How to Choose the Right Lube Pump for Your Needs?

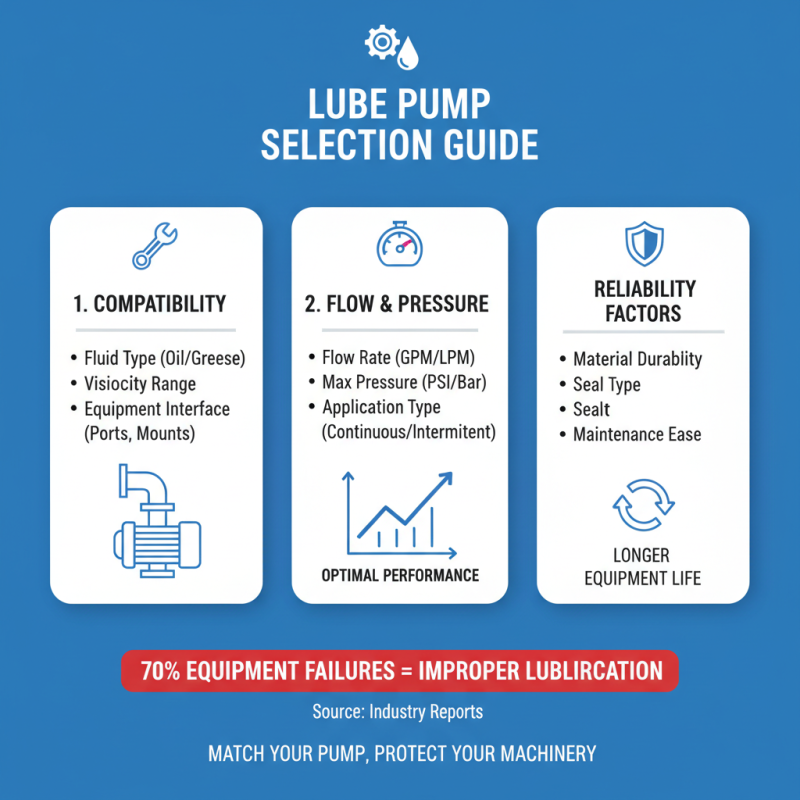

Choosing the right lube pump is crucial for operational efficiency. An estimated 70% of industrial machinery failures result from inadequate lubrication. This highlights the significance of selecting an appropriate lube pump to maintain machinery health. With various options available, the challenge lies in identifying the best fit for specific applications.

Different industries may require unique specifications for their lube pump. For instance, a pump designed for automotive applications may not suffice for heavy machinery. Failing to understand the specific needs can lead to inefficiencies. According to industry reports, using the wrong pump can increase maintenance costs by up to 40%. This reality emphasizes the need for careful consideration before purchasing a lube pump.

Additionally, there are factors like viscosity and operating conditions to consider. A pump that works well in a stable environment might underperform in a fluctuating one. Users often overlook these details, affecting their long-term satisfaction. Reflecting on these aspects can lead to better decisions. Ultimately, the goal is to find a lube pump that not only meets immediate needs but also contributes to overall operational success.

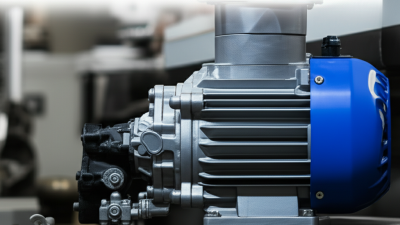

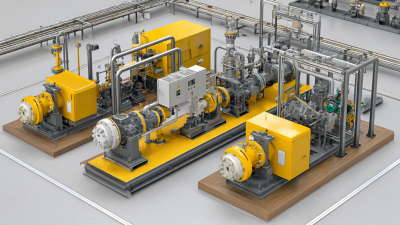

Understanding Different Types of Lube Pumps Available in the Market

When considering the right lube pump, understanding the different types available is vital. Gear pumps are one popular option. They work by using meshing gears to move lubricant. These pumps offer precise flow rates and are durable. However, they may require regular maintenance to prevent wear.

Diaphragm pumps are another choice. They use a diaphragm to create suction and discharge. This type is great for handling various fluids. They can manage aggressive lubricants effectively. Still, they are not always the most efficient compared to others.

Piston pumps provide high pressure and flow. They are excellent for heavy-duty applications. Yet, they may be more complex to install. Local conditions can affect performance. Always assess your specific needs before making a decision. Consider factors like the viscosity of the lubricant, application, and required flow rate. Doing so ensures you select the best option tailored to your requirements.

Types of Lube Pumps

This chart illustrates the percentage of usage for different types of lube pumps available in the market. The data helps in understanding which pump types are more prevalent based on user needs.

Key Factors to Consider When Choosing a Lube Pump

When selecting a lube pump, various factors should be evaluated. One key aspect is the viscosity of the lubricant. Reports suggest that over 70% of lubrication failures happen due to incorrect viscosity selection. Thicker lubricants require more robust pumps. In contrast, lighter oils can be managed with simpler systems. Understanding your lubricant's properties helps ensure the pump performs efficiently.

Compatibility is another crucial element. Not every pump works with every lubricant. For example, a pump designed for oil might not handle greases effectively. Industry data shows that 30% of equipment failures are attributed to inappropriate lubrication. Therefore, it's wise to consult compatibility charts. Confirming compatibility can save significant future costs.

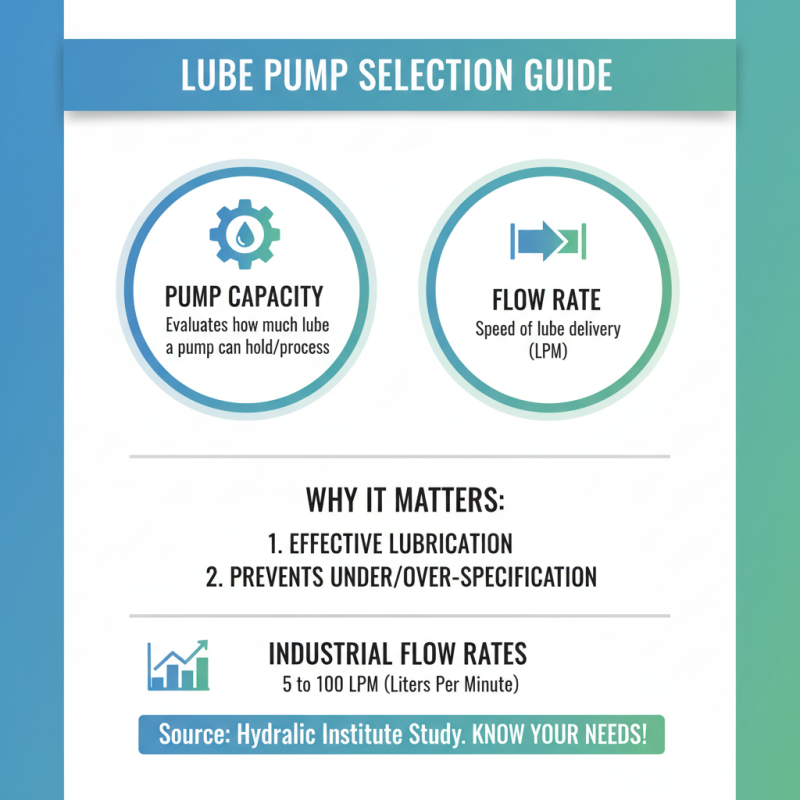

Pump capacity is vital as well. Consider the machinery’s demands. Under or over-specifying can lead to issues. Many operators underestimate their needs, which may result in costly downtime. Reports indicate that up to 40% of lube pump malfunctions stem from incorrect capacity selection. It's essential to analyze the operational environment and lubrication frequency before making a decision.

These reflections will guide you in finding a pump that meets your particular requirements.

Assessing the Compatibility of Lube Pumps with Your Equipment

Choosing the right lube pump requires careful consideration of compatibility with your equipment. Research from industry reports indicates that over 70% of equipment failures are linked to improper lubrication. Identifying the pump that matches your machinery’s specifications is essential.

Compatibility involves assessing the viscosity and flow rate of the lubricant. Many manufacturers recommend pumps that can handle a specific range. A misalignment could lead to inefficiencies or damage over time. Furthermore, monitoring pump temperature and pressure is crucial. According to a recent study, pumps that exceed recommended temperatures have a 40% shorter lifespan.

Always evaluate your equipment’s requirements. This includes checking the pump’s material and design. Some pumps may corrode with certain lubes. Incompatibility may result in production delays and costly repairs. Insufficient data often leads to poor selections. This emphasizes the need to validate information before making a purchase.

Evaluating Pump Capacity and Flow Rate Requirements

When selecting a lube pump, it's essential to evaluate pump capacity and flow rate requirements. These factors dictate how effectively a pump can deliver lubrication. According to a study by the Hydraulic Institute, flow rates can vary significantly between different applications. For example, industrial systems may require a flow rate of 5 to 100 liters per minute. Understanding your specific needs will help prevent underperformance or over-specification.

Run a simple test to gauge your flow requirements. Measure the total volume of lubricant needed for your applications. Break it down by regions or components that require lubrication. Calculate the time you have available to achieve this. If you need 50 liters in 10 minutes, your flow rate must be at least 5 liters per minute.

Tips: Consider a pump with adjustable capacity. This flexibility lets you adapt to changing demands. Oversizing a pump can lead to wasted energy and higher costs. Smaller pumps can deliver precise amounts but may not meet peak demand efficiently. It's crucial to find balance and optimize your choice.

Maintenance and Longevity Considerations for Lube Pumps

When it comes to lube pumps, maintenance plays a crucial role in ensuring longevity. Regular checks can prevent minor issues from escalating. Routine inspections should include checking for leaks, wear, and tear. Noticing a small drip can save hundreds in repairs.

Cleanliness is vital. Dust and debris can compromise a pump’s efficiency. Ensure the area around the pump is free from contaminants. Depending on the environment, maintenance intervals may vary. Sometimes, it’s easy to overlook the little things that can lead to big problems.

Consider lubrication quality as well. Subpar lubricants can damage your pump over time. The right lubricant ensures smooth operation. Don’t forget user guidelines for pump upkeep. They often provide unique insights specific to your model. Regular training for staff can also improve maintenance awareness.

How to Choose the Right Lube Pump for Your Needs?

| Pump Type | Flow Rate (L/min) | Lubricant Type | Power Source | Maintenance Frequency | Estimated Lifespan (Years) |

|---|---|---|---|---|---|

| Electric Gear Pump | 10 | Oil | Electric | Monthly | 5 |

| Pneumatic Diaphragm Pump | 5 | Grease | Pneumatic | Quarterly | 3 |

| Manual Lever Pump | 2 | Oil | Manual | As Needed | 10 |

| Electric Vane Pump | 15 | Oil | Electric | Bi-Annually | 7 |

Related Posts

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

How to Choose the Right Progressive Cavity Pump for Your Needs?

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

-

Top 10 Benefits of Using an Asphalt Pump for Your Projects?

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

2025 Top 10 Displacement Pumps: Market Trends & Key Performance Insights