How to Choose a Progressive Cavity Pump for Your Needs?

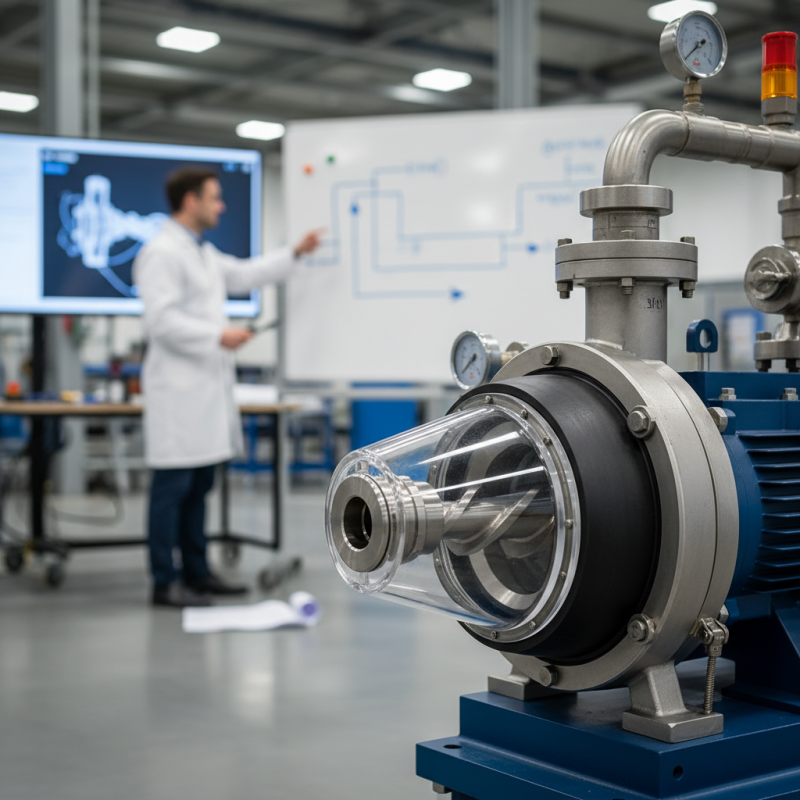

Choosing the right progressive cavity pump can be a daunting task. Experts like John Smith, a leading figure in pump technology, emphasize, “Understanding your specific needs is crucial.” The diversity of applications for progressive cavity pumps means features and functionality can vary greatly.

When selecting a pump, consider the fluid type, flow rate, and pressure requirements. For instance, does your application involve viscous fluids or slurries? These details are essential for making the best choice. However, many overlook their operating environment. Factors like temperature and space can significantly impact performance.

It's easy to feel overwhelmed with available options. Take time to reflect on your unique situation. A pump that works perfectly for one application may not suit another. Ask yourself: Are you prioritizing cost, efficiency, or durability? Each choice carries its own implications.

Understanding Progressive Cavity Pumps and Their Applications

Progressive cavity pumps are vital in numerous industries due to their unique design. They use a rotating screw to move fluids, making them suitable for handling viscous and abrasive materials. A report from the Global Pump Market indicates a 7% growth in demand for these pumps in wastewater management and food processing sectors.

In wastewater applications, these pumps can transport heavy sludge. They efficiently handle solids without clogging. Suitable selections can increase efficiency by up to 25%. However, not all pumps are fit for every need. It's essential to assess the viscosity and flow rate of the fluid. Miscalculations can lead to downtime and increased costs.

In the food industry, progressive cavity pumps are used for transferring sauces and dairy products. These pumps must adhere to strict sanitation standards. According to industry analysis, nearly 30% of food processors report challenges in maintaining hygiene. Detailed evaluations of pump material and sealing options are crucial in these applications. Choosing the wrong model can result in contamination risks that are hard to recover from.

Key Factors to Consider When Selecting a Progressive Cavity Pump

When selecting a progressive cavity pump, several key factors come into play. The fluid characteristics are crucial. You need to know the viscosity, temperature, and any solids present. These details influence pump material and design. A thick liquid requires a specific type of rotor and stator. They can handle varying viscosities but might struggle under extreme conditions. Likewise, temperature fluctuations can affect pump performance.

Consider flow rate and pressure requirements as well. Each application has its demands. A lower flow rate might work for some situations, while others need higher output. Balancing these factors is essential for efficiency. You might overlook the power source. Electric, hydraulic, or pneumatic options are available, each affecting installation and operation costs. Make sure you know what works best for your setup.

Maintenance needs can often be underestimated. Progressive cavity pumps require regular checks and occasional replacements. Missing details here can lead to costly downtimes. Understanding the total cost of ownership is important. Optimal performance relies on careful consideration of your specific needs, ensuring you're not left with a solution that falls short.

Evaluating Pump Specifications: Size, Capacity, and Materials

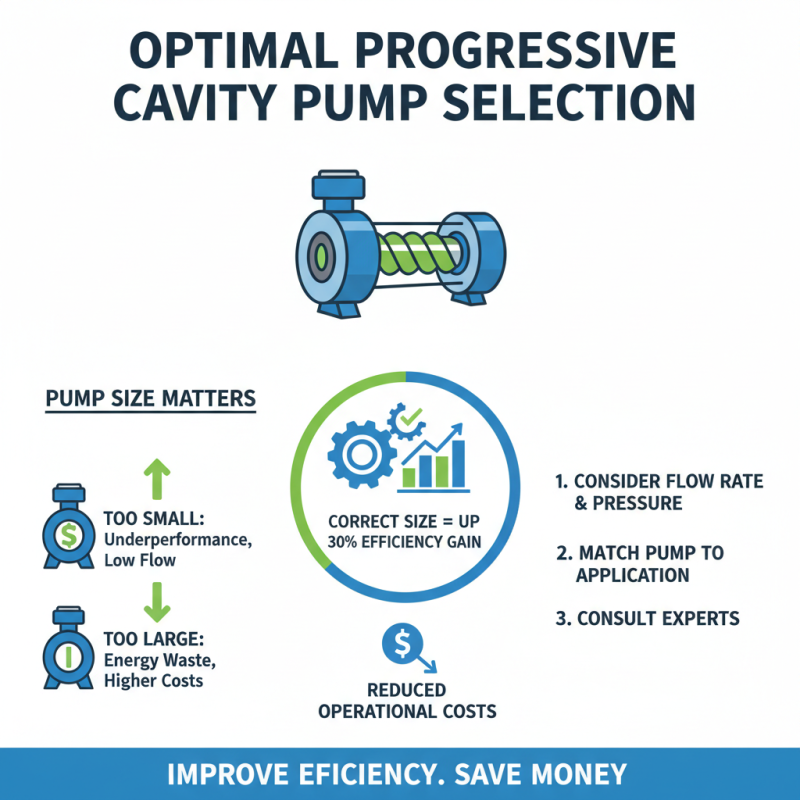

Choosing the right progressive cavity pump requires careful consideration of specifications. Size is critical. A pump too small may under-deliver, while one too large can waste energy. For example, industry studies indicate that a pump with the correct size can improve efficiency by up to 30%. This efficiency gains significantly affect operational costs.

Capacity is another vital factor. It's essential to match the pump’s capacity with your application needs. Common capacities range from 1 to 1000 gallons per minute. Selecting the wrong capacity can lead to operational problems. Materials are often overlooked. Pumps made of stainless steel or other corrosion-resistant materials last longer. Reports show that using high-quality materials can extend a pump's lifespan by 20-50%.

It’s easy to get overwhelmed by choices. Not all pumps work for every application. Consider the fluid's properties too. Viscosity, temperature, and chemical composition can affect pump performance. Some users find themselves needing to adjust their requirements mid-project, which is less than ideal. Assessing each specification carefully helps avoid costly mistakes.

Assessing Installation Requirements and Maintenance Needs

When selecting a progressive cavity pump, it’s crucial to assess installation requirements. Evaluate the available space in your facility. Make sure you measure clearly to determine how the pump will fit. Improper installation can lead to operational issues. Identify the surrounding environment, as this influences the pump’s positioning.

Maintenance needs are equally important. Regular checks can prevent unexpected breakdowns. Review the pump’s maintenance schedule and ensure accessibility for servicing. Consider the skill required for maintenance tasks. If the personnel lacks experience, training might be necessary.

Sometimes, even well-planned installations face unforeseen challenges. Unexpected vibrations or misalignments can arise. Addressing these issues promptly is key. Pay attention to performance metrics over time. This reflective practice can enhance long-term operation.

Exploring Manufacturer Reputation and Warranty Options

When choosing a progressive cavity pump, the manufacturer’s reputation is crucial. A strong reputation often indicates reliability and quality. Look for manufacturers with a long history in the industry. They are more likely to have the experience needed to produce durable pumps. Reviews and case studies can provide helpful insights into the manufacturer's performance.

Warranty options are equally important. A good warranty shows the manufacturer's confidence in their product. Look for warranties that cover a reasonable period. This can protect you against potential defects. Understand the terms closely. Some warranties may have exclusions that catch customers off guard.

Tips for assessing warranty options: Check for coverage details. Ensure it includes parts and labor. Ask about the warranty process. A simple process can save you time and frustration. Always ask for clarification if you find something unclear. Don't hesitate to reach out to customer service before making a commitment.

Comparison of Progressive Cavity Pump Features

Related Posts

-

How to Choose the Right Progressive Cavity Pump for Your Needs?

-

2025 Top 5 Lube Oil Systems: Enhance Engine Performance and Longevity

-

Top Twin Screw Pump Manufacturers in 2026 What Are They?

-

Revolutionizing Lube Oil Systems: The Future of Engine Performance and Efficiency

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

-

Top Lube Pump Types for Efficient Fluid Transfer Solutions?