2026 Best Rotary Positive Displacement Pumps for Optimal Performance?

As the industry looks ahead to 2026, the pursuit of optimal performance in rotary positive displacement pumps has never been more critical. Experts like Dr. Alice Greene, a leading authority in fluid dynamics, emphasize the importance of efficiency. She stated, "Choosing the right rotary positive displacement pump can make or break your operation." This underscores the stakes involved in selecting the best equipment.

The rotary positive displacement pumps market is rapidly evolving. New technologies promise improvements in efficiency and reliability, but these advancements come with challenges. Identifying the best options requires careful consideration of various factors, including design, materials, and operating conditions.

While many products claim to deliver superior performance, not all live up to expectations. Users often encounter issues such as wear and tear, leading to inefficiency. It’s essential to evaluate pump capabilities critically. Investing in education and research about rotary positive displacement pumps can lead to better purchasing decisions. We must continue exploring to ensure we choose the best solutions for our needs in 2026 and beyond.

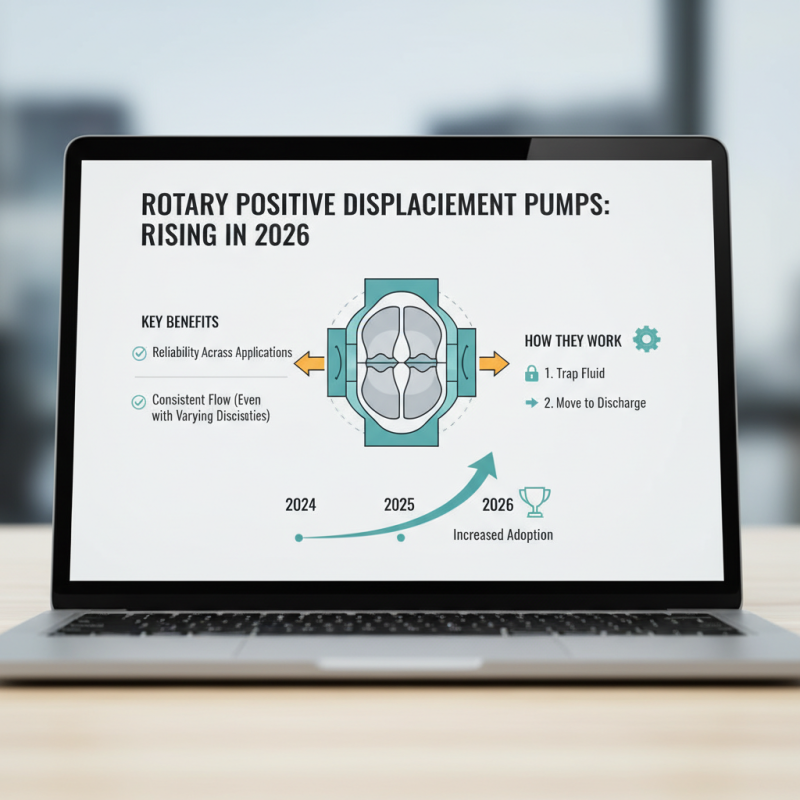

Overview of Rotary Positive Displacement Pumps in 2026

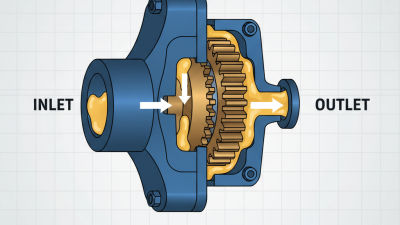

Rotary positive displacement pumps are gaining attention in 2026. They offer reliability for a range of applications. These pumps work by trapping fluid and moving it through a discharge. Their design ensures a consistent flow, even with varying viscosities.

The growing need for efficiency places these pumps in high demand. Industries are increasingly adopting them for their durability. Overall, they can handle fluids of different properties. However, the complexity of maintenance can be a concern. Users often face challenges with wear and tear.

Innovations in materials are shaping the future of these pumps. More resilient components extend their lifespan. Yet, there remains room for improvement in energy consumption. Continuous feedback from users is crucial. This helps manufacturers refine their designs. Enhanced performance is possible, but reaching it demands a collective effort.

Key Features That Define Optimal Performance in Pumps

When assessing rotary positive displacement pumps, key features greatly influence performance. Efficiency tops the list. According to industry reports, efficient pumps can boost energy savings by up to 20%. This is vital for reducing operational costs. Operating at optimal pressure levels also enhances lifespan. A balance of pressure and flow rate can lead to fewer maintenance issues.

Durability plays a crucial role too. Pumps made with high-quality materials often last longer, even under harsh conditions. A 2022 study revealed that pumps with advanced coatings can resist corrosion and wear, extending use by 30%. Many users overlook this aspect. It’s easy to focus only on initial costs rather than long-term value.

Another factor is ease of maintenance. Pumps designed for quick disassembly save time and labor costs. Reports indicate that simpler maintenance can reduce downtime by 15%. Users need to reflect on their current systems. Are they overlooking these critical features? Balancing efficiency, durability, and maintenance needs is essential for optimal performance.

Top Brands and Models of Rotary Positive Displacement Pumps

Rotary positive displacement pumps are crucial in many industries. They ensure efficient fluid transfer, which is vital for operational success. Key market reports indicate that these pumps comprise a significant portion of the global pump market, projected to reach over $20 billion by 2026. Their reliability is unmatched, making them ideal for various applications.

Several top models stand out due to their performance and durability. The advantages include excellent efficiency and low pulsation flow. However, even the best pumps can face limitations, such as wear and maintenance issues. Regular inspections are necessary. Some models may fall short in specific environments. The right choice depends on the fluid type and operating conditions.

User feedback reveals mixed experiences. While many operators praise these pumps for their efficiency, others report challenges with adaptability. This highlights the necessity of thorough evaluation before selecting a pump. Choosing the right model can greatly enhance performance, but awareness of potential drawbacks is crucial for optimal operation.

Performance Comparison of Rotary Positive Displacement Pumps (2026)

Comparative Analysis of Pump Efficiency and Reliability

When choosing rotary positive displacement pumps, efficiency and reliability are crucial. Evaluating these factors can enhance operational outcomes. Consider the pump design. A well-engineered pump can reduce energy costs while ensuring consistent flow rates. Look into the material used. Some materials resist wear and tear better, prolonging the pump's lifespan.

Tips: Regular maintenance is vital. Check for leaks and unusual noises. This can prevent costly repairs later. Additionally, ensuring proper alignment can avoid premature failure. A misaligned pump may not show immediate issues, but it can lead to significant problems over time.

Another factor is the operating conditions. High temperatures or abrasive fluids can impact performance. Pumps may struggle under these conditions. Careful selection based on the specific application can make a difference. Evaluate how the pump interacts with the fluid. This consideration can help in understanding efficiency levels better.

Tips: Always test the pump under real conditions before full-scale implementation. This helps identify any unforeseen challenges. Monitor performance consistently, and be ready to adjust parameters as needed. Balancing efficiency with reliability gives the best outcomes.

Applications and Industries Benefiting from Advanced Pump Technology

Rotary positive displacement pumps play a crucial role across various industries. They are widely used in manufacturing, agriculture, and food processing. These pumps excel in handling viscous fluids. Their ability to maintain a constant flow rate makes them ideal for precision applications. In food production, they ensure consistent ingredient dosing. This consistency is vital for quality control.

The chemical industry also benefits significantly from advanced pump technology. Rotary pumps can handle corrosive materials safely. Their design minimizes the risk of contamination. This is essential for maintaining product integrity. However, not all pump selections lead to optimal performance. Some users report issues due to improper sizing or selection. Regular maintenance is often overlooked. Neglect can lead to reduced efficiency and even pump failure.

In pharmaceuticals, precision is paramount. Here, rotary positive displacement pumps are indispensable. They enable accurate transfer of sensitive liquids. Yet, some facilities struggle with the complexity of these systems. Training staff can be challenging. It is essential to understand the system's nuances. Mistakes in operation may lead to costly errors. Reflecting on these challenges can lead to better practices and improved outcomes.

Related Posts

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

Top 5 Positive Displacement Pump Manufacturers You Should Know About

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

High Pressure Screw Pump Tips for Optimal Performance and Maintenance

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

Top 10 Best Tar Pumps for Efficient Liquid Transfer Solutions