How to Choose the Right Lube Oil Pump for Your Needs?

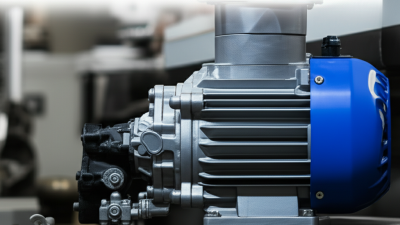

Choosing the right lube oil pump is crucial for machinery performance. A study by the American Society of Mechanical Engineers highlights that improper lubrication can lead to over 70% of machinery failures. Lube oil pumps are essential in maintaining optimal performance. They ensure that oil circulates effectively, reducing wear and tear.

When selecting a lube oil pump, consider factors like flow rate and pressure. Many industry professionals recommend pumps that can adapt to varying temperatures. This adaptability helps in avoiding pump failures. Data from the National Lubrication Conference indicates that poor selection can cost businesses significantly in downtime.

Yet, many users overlook crucial specifications. They often focus too much on price. Sometimes, functionality is compromised for a lower cost. It’s vital to reflect on long-term impacts. Regular maintenance can mitigate risks but starts with the correct pump choice. The right lube oil pump sustains equipment longevity, ultimately affecting overall productivity.

Understanding Different Types of Lube Oil Pumps and Their Functions

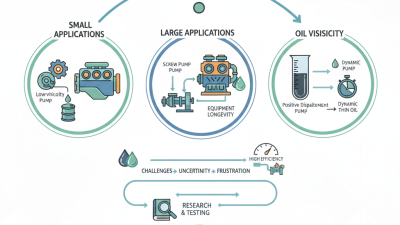

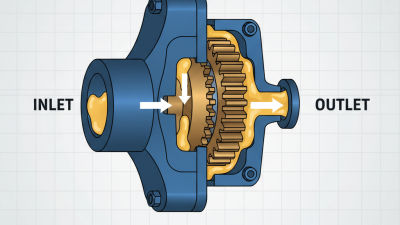

When choosing a lube oil pump, understanding the types available is crucial. Gear pumps are popular for their simplicity and durability. They provide a steady flow, making them suitable for many industrial applications. However, they can struggle with thin oils.

Another option is the diaphragm pump. These pumps excel with various fluids and are less prone to leaks. They are perfect for handling corrosive materials. If you have fluctuating fluid viscosities, consider a progressive cavity pump. These can handle changes smoothly but may require more maintenance.

**Tips:** Always evaluate the specific viscosity of your lube oil. Also, check the pump’s compatibility with your system. Overlooking any detail may lead to inefficiency. Keep in mind that not every pump is suitable for all operations. It's vital to assess your needs carefully. A wrong choice could result in more costs down the road.

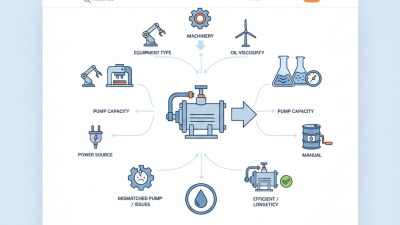

Factors to Consider When Selecting a Lube Oil Pump for Your Application

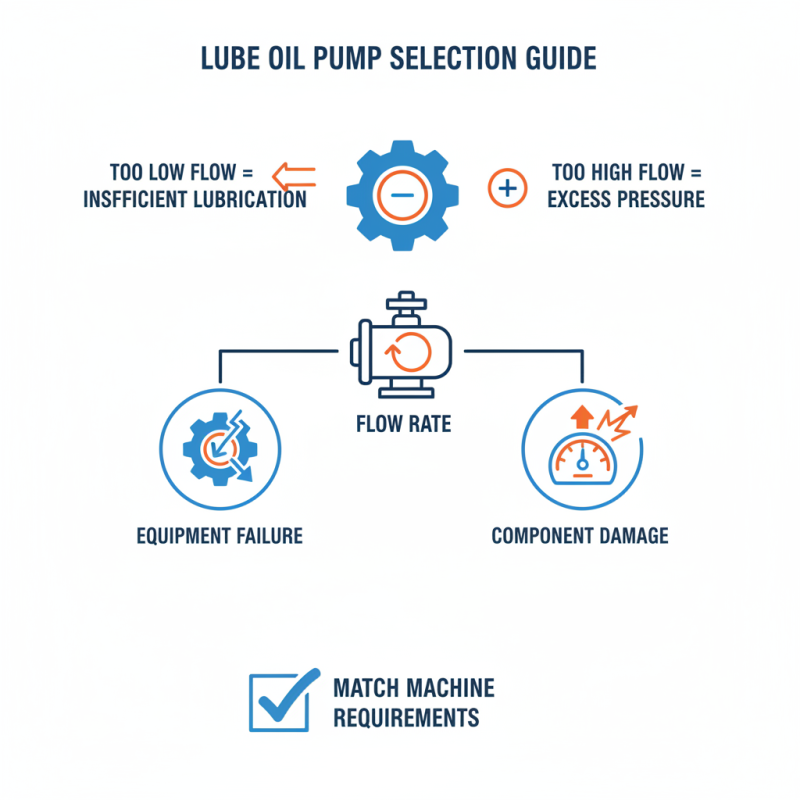

When selecting a lube oil pump, several factors come into play. Flow rate is crucial. It needs to match the machine's requirements. According to industry reports, a miscalculated flow rate can lead to equipment failure. Too low, and lubrication won't be sufficient. Too high, and it can create excess pressure, risking damage.

Viscosity compatibility is another important aspect. Different oils have varied viscosities. A pump designed for low-viscosity fluids may struggle with thicker oils. This mismatch could reduce efficiency. A study indicated that improper viscosity alignment could cut pump life by up to 30%.

Lastly, consider the environment in which the pump operates. Temperature fluctuations and exposure to contaminants can affect performance. Many pumps struggle in extreme conditions. Confined spaces may also limit installation options. Reassessing needs regularly helps adapt to changing applications. Always evaluate these factors to find a lube oil pump that truly meets your needs.

Assessing Pump Capacity and Flow Rate Requirements for Optimal Performance

Choosing the right lube oil pump involves understanding your specific needs. Pump capacity is crucial. It refers to how much fluid can be moved within a set time frame. Also, consider the flow rate. It's about the volume of oil the pump delivers. Too little flow can lead to underperformance. Too much can be wasteful and risky.

You might think a higher capacity is always better. But, it can lead to over-pressurization. This impacts your system negatively. Always measure your system’s requirements before finalizing a pump. Readjusting the size of the pump later can be challenging and often costly.

Many factors influence performance. Pipe size, viscosity of the oil, and ambient temperature all play a role. Again, these details are often overlooked. Failing to consider them can result in inefficient operation. It is necessary to repeatedly analyze and reflect on your choices in this process. Getting it right the first time may not always happen. But refining your selection will lead to better outcomes in the long run.

Evaluating Material Compatibility and Durability in Lube Oil Pumps

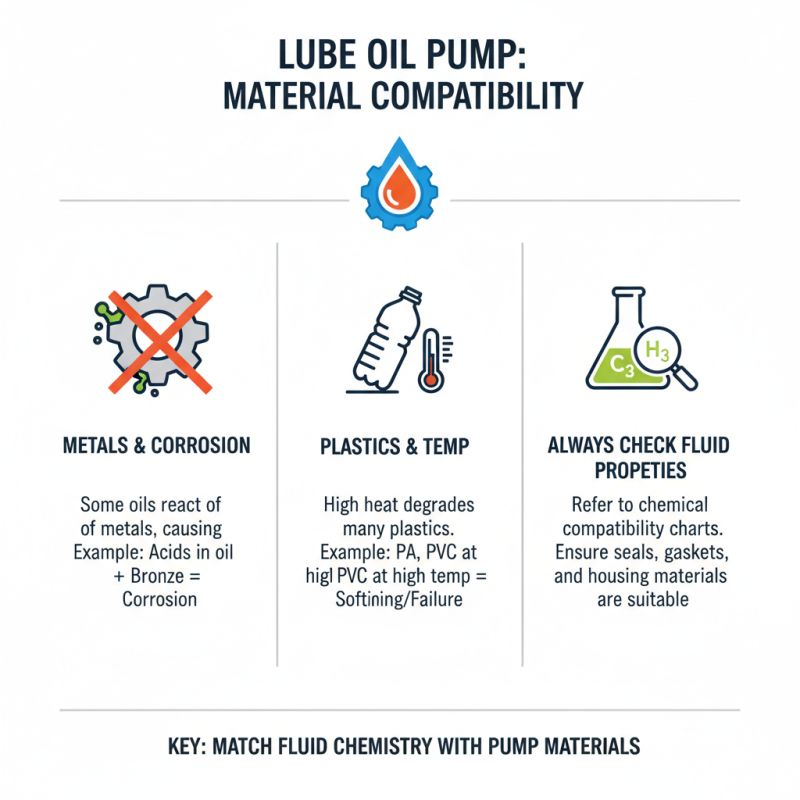

When selecting a lube oil pump, understanding material compatibility is crucial. Different oils and lubricants interact uniquely with various materials. For example, some metals corrode quickly in certain environments. Plastic components may not handle high temperatures well. Always check the chemical properties of the fluids you’ll be using.

Durability is another key factor. Pumps exposed to harsh conditions face wear and tear. Look for pumps with features that enhance longevity. This might include reinforced casings or specialized seals. However, even the best materials can fail. Regular maintenance is vital to ensure optimal function. This often requires a solid understanding of the pump’s construction.

Reflecting on your choices is essential. Don’t just focus on specifications. Consider previous failures or successes with different materials in your operations. Learning from past experiences encourages better decision-making. Choosing the right material can be the difference between a robust pump and constant rework. Always remain proactive in evaluating your pump’s performance over time.

The Importance of Maintenance and Support for Long-Term Pump Reliability

Maintenance and support are critical for the long-term reliability of lube oil pumps. According to a report by the International Pump Manufacturers Association, 30% of pump failures result from poor maintenance practices. Simple routine checks can drastically reduce this risk. For instance, monitoring oil viscosity can prevent damage from operating under unsuitable conditions.

Regular maintenance extends the lifespan of pumps, as highlighted by a study from the Hydraulic Institute showing that well-maintained pumps can last up to 50% longer. Neglecting maintenance can lead to unexpected failures, which are costly. This scenario not only disrupts operations but also increases operational expenses.

Support plays a significant role in ensuring durability. Having access to expert guidance can make a difference. Training staff on proper usage can minimize errors during operation. However, many companies often underestimate this aspect. A surprising 40% lack a structured training program for new employees. This gap can lead to misuse and increased wear on equipment.

Proper maintenance and support should not be afterthoughts; they are essential for optimal pump performance.

Related Posts

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

-

Best Lube Oil Pump Types for Your Needs?

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

How to Choose the Right Oil Lubrication Pump for Your Needs