How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

In the world of engine maintenance, selecting the proper lube oil pump is crucial for achieving optimal performance and longevity. As industry expert John Smith, a renowned engineer with over 20 years of experience in lubrication systems, emphasizes, “The right lube oil pump not only ensures efficient oil circulation but also protects your engine from wear and tear.” This highlights the importance of understanding the various factors involved in choosing a lube oil pump that meets specific engine requirements.

Choosing the ideal lube oil pump requires consideration of multiple aspects, including pump type, compatibility with the engine, and the specific application demands. Whether you're working with heavy machinery or a high-performance vehicle, each scenario demands a tailored approach to ensure that the lube oil pump functions effectively. By delving into the key characteristics and operational needs of your engine, you can make an informed choice that not only enhances performance but also contributes to the overall health of your machinery.

As we navigate through the essential steps and considerations for selecting a lube oil pump, it is vital to equip ourselves with the knowledge and insights necessary to make sound decisions. A well-chosen lube oil pump can serve as the backbone of your engine maintenance strategy, ensuring smooth operation and extending the life of your engine components. Let us explore the crucial guidelines for choosing the right lube oil pump to meet your specific needs.

Understanding the Importance of Lube Oil Pumps in Engine Maintenance

Lube oil pumps play a critical role in the overall maintenance and performance of engines, ensuring that all moving parts remain adequately lubricated. This lubrication is essential for reducing friction, which can lead to wear and tear over time. Without an efficient lube oil pump, oil circulation can falter, resulting in excessive heat and potentially catastrophic engine failure. Understanding how these pumps work and their importance can help in making informed decisions when it comes to engine upkeep.

Moreover, selecting the right lube oil pump tailored to your specific engine requirements is vital for optimal performance. Factors such as oil viscosity, engine size, and operating conditions should all be considered to ensure that the pump can deliver the necessary flow and pressure. An appropriate lube oil pump not only enhances engine longevity but also improves fuel efficiency, contributing to overall operational effectiveness. Regular checks and timely maintenance of the pump itself can prevent issues before they escalate, highlighting the integral role this component plays in the health of your engine.

Factors to Consider When Selecting a Lube Oil Pump for Your Engine

When it comes to selecting the right lube oil pump for engine maintenance, several critical factors should be considered to ensure optimal performance and longevity of the engine. One of the foremost aspects is the pump's flow rate, which should match the engine specifications. According to a report by the Society of Automotive Engineers, an inappropriate flow rate can lead to insufficient lubrication, resulting in increased wear and possible engine failure. Therefore, it's vital to consult your engine manual to determine the required flow rate and choose a pump that meets or exceeds this specification.

Another factor to consider is the viscosity of the oil being used. Different types of engines and operating environments require oils with varying viscosities, and the pump must be capable of handling these differences. A study from the American Petroleum Institute emphasizes that selecting a pump designed for the specific viscosity range of the oil can significantly enhance efficiency and reliability. Additionally, compatibility with the oil type is crucial, as certain pumps may not perform well with synthetic oils compared to mineral options.

Tip: Always check the temperature ratings of the lube oil pump to ensure it can withstand your engine's operating conditions. Look for pumps that are constructed with materials resistant to heat and corrosion for added durability.

When it comes to installation and maintenance, ease of service is another key consideration. Opt for pumps that offer simple installation processes and readily available replacement parts. This can significantly reduce downtime and maintenance costs in the long run. As highlighted in a recent report by the International Engine Research Institute, maintenance practices that involve proactive monitoring of pump performance can lead to a 20% reduction in unexpected failures.

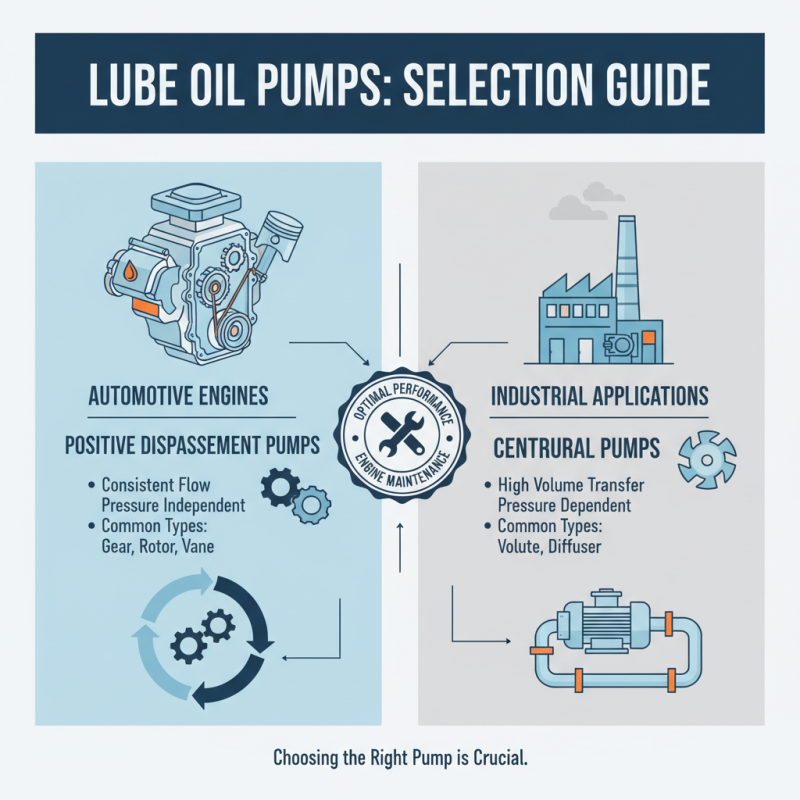

Types of Lube Oil Pumps and Their Applications in Automotive and Industrial Use

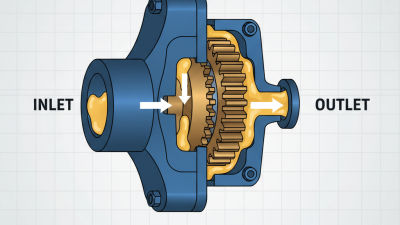

When it comes to engine maintenance, selecting the appropriate lube oil pump is essential for ensuring optimal performance. There are several types of lube oil pumps available, each suited for specific applications in both automotive and industrial settings. Positive displacement pumps, for instance, are commonly used in automotive engines due to their ability to deliver a consistent flow rate regardless of pressure changes. In contrast, centrifugal pumps are frequently utilized in industrial applications, where large volumes of oil must be moved efficiently.

A report by the International Energy Agency indicates that proper lubrication in engines can enhance fuel efficiency by up to 5%. This highlights the importance of using the right lube oil pump, which not only affects lubrication quality but also overall engine lifespan. For automotive applications, gear pumps are another popular choice, as they provide reliable operation under varying conditions, ensuring that all engine components receive adequate lubrication.

Tips for selecting the right lube oil pump include evaluating the viscosity of the oil being used, the required flow rate, and the operating pressure of the system. Additionally, it's crucial to consider the pump's construction material, especially in industrial applications where exposure to harsh environments is common. By understanding the specific needs of your engine, you can make an informed decision that will lead to improved maintenance outcomes and increased engine durability.

Key Specifications and Features to Look for in a Lube Oil Pump

When selecting a lube oil pump for your engine maintenance needs, several key specifications and features should guide your decision. First, consider the pump type: positive displacement pumps and centrifugal pumps are commonly used for engine oil applications. Positive displacement pumps, such as gear and diaphragm pumps, are known for their ability to maintain a consistent flow rate regardless of changes in pressure, making them ideal for applications requiring precise lubrication. According to a recent industry report, such pumps can achieve efficiencies of over 90%, greatly reducing the risk of over- or under-lubrication.

Another critical feature to evaluate is the pump's flow rate, which must align with the specific requirements of your engine. Typically, lube oil pumps should provide a flow rate sufficient to meet the demand of the engine under various operational conditions, and an optimal flow rate ranges between 2 to 8 gallons per minute for most medium to large engines. Additionally, the pump’s construction materials should include corrosion-resistant alloys to withstand exposure to harsh lubricants and prevent premature wear. The durability and lifespan of the pump are often correlated with its material composition and engineering design, with many high-quality pumps showing operational lifetimes exceeding 5,000 hours, as noted in mechanical reliability studies.

Lastly, consider the pump’s installation and maintenance features. A user-friendly design that allows for easy installation and routine servicing can significantly enhance operational efficiency. Features such as quick-connect fittings, built-in filters, and adjustable pressure controls are advantageous. Reports suggest that pumps designed with these considerations in mind can lead to up to 25% lower maintenance costs over time, emphasizing the importance of selecting a lube oil pump that meets not only current requirements but also future maintenance needs.

Maintenance Tips for Ensuring Optimal Performance of Lube Oil Pumps

Proper maintenance of lube oil pumps is crucial for ensuring the optimal performance of any engine system. According to a report by the Society of Automotive Engineers, approximately 30% of engine failures can be attributed to lubrication issues, highlighting the importance of regular maintenance and inspection of lube oil pumps. Routine checks on the pump's seals, filters, and overall operational efficiency can prevent costly breakdowns and extend the lifespan of the engine. It's recommended to replace oil filters every 5,000 to 7,500 miles, which can significantly improve the lubrication system's performance and maintain the pump's integrity.

In addition to regular inspections, monitoring the operating conditions of the lube oil pump is essential. Research indicates that excessive temperature fluctuations can lead to premature wear on pump components, thereby affecting the entire lubrication system's stability. To mitigate this, operators should ensure that the pump operates within the manufacturer's recommended temperature range and that any deviations are promptly addressed. Further, employing advanced monitoring technologies can provide real-time feedback on pump performance and help identify potential issues before they escalate, ultimately contributing to a more reliable engine maintenance strategy.

Related Posts

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

-

2025 How to Choose the Right Positive Displacement Water Pump for Your Needs

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

Why Choose a Screw Vacuum Pump for Your Industrial Applications