Best Oil Lubrication Pumps for Efficient Machine Performance?

In the world of machinery, efficiency is paramount. An effective oil lubrication pump plays a crucial role in maintaining optimal performance. These pumps ensure that every moving part is well-lubricated, minimizing wear and tear. Without proper lubrication, machines can falter or even break down.

Oil lubrication pumps come in various types, each suited for specific applications. Some are designed for high-pressure systems, while others work efficiently at lower pressures. Choosing the right oil lubrication pump can be challenging. It requires understanding the machine's needs and the operating environment.

Selecting an unsuitable pump may lead to inefficiencies. It's vital to assess the pump's specifications. Consider factors like flow rate and viscosity. Regular maintenance is equally important to ensure longevity. An overlooked aspect like a clogged filter or worn-out components can cause issues. Investing time in research ensures you find the best oil lubrication pump for your equipment.

Understanding the Importance of Oil Lubrication in Machinery

Oil lubrication plays a critical role in machinery performance. It reduces friction, minimizes wear, and enhances efficiency. According to industry reports, friction is responsible for up to 30% of energy loss in machinery. Effective oil lubrication can significantly cut these losses, improving energy consumption.

A key factor is the oil's viscosity. It affects how well it flows and protects surfaces. Using the wrong viscosity can lead to overheating or inadequate protection. The American Society of Mechanical Engineers indicates that proper lubrication can increase equipment lifespan by 50%. This is a compelling figure for industries reliant on heavy machinery.

However, maintaining optimal oil levels and quality can be challenging. Contaminated oil can lead to severe damage. Regular testing is essential. In a recent study, 40% of machinery failures were linked to poor lubrication practices. These insights highlight the need for meticulous monitoring and maintenance of lubrication systems.

Types of Oil Lubrication Pumps and Their Functions

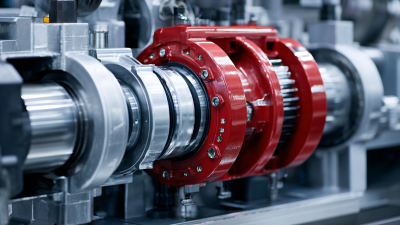

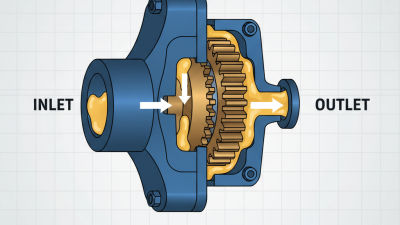

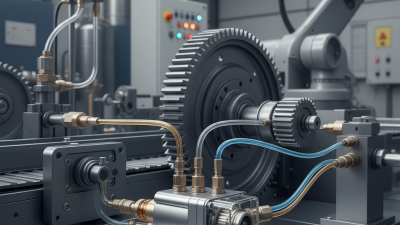

Oil lubrication pumps play a crucial role in enhancing machine performance across various industries. Understanding the different types of oil lubrication pumps helps in selecting the right one for specific applications. Positive displacement pumps are popular for their efficiency. They deliver a consistent flow of oil, which reduces wear and tear on moving parts. This type of pump is often used in heavy machinery.

Another type is the centrifugal pump. It relies on a rotating impeller to move oil. Centrifugal pumps are favored for their ability to handle large volumes of fluid. However, they may lose efficiency at lower flow rates. Progressing cavity pumps offer a solution for varying viscosity levels. Their design allows for smooth operation, even with thick oils. Yet, these pumps can be complicated and require regular maintenance.

Regular maintenance is essential for all types of oil lubrication pumps to ensure optimal performance. Neglecting this can lead to reduced flow and increased friction. Understanding the right pump for your machinery can make a difference. Identify your needs clearly before making a choice. This will help avoid costly mistakes and improve overall efficiency. Choosing the right pump type is not always straightforward, and re-evaluating options periodically is wise.

Best Oil Lubrication Pumps for Efficient Machine Performance

| Type of Pump | Function | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Positive Displacement Pumps | Provides a constant flow of oil at high pressure | Industrial machinery, engine lubrication | High precision, consistent flow | Can be costly, requires maintenance |

| Gear Pumps | Uses rotating gears to move oil | Hydraulic systems, machine tools | Simple design, reliable operation | Limited to higher viscosity oils |

| Centifugal Pumps | Rely on rotational energy for fluid movement | Oil refineries, process industries | High flow rates, efficient for low-viscosity oils | Not suitable for high viscosity fluids |

| Diaphragm Pumps | Uses a diaphragm to transfer oil | Pumping hazardous materials, oil extraction | Can handle corrosive liquids, low maintenance | Lower flow rates compared to other types |

| Electric Pumps | Utilizes electric power for oil movement | Automated lubrication systems | Automated control, energy efficient | Initial setup costs can be high |

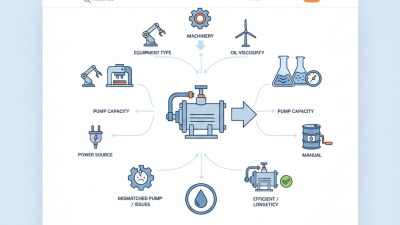

Factors to Consider When Choosing an Oil Lubrication Pump

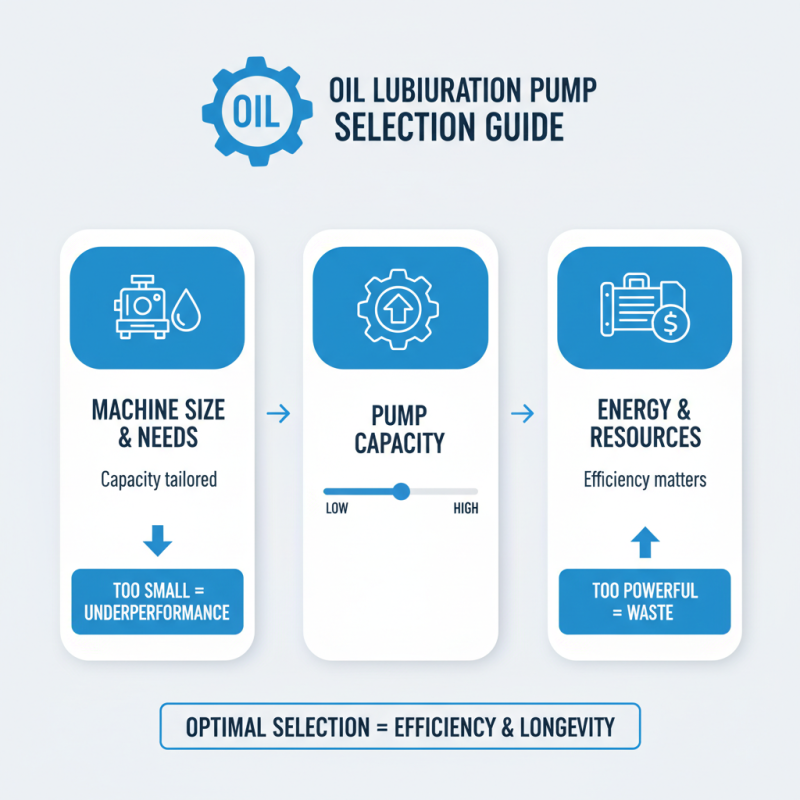

When choosing an oil lubrication pump, several factors come into play. Consider the pump's capacity. This depends on your machine's size and lubrication needs. A pump that is too small will underperform. Conversely, a pump that is excessively powerful may waste energy and resources.

Also, check the pump's material. Durable materials like stainless steel can extend the pump's lifespan. In contrast, cheaper materials might corrode or fail sooner. This will affect your machine's performance negatively. Make sure the pump matches the fluid viscosity. Thick oils require strong pumps; thinner oils need less force.

Tips: Always assess maintenance requirements. A simpler design often leads to easier upkeep. Remember, a pump that is hard to maintain may lead to downtime. Monitor energy efficiency too. High-performance pumps can save money long-term. Finally, test the pump in real conditions if possible. Something may look great on paper but may not deliver in practice.

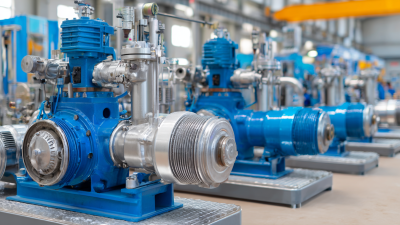

Top Oil Lubrication Pumps for Different Machine Applications

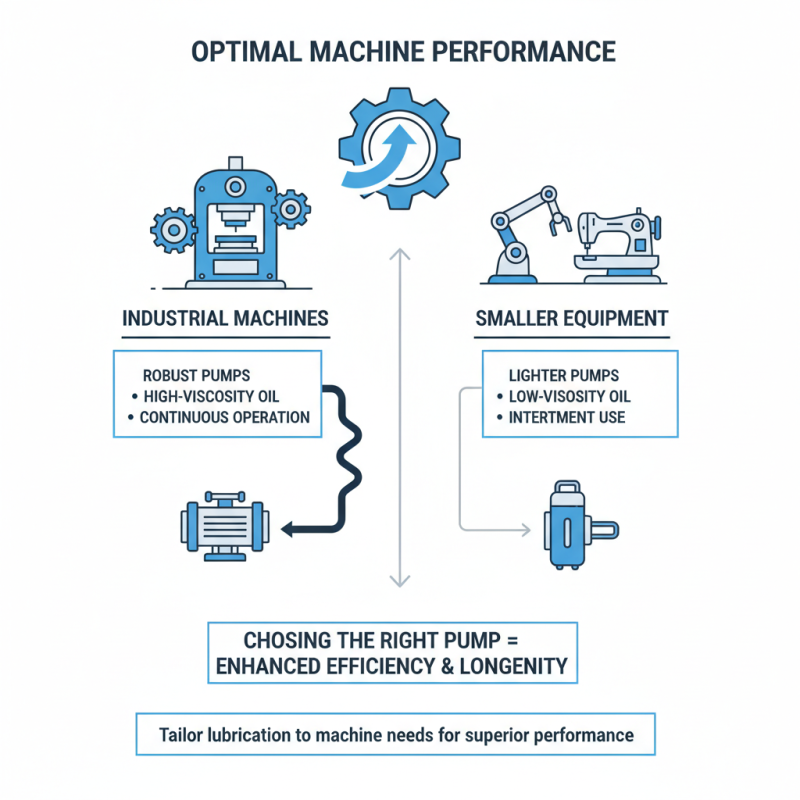

Choosing the right oil lubrication pump can greatly enhance machine performance. Different machines require specific types of pumps. Understanding these needs is essential. For instance, industrial machines may demand robust pumps that can handle high viscosity oil. Conversely, lighter pumps suit smaller equipment.

When selecting a pump, consider the oil type and temperature range. High temperatures can affect pump efficiency. Look for compatibility with the fluids your machines use. Some pumps provide better flow rates at higher temperatures, improving overall operation.

Tips: Regular maintenance is vital. Inspect the pump for leaks or wear. Replace filters regularly to ensure clean oil flow. Monitoring oil levels can prevent machine damage. Always keep a record of maintenance activities for future reference.

Maintenance Tips for Enhancing Pump Efficiency and Longevity

Maintaining oil lubrication pumps is crucial for optimal machine performance. Regular checks can significantly enhance their efficiency. Keep an eye on oil levels. Low levels could lead to increased wear and tear. A pump running low on oil may overheat.

Another vital maintenance tip involves cleaning. Dirt and debris can clog filters and affect pump function. Clean filters regularly to ensure smooth operation. In places with high dust, consider more frequent cleaning sessions.

Monitor the temperature of the pump. It should remain within the recommended range. Elevated temperatures can signal issues. If the pump runs hot, investigate promptly. Addressing these can prevent failures. Reflect on the condition of your equipment. Regular upkeep ensures you avoid deeper problems down the line.

Best Oil Lubrication Pumps for Efficient Machine Performance

This chart displays the performance ratings of various oil lubrication pumps, showcasing their efficiency in maintaining machine performance. A higher rating indicates better performance.

Related Posts

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

Understanding the Impact of Oil Lubrication Pumps on Equipment Longevity: Key Insights and Data

-

How to Choose the Right Lubrication Pump for Your Needs

-

How to Choose the Right Oil Lubrication Pump for Your Needs

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights