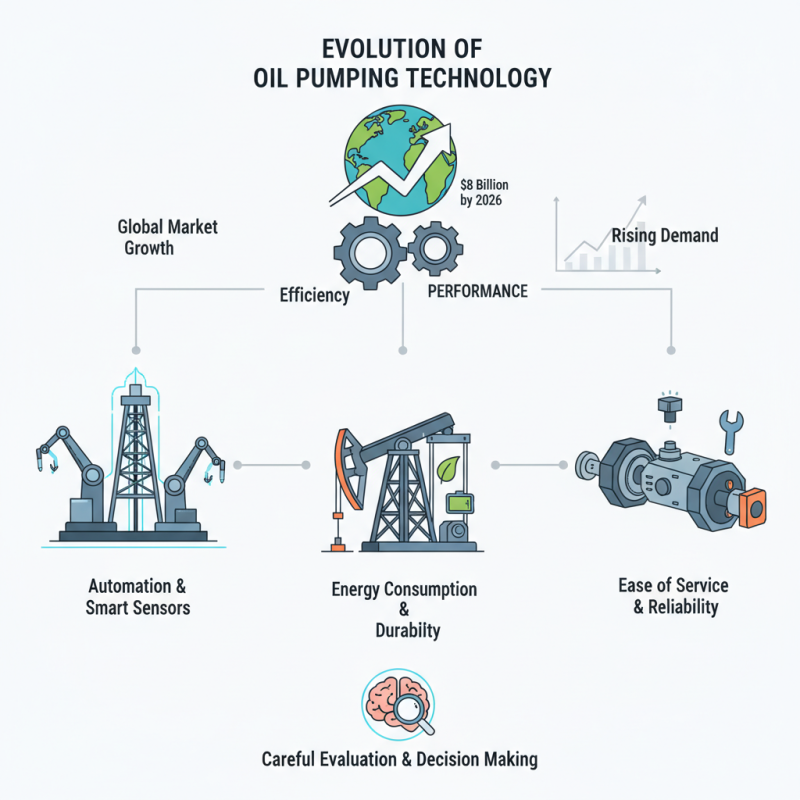

In 2026, the oil pumping machine industry is seeing rapid advancements. According to a recent report by Market Research Future, the global oil pump market is expected to reach $8 billion by 2026. This growth reflects rising demand in various sectors, including automotive and industrial applications.

Efficiency is paramount for oil pumping machines. These machines play a critical role in ensuring smooth operations in oil extraction and transportation. The right machine can significantly reduce operational costs and improve output. Manufacturers are focusing on technologies, such as automation and smart sensors, to enhance performance. However, despite these advancements, challenges remain. Some machines struggle with reliability and maintenance issues. This brings into question their long-term efficacy.

As we look ahead, selecting the best oil pumping machine is more complex than ever. Various options are available, each catering to specific needs. Potential buyers should consider factors like energy consumption, durability, and ease of service. The competition is fierce, and making the right choice is vital for operational success. The evolving landscape requires careful evaluation and thoughtful decision-making.

10 Key Factors Influencing the Efficiency of Oil Pumping Machines in 2026

Efficiency in oil pumping machines is influenced by several key factors. One significant aspect is the design and materials used in manufacturing. High-quality materials lead to better durability and performance. According to the International Energy Agency, using advanced materials can enhance efficiency by up to 15%. This is crucial for operations requiring optimal performance.

Another important factor is the operational environment. Extreme temperatures and moisture levels can impact machine performance. A study by the American Society of Mechanical Engineers indicates that machines running under unfavorable conditions can lose up to 20% of their efficiency. Regular maintenance is also essential, as it can prevent major failures. Neglecting this can lead to costly downtimes and repairs.

Moreover, technological advancements play a vital role. Automation and smart monitoring systems can significantly improve a machine's efficiency. The latest reports suggest that integrating IoT technology can boost operational efficiency by as much as 25%. However, many operators still underestimate the benefits of these innovations. There is a notable gap between technology adoption and actual performance outcomes. This area needs more focus for the industry to thrive.

10 Best Oil Pumping Machines for Efficient Performance in 2026

This chart displays the efficiency ratings of the top 10 oil pumping machines in 2026 based on factors such as energy consumption, output capacity, durability, and ease of maintenance.

Performance Metrics: Understanding Flow Rates and Pressure in Oil Pumps

When selecting an oil pumping machine, understanding performance metrics is crucial.

Flow rates and pressure are the two main metrics that define efficiency. Flow rate measures how much fluid is moved in a given time.

Higher flow rates can lead to faster operation, but may not always ensure optimal performance. It's essential to find a balance.

Pressure, on the other hand, indicates how forcefully the fluid is pushed. High pressure can help overcome resistance in pipes and fittings.

However, excessively high pressure might lead to leaks or equipment failure. Operating within safe limits is vital for long-term reliability.

Not all pumping machines excel in both metrics. Some machines perform well at high flow rates but struggle with pressure.

Others may maintain steady pressure but fall behind in flow. Evaluating these metrics against your specific needs is key.

This process can reveal hidden and prompt better choices.

Be ready to reassess your current equipment. Reflections on performance are often necessary to achieve optimal operation.

Technological Advancements: Innovations Driving Oil Pump Efficiency

The oil pumping industry is experiencing significant technological advancements. Automation plays a crucial role. Modern machines now utilize sensors to monitor performance in real time. This data is invaluable for minimizing downtime and ensuring smooth operations.

Innovative designs are also enhancing energy efficiency. Newer models consume less power. They achieve this without sacrificing performance. Engineers are focusing on the materials used in construction. Lightweight and durable materials reduce wear and tear over time. However, this reliance on advanced materials may result in higher initial costs. Users must weigh these upfront investments against long-term savings.

Data analytics is another area driving changes. It helps optimize pumping schedules based on demand. This ensures operators do not run machinery unnecessarily. Despite these benefits, there is still a challenge with data security. Protecting sensitive information from breaches is essential. As technology evolves, so must the safeguards in place. The future holds promise, but vigilance remains key.

Energy Consumption Analysis: Comparing Electric vs. Diesel Oil Pump Models

When comparing electric and diesel oil pump models, energy efficiency is a critical factor. Electric oil pumps are often touted for being cleaner and quieter. They emit fewer greenhouse gases than their diesel counterparts. According to a 2022 industry report, electric pumps can consume 30% less energy than diesel models. This makes them more appealing for businesses aiming for sustainability.

However, diesel models still hold significant advantages. They tend to offer greater power output. In high-demand situations, diesel pumps can perform better. A recent study highlighted that up to 70% of oil production in rural areas still depends on diesel due to infrastructure limitations. Additionally, diesel machines often have longer operational lives when properly maintained. This creates a complex decision-making scenario for buyers.

Costs also vary between the two types. Electric pumps may have higher initial costs due to the price of technology. Nevertheless, their lower operational costs can lead to savings over time. The energy efficiency of electric models is compelling. Yet, local conditions and availability can sway decisions heavily in favor of diesel models. Balancing performance and energy consumption remains a challenge for many users.

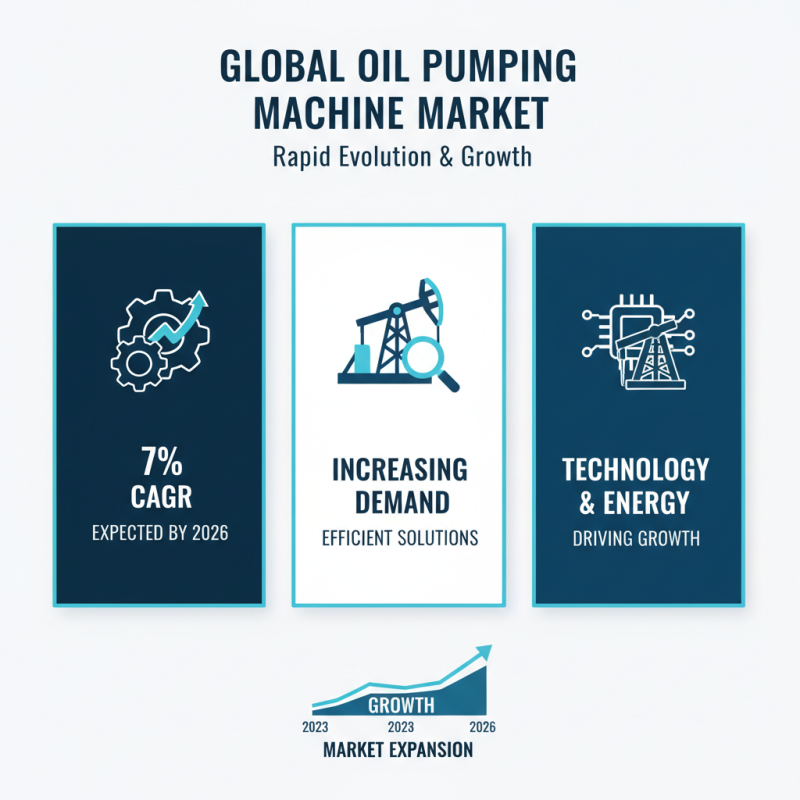

Market Trends: Projected Growth and Demand for Pumping Machines in 2026

The market for oil pumping machines is rapidly evolving. Industry analysts predict a significant growth rate through 2026. The demand for efficient pumping solutions is on the rise. According to a recent market report, the global oil pumping machine industry is expected to expand at a CAGR of 7% by 2026. This growth is driven by increasing energy needs and advancements in technology.

Companies are aggressively investing in modern pumping technologies. Efficiency and performance are key factors in their strategies. The adoption of automation and smart technology can yield notable efficiency gains. Maintenance costs can be reduced significantly with these innovations. Businesses should consider investing in real-time monitoring systems and predictive maintenance solutions. These techniques ensure optimal performance.

Tips: Evaluate your current pumping system's efficiency regularly. Consider embracing automation to boost productivity. Keep an eye on emerging technologies and trends. Staying updated is crucial for maintaining a competitive edge. Balancing cost and performance should be a continuous process.

Related Posts

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

Top 10 Essential Pumps for Oil: Your Ultimate Buying Guide

-

Why You Should Choose Air Oil Pumps for Your Industrial Needs Today