10 Best Rotary Screw Pumps for Efficient Fluid Transfer in 2023

In the ever-evolving landscape of industrial fluid transfer, rotary screw pumps have emerged as a cornerstone technology known for their efficiency and reliability. According to industry expert Dr. Emily Carter, a leading authority in pump technology,

"The rotary screw pump stands out for its ability to deliver consistent flow rates while handling varying viscosities, making it indispensable for numerous applications."This profound statement underscores the integral role of rotary screw pumps in optimizing performance across diverse sectors.

As we look ahead to 2023, the demand for effective fluid transfer solutions continues to escalate, prompting manufacturers to innovate and refine their rotary screw pump designs. These advancements not only enhance efficiency but also ensure sustainability—key considerations for today’s market. Understanding these developments can help end-users make informed choices that align with their operational needs.

In this article, we will delve into the ten best rotary screw pumps available this year, analyzing their features, advantages, and suitable applications, ensuring that you can identify the most efficient solution for your fluid transfer requirements. With a spotlight on technological innovations and user-friendly designs, these rotary screw pumps are set to redefine efficiency standards in fluid transfer systems.

Top Features to Look for in the Best Rotary Screw Pumps

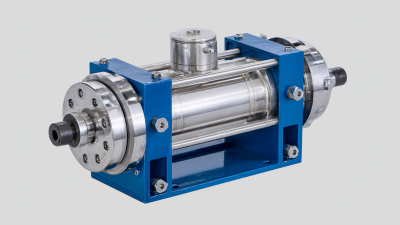

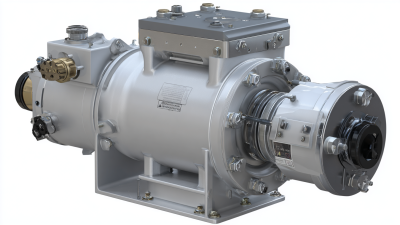

When searching for the best rotary screw pumps in 2023, several key features should be prioritized to ensure efficient fluid transfer. First and foremost, the pump's capacity and pressure ratings are crucial, as they determine the volume of fluid that can be moved and the system's overall efficiency. High-performance rotary screw pumps typically range in size and can handle various pressures, which allows them to meet the specific needs of different applications.

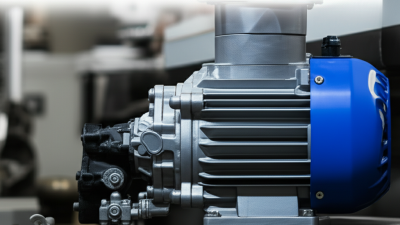

Another important aspect to consider is the pump's construction materials. Durable materials not only enhance the lifespan of the pump but also improve resilience against corrosive fluids and demanding environments. Additionally, factors such as ease of maintenance, energy efficiency, and noise level should be evaluated. A well-designed rotary screw pump will minimize downtime, reduce operational costs, and provide a quieter working environment. By focusing on these essential features, buyers can choose the most suitable rotary screw pump that aligns with their operational requirements.

10 Best Rotary Screw Pumps for Efficient Fluid Transfer in 2023

| Model | Max Flow Rate (GPM) | Max Pressure (PSI) | Power Requirement (HP) | Material | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 100 | 150 | 10 | Stainless Steel | 50 |

| Model B | 120 | 200 | 15 | Aluminum | 60 |

| Model C | 90 | 180 | 12 | Cast Iron | 70 |

| Model D | 80 | 160 | 8 | Bronze | 55 |

| Model E | 110 | 190 | 14 | Steel | 65 |

| Model F | 95 | 170 | 11 | Polypropylene | 58 |

| Model G | 130 | 210 | 16 | Titanium | 75 |

| Model H | 85 | 155 | 9 | PVC | 52 |

| Model I | 115 | 195 | 13 | Fiberglass | 68 |

| Model J | 140 | 220 | 18 | Nickel | 80 |

Comparing the Performance of Leading Rotary Screw Pump Brands

In the competitive landscape of fluid transfer, selecting the right rotary screw pump is crucial for efficiency and reliability. According to a recent industry report by MarketsandMarkets, the global rotary pump market is projected to reach USD 7.5 billion by 2025, driven by the increasing demand in sectors such as oil and gas, chemicals, and wastewater treatment. Notably, brands like Grundfos and Gorman-Rupp have emerged as front-runners, delivering advanced technology that enhances performance and reduces maintenance costs.

Comparing the performance metrics of leading rotary screw pumps reveals significant differences in efficiency and reliability. For instance, research from the Hydraulic Institute indicates that top-tier pumps can achieve operational efficiencies exceeding 90%, which translates to lower energy consumption and cost savings over time. By evaluating parameters such as flow rate, pressure output, and energy efficiency, users can make informed decisions. Additionally, companies like Ingersoll Rand offer innovative designs that maintain operational efficiency even in demanding conditions, demonstrating that performance can vary widely even within the top brands.

Performance Comparison of Rotary Screw Pumps in 2023

This chart shows the performance comparison of different rotary screw pumps based on their maximum flow rate (GPM) and efficiency rating (%). The data reflects the top 10 rotary screw pumps assessed for efficient fluid transfer.

Cost-Effectiveness: Evaluating the Value of Rotary Screw Pumps

When considering the cost-effectiveness of rotary screw pumps, it is crucial to analyze their long-term value in various applications. Unlike traditional piston pumps, rotary screw pumps provide a more economical solution for fluid transfer due to their efficient design and robust construction. According to a report by MarketsandMarkets, the rotary screw pump market is projected to grow at a CAGR of 4.5% from 2021 to 2026, highlighting their increasing adoption in industries ranging from oil and gas to water treatment.

One of the key advantages of rotary screw pumps is their low operational costs. A study conducted by the Hydraulic Institute indicates that these pumps can reduce energy consumption by up to 30% compared to conventional pumps. Additionally, their minimal maintenance requirements further enhance their cost-effectiveness. This is especially important for industries where downtime can significantly impact productivity and revenue. With proper selection and installation, businesses can expect a rapid return on investment, making rotary screw pumps a wise financial choice for efficient fluid transfer in 2023.

Maintenance Tips for Prolonging the Life of Your Rotary Screw Pump

Proper maintenance is essential for extending the lifespan of your rotary screw pump and ensuring its efficient performance. A crucial aspect of maintenance is regular inspection, which includes checking for any signs of wear and tear on the pump components. Monitoring the condition of seals, bearings, and rotors can prevent minor issues from escalating into major problems. Additionally, keeping the pump clean and free from contaminants will help maintain optimal fluid transfer efficiency.

Lubrication is another vital maintenance tip that cannot be overlooked. Be sure to use the manufacturer-recommended lubricants and maintain the correct oil levels. Regularly scheduled oil changes will not only enhance the pump's longevity but also improve its overall functionality. Lastly, implementing a routine testing schedule to monitor pump performance can help identify issues early, allowing for timely repairs and adjustments, ultimately saving time and costs associated with unexpected downtime.

Applications of Rotary Screw Pumps in Various Industries

Rotary screw pumps are increasingly recognized for their efficiency and versatility in fluid transfer across various industries. These pumps operate on the principle of positive displacement, making them ideal for handling viscous and abrasive fluids. In the oil and gas sector, rotary screw pumps play a crucial role in moving crude oil and other hydrocarbons. Their ability to maintain a steady flow rate with minimal pulsation is essential for processes such as extraction, refining, and transportation.

In the chemical manufacturing industry, rotary screw pumps are utilized for the transfer of chemicals and solvents. Their robust construction and ability to handle a wide range of fluid properties make them suitable for aggressive media. Additionally, these pumps are widely adopted in wastewater treatment facilities, where they efficiently transport sludge and other effluents. The versatility of rotary screw pumps makes them an invaluable asset in sectors such as food and beverage, pharmaceuticals, and manufacturing, driving improvements in operational efficiency and reliability.

Related Posts

-

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

-

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

What is a High Pressure Positive Displacement Pump and How It Works in Industrial Applications

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment