Why You Should Choose Air Oil Pumps for Your Industrial Needs Today

In the ever-evolving landscape of industrial machinery, the choice of components can significantly impact operational efficiency and overall productivity. Air oil pumps, a crucial element in various applications, have gained recognition for their reliability and versatility. According to industry expert Dr. Ella Thompson, a renowned mechanical engineer and author specializing in fluid dynamics, "Air oil pumps are not just a component; they are a pivotal investment that enhances operational fluidity and prolongs machine life." This statement underscores the critical importance of selecting the right pumps to meet industrial needs.

As manufacturers increasingly seek solutions that optimize performance while reducing downtime, air oil pumps stand out for their efficiency and ease of maintenance. Unlike traditional pumps, air oil pumps utilize air pressure to deliver a consistent flow of oil, ensuring equipment runs smoothly. This innovative technology is not only beneficial for enhancing productivity but also contributes to sustainability by minimizing waste.

With an array of advantages, including energy efficiency and reduced wear and tear on systems, the decision to incorporate air oil pumps into industrial setups is a smart move for businesses aiming to stay competitive in today's market. As we delve deeper into the benefits of air oil pumps, it becomes clear why they are the preferred choice for forward-thinking manufacturers looking to enhance their operational capabilities.

Benefits of Air Oil Pumps for Industrial Applications

Air oil pumps offer a variety of benefits for industrial applications, making them an invaluable asset in modern manufacturing and maintenance processes. According to a report by the National Lubricating Grease Institute (NLGI), the efficiency of lubrication systems greatly impacts the lifespan of machinery and equipment, with well-lubricated machinery experiencing up to 30% less wear. Air oil pumps facilitate precise, high-volume lubrication, ensuring that every component receives adequate oil distribution, which is crucial for maintaining operational efficiency and reducing downtime.

Additionally, air oil pumps contribute to enhanced safety and environmental compliance. A study conducted by the International Association of Machinery and Equipment Inspectors (IAMMEI) highlighted that implementing air oil lubrication systems can reduce leaks and spills by over 50%, minimizing contamination risks in the workplace. These systems also enable more accurate dosing, significantly reducing the excess oil that can lead to environmental harm. By adopting air oil pump technology, industries not only boost productivity but also adhere to stricter environmental regulations, aligning with sustainable practices that are increasingly important in today's industrial landscape.

Benefits of Air Oil Pumps for Industrial Applications

This chart illustrates the key benefits of using air oil pumps for industrial applications. Each benefit is rated on a scale of 1 to 10, highlighting their significance in improving operational efficiency, reducing costs, ensuring durability, facilitating maintenance, and minimizing environmental impact.

Understanding the Mechanism of Air Oil Pumps

Air oil pumps have gained tremendous traction in various industrial applications due to their unique operating mechanism. At their core, these pumps utilize compressed air to efficiently move oil from one location to another, serving a critical role in lubrication systems. According to a report by the International Journal of Engineering and Technology, air oil pumps can reduce energy consumption by up to 30% compared to traditional electric pumps, making them a more eco-friendly and cost-effective alternative.

One of the standout features of air oil pumps is their ability to handle viscous fluids without overheating, thanks to their innovative design. The integration of a regulator allows for precise control over oil flow, which enhances equipment lifespan and reliability. Moreover, industries such as automotive and manufacturing have reported improved operational efficiency when incorporating these pumps into their systems, with downtime reduced by as much as 20%, according to a recent market analysis by ResearchAndMarkets.com.

**Tips:** When considering air oil pumps for your facility, ensure that you assess your specific lubrication requirements and the compatibility of the fluids used. Regular maintenance checks are also crucial to ensure optimal performance and longevity of the pumps. Additionally, investing in quality air filters can significantly enhance the operation, preventing contamination that could compromise the pump's efficiency.

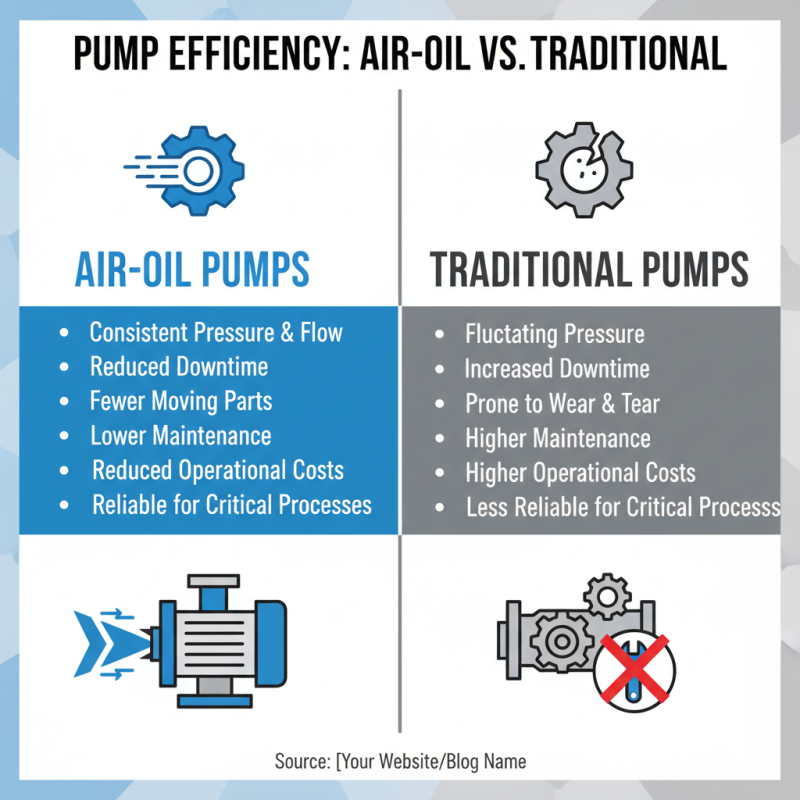

Comparative Analysis: Air Oil Pumps vs. Traditional Pumps

When evaluating the efficiency of air oil pumps versus traditional pumps, several factors come into play. Air oil pumps are known for their ability to deliver consistent pressure and flow, which can significantly reduce downtime in industrial applications. Unlike traditional pumps that often rely on mechanical components that can wear out over time, air oil pumps utilize compressed air to create a smooth and continuous flow. This minimizes maintenance needs and lowers operational costs, making them a more reliable choice for critical processes.

Moreover, air oil pumps are typically lighter and more compact than their traditional counterparts, allowing for easier installation and mobility within industrial settings. Their adaptability to various environments and conditions further enhances their appeal, making them suitable for use in areas where traditional pumps may falter due to debris or corrosive substances. Additionally, the energy efficiency of air oil pumps is noteworthy, often resulting in lower energy consumption compared to the electric motors that power traditional pumps. These advantages underscore the rationale for choosing air oil pumps for industrial needs, particularly when seeking robust performance and long-term savings.

Factors to Consider When Selecting Air Oil Pumps

When selecting air oil pumps for industrial applications, several critical factors must be considered to ensure optimal performance and efficiency. One of the most important elements is the pump's output capacity. According to the Fluid Power Journal, industries often require pumps that can handle varying flow rates, with commercial models typically ranging from 0.5 to 10 gallons per minute (GPM). Matching the pump's output with the system's demand is essential to avoid underperformance and potential machinery downtime.

Another crucial aspect is the operating pressure of the air oil pump. Data from the International Fluid Power Society indicates that many industrial applications require pumps that can operate at pressures ranging from 60 to 150 PSI. Higher pressure capabilities are essential for applications involving heavy machinery or hydraulic systems. Additionally, the durability and materials used in the construction of the pump should align with the working environment. Pumps constructed with corrosion-resistant materials, such as stainless steel, are recommended for environments that expose equipment to harsh chemicals or moisture, significantly extending the lifespan of the pump in industrial settings.

Common Applications of Air Oil Pumps in Industry

Air oil pumps are becoming increasingly vital across various industrial applications due to their efficiency and reliability. These pumps are widely used in sectors such as automotive, manufacturing, and food processing, where precise lubrication is crucial for maintaining machinery performance. By using air oil pumps, industries can ensure consistent oil distribution, reducing wear and tear on equipment, which ultimately leads to lower maintenance costs and prolonged machinery lifespan.

The projected growth of the global market for various air pump technologies underscores the demand for air oil pumps. With the global silent air pump market expected to escalate from $0.21 billion in 2024 to $10.31 billion by 2033, at a compound annual growth rate of 5.1%, companies are recognizing the advantages of incorporating these systems into their operations. Similarly, the monobloc air source heat pump market is anticipated to grow from $1.8 billion in 2023 to $3.2 billion by 2032. This trend highlights a significant shift towards air-based solutions, reinforcing the value of air oil pumps in meeting modern industrial needs.

Why You Should Choose Air Oil Pumps for Your Industrial Needs Today - Common Applications of Air Oil Pumps in Industry

| Application | Industry | Benefits |

|---|---|---|

| Lubrication Systems | Manufacturing | Reduces wear and tear, increases equipment lifespan |

| Hydraulic Power Units | Construction | Efficient power distribution, versatile applications |

| Oil Transfer | Oil & Gas | Rapid transfer rate, minimizes environmental impact |

| Spray Applications | Automotive | Uniform coating, improved surface quality |

| Air-Oil Lubrication | Textile | Reduced maintenance costs, enhanced machine efficiency |

Related Posts

-

Top 10 Essential Pumps for Oil: Your Ultimate Buying Guide

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

Understanding the Impact of Oil Lubrication Pumps on Equipment Longevity: Key Insights and Data

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications