2025 How to Choose the Right Positive Displacement Water Pump for Your Needs

When it comes to selecting the right equipment for fluid transfer, understanding the various types of pumps available is crucial. One option that stands out for its reliability and efficiency is the positive displacement water pump. These pumps operate by trapping a fixed amount of water and then forcing it through the discharge pipe, making them ideal for applications requiring consistent flow rates, even against high pressure.

In the pursuit of the perfect positive displacement water pump, it's essential to consider several factors that will affect performance and suitability for specific applications. This guide aims to provide insights into how to evaluate your needs and the key characteristics of positive displacement water pumps, ensuring you make an informed decision. Whether you're looking for a pump for agricultural irrigation, industrial use, or residential water supply, understanding the intricacies of these pumps will help you choose the right model that meets your requirements effectively.

Understanding Positive Displacement Water Pumps: Types and Applications

Positive displacement water pumps are essential tools in various applications, including irrigation, wastewater management, and industrial processes. These pumps operate by trapping a fixed amount of water and forcing it out when the chamber is full, making them ideal for tasks requiring consistent flow and pressure.

There are several types of positive displacement pumps, such as gear pumps, diaphragm pumps, and piston pumps, each tailored to specific needs based on factors like fluid viscosity, flow rate, and discharge pressure.

Tips for choosing the right type of positive displacement pump include assessing the fluid characteristics and desired flow rate. For instance, gear pumps are excellent for low-viscosity fluids but may struggle with thicker substances. On the other hand, diaphragm pumps are well-suited for handling aggressive chemicals while providing excellent sealing. Additionally, consider the installation environment; a submersible pump might be necessary for applications involving water extraction from wells.

When selecting a water pump, it's crucial to evaluate the application requirements, including the need for portability or a compact design. Always calculate the total head and pressure requirements to ensure the pump can handle the demands of your system. By understanding the specific applications and types of positive displacement pumps available, you can make an informed decision that meets your needs effectively.

Key Factors in Selecting the Right Size for Your Water Pump

When selecting the right size for a positive displacement water pump, it is essential to consider several key factors that will directly impact the efficiency and functionality of the pump in your specific application. One of the primary considerations is the flow rate required by the system, typically measured in gallons per minute (GPM) or liters per second (L/s). According to the Hydraulic Institute, a standard flow rate should be carefully evaluated based on the system's demands to avoid oversizing or undersizing the pump, as this can lead to inefficiencies and increased operational costs.

Another critical factor is the total dynamic head (TDH), which represents the total height the water needs to be pumped. This includes both the vertical lift and any resistance encountered in pipes, fittings, and valves. Industry studies have shown that an accurate assessment of the TDH is vital for achieving optimal performance. For instance, ASHRAE’s guidelines indicate that a miscalculation here could lead to unnecessary energy consumption, with estimates suggesting that up to 20% of energy used in pump operations is due to incorrectly sized units.

Additionally, fluid characteristics such as viscosity and temperature can influence the selection process. The American Society of Mechanical Engineers highlights that understanding the properties of the fluid being pumped is crucial, especially when dealing with viscous liquids or those containing solids. Ensuring compatibility with the pump design can prevent wear and prolong service life, ultimately leading to better maintenance schedules and operational reliability. By carefully considering these factors, users can ensure they select the most appropriate positive displacement water pump to meet their needs efficiently.

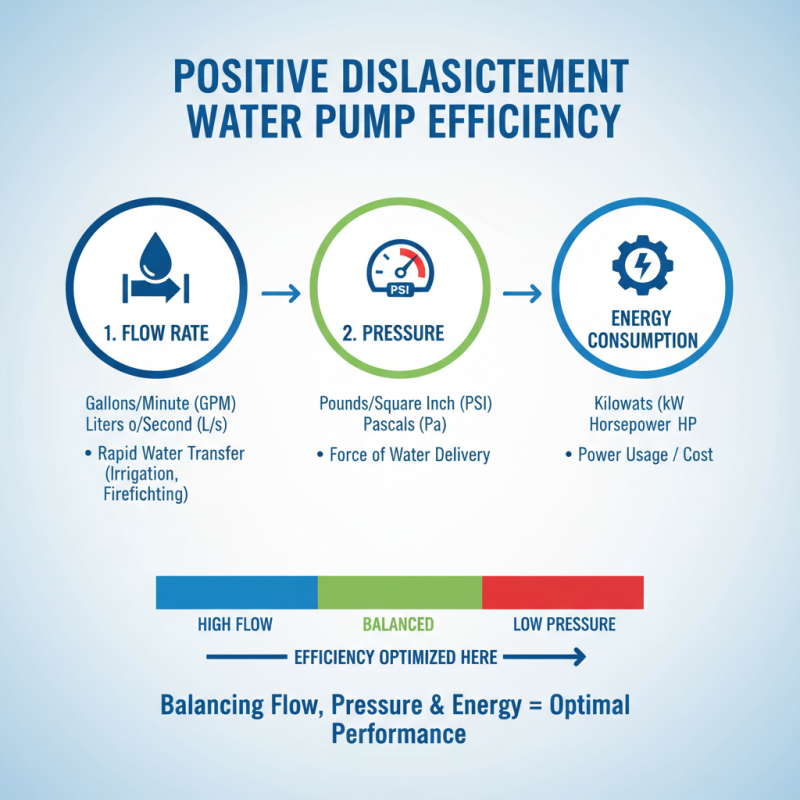

Evaluating Pump Efficiency: Flow Rate, Pressure, and Energy Consumption

When evaluating the efficiency of a positive displacement water pump, three key factors come into play: flow rate, pressure, and energy consumption. The flow rate, measured in gallons per minute (GPM) or liters per second (L/s), indicates how much water the pump can deliver over a specific time. A higher flow rate is beneficial for applications that require rapid water transfer, such as irrigation or firefighting. However, it is essential to balance flow rate with the pump's operational pressure, as excessive flow can lead to reduced pressure and inefficient performance.

Pressure, typically expressed in pounds per square inch (PSI) or bars, reflects the pump's ability to overcome resistance in the system. Understanding the required pressure for your specific application is crucial; if the pressure is too low, the pump may struggle to deliver water effectively, whereas excessive pressure can lead to energy wastage and potential equipment damage. Therefore, selecting a pump that meets the needed pressure without unnecessary over-specification is vital.

Lastly, energy consumption is a critical aspect to consider, particularly in terms of operational costs and environmental impact. A pump that operates efficiently will consume less energy, translating to lower electricity bills and a reduced carbon footprint. It is advisable to review the pump's performance curve to ensure that it operates within its optimal efficiency range for your applications, balancing flow rate and pressure while minimizing energy use. By carefully evaluating these components, one can choose a positive displacement water pump that best meets their operational needs.

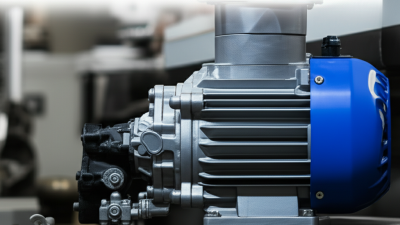

Material Considerations: Corrosion Resistance and Durability of Pumps

When selecting a positive displacement water pump, material considerations play a crucial role, particularly in terms of corrosion resistance and durability. According to a report by the Hydraulic Institute, about 50% of pump failures are attributed to material degradation due to environmental factors such as chemical exposure, vibration, and temperature fluctuations. Therefore, choosing the right material is essential to ensuring the longevity and performance of the pump in various operational conditions.

Stainless steel and thermoplastics are among the most commonly recommended materials for water pumps due to their superior resistance to corrosion. A study published in the Journal of Water Research highlights that stainless steel pumps can withstand harsh environments while maintaining their integrity over a longer operational lifespan compared to carbon steel counterparts. In contrast, thermoplastic pumps, such as those made from polypropylene, are particularly effective for applications involving corrosive fluids, showcasing a significant improvement in durability and reduced maintenance costs. Selecting materials that are specifically engineered for the application can lead to improved reliability and cost efficiency over time.

Common Industry Standards and Certifications for Water Pumps in 2025

When choosing a positive displacement water pump in 2025, understanding the common industry standards and certifications is crucial to ensure reliability and efficiency. The International Standard Organization (ISO) has established several standards, such as ISO 9906, which details hydraulic performance and ensures that pumps operate according to specified metrics. Compliance with ISO standards not only assures users of quality but also facilitates international trade, as many industries require such certifications for cross-border transactions.

Additionally, the American National Standards Institute (ANSI) provides guidelines that are widely recognized in North America. ANSI/HI 1.1 and ANSI/HI 3.1 specifically address the performance and testing of positive displacement pumps. These certifications help users to evaluate the suitability of the pump for different applications—ranging from agricultural irrigation to industrial processes—by providing metrics on efficiency, noise levels, and operating conditions. According to a recent market report by Technavio, compliance with these standards can enhance a pump’s marketability, increasing the product's value by approximately 15% due to the assurance of performance and safety (Technavio, 2023).

Ultimately, being informed about these standards and certifications not only aids in selecting the right positive displacement water pump but also enhances long-term operational reliability and maintenance efficiency. As industries gear towards sustainable practices, choosing certified pumps can contribute to reducing the environmental impact, aligning with the growing demand for eco-friendly equipment in various sectors.

Related Posts

-

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

Why You Should Choose Air Oil Pumps for Your Industrial Needs Today

-

10 Best Rotary Screw Pumps for Efficient Fluid Transfer in 2023

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China