How to Choose the Right Oil Lubrication Pump for Your Needs

Choosing the right oil lubrication pump can be challenging. Various factors must be considered. The oil lubrication pump you select should meet specific requirements for your machinery.

Consider the type of equipment you have. Different applications require different pumps. Think about the viscosity of the oil. This detail affects pump performance. A mismatched pump might cause operational issues. Efficiency is crucial here. You want a pump that works well under pressure.

Also, consider the pump's capacity. A pump that is too small won't keep up. Conversely, an oversized pump may waste resources. Evaluate the total volume of oil needed. Don't ignore power sources either. Some pumps require electrical power while others may operate manually. Reflect on these details. Picking the right oil lubrication pump is a process. Be thorough, as your choice impacts equipment longevity.

Understanding the Basics of Oil Lubrication Pumps

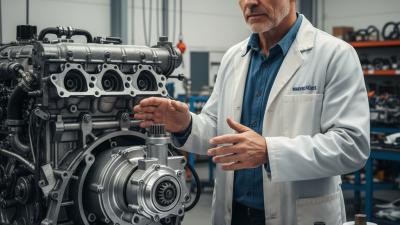

When selecting an oil lubrication pump, understanding the basics is key. Oil pumps are essential for machinery that requires a constant supply of oil. They reduce friction and wear. This enhances efficiency and longevity.

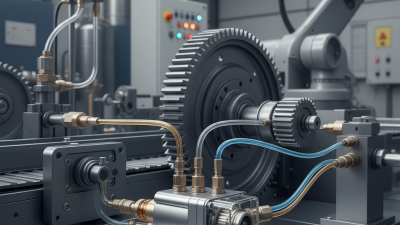

Consider the pump type. There are gear pumps, diaphragm pumps, and piston pumps. Each type serves different applications. Gear pumps are common for high flow rates. Diaphragm pumps are great for precise oil delivery. Piston pumps excel in high-pressure situations.

**Tips:** Choose based on your machinery’s needs. Assess the viscosity of the oil. Oil thickness greatly influences pump performance. A pump that works well at one viscosity might fail at another. Also, consider maintenance requirements. Some pumps need frequent servicing, while others are more robust and durable.

Identifying Your Specific Lubrication Requirements

When selecting the right oil lubrication pump, understanding your specific lubrication requirements is key. Start by assessing the type of machinery you have. Different equipment has varying needs in terms of oil viscosity, volume, and delivery pressure. Consider the operating temperature as well. If your machinery runs hot, you'll need a pump that can handle higher temperatures efficiently.

Next, evaluate the working environment. Factors like dust, humidity, and space constraints can influence your choice. A small, compact pump may fit better in tight spaces, while a robust system might be necessary for harsh conditions. Don’t forget about maintenance. Some pumps require more upkeep than others, which might not be feasible for every setting.

Think about the long term. Will your lubrication needs change as your operations grow? Choosing a flexible pump that can adapt is wise. Test different options before finalizing your selection. Sometimes, what seems ideal on paper may not perform well in practice. Reflect on your experiences and adjust your choices accordingly. This process requires patience and thorough consideration.

How to Choose the Right Oil Lubrication Pump for Your Needs

This chart illustrates the various types of oil lubrication pumps based on their flow rate requirements, which can help in identifying the most suitable pump for specific lubrication needs.

Evaluating Different Types of Oil Lubrication Pumps

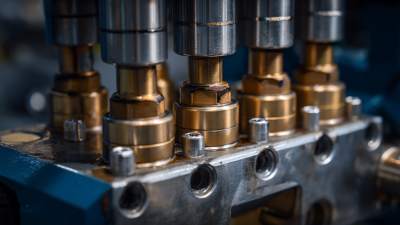

When evaluating different types of oil lubrication pumps, it’s essential to understand their functionalities and applications. For instance, gear pumps are commonly used for high viscosity oils. They provide consistent flow and durability. However, they may not be ideal for low viscosity applications. Reports suggest that about 40% of machinery failures result from inadequate lubrication. This statistic highlights the importance of selecting the right pump.

Another option is diaphragm pumps. These are known for handling various liquids and fluids. Their ability to work with corrosive materials makes them versatile. However, their flow rates can be slower than other pumps. Research indicates that almost 30% of industrial processes utilize diaphragm pumps. Despite their benefits, choosing them might require some reflection on your specific needs.

Finally, consider progressive cavity pumps. They excel in maintaining a steady flow rate. But they can be more complex to maintain compared to gear or diaphragm pumps. Industry data shows that approximately 25% of companies report difficulties in maintaining these pumps. Finding the right balance between efficiency and ease of use is crucial.

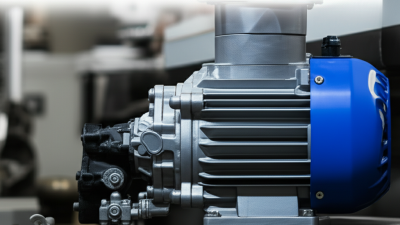

Key Features to Consider When Choosing a Pump

Choosing the right oil lubrication pump can be a daunting task. There are many factors to consider. Key features include pump type, flow rate, and temperature range. A report from the Hydraulic Institute suggests that flow rates can significantly impact efficiency. For example, pumps with a flow rate under 10 GPM can often meet small-scale operations effectively.

Another important aspect is the temperature range. A well-designed pump should handle temperatures from -20°F to over 300°F. Many industries report failures when pumps operate outside recommended temperatures. Data shows that over 30% of oil pump failures are due to improper temperature settings. This emphasizes the importance of selecting a pump that can withstand extreme conditions.

Moreover, consider the pump's material. This affects durability and compatibility with various oils. A material mismatch can lead to leaks and pump breakdowns. Yet, many users overlook this detail, which can be critical. Survey results indicate that 45% of users experience operational issues due to material concerns. Understanding these key features will help you make a more informed decision.

Maintaining and Servicing Your Oil Lubrication Pump

Maintaining and servicing your oil lubrication pump is crucial for optimal performance. Research shows that proper maintenance can extend the lifespan of these pumps by 20-30%. Regular checks of the pump's operating temperature and vibration levels can help prevent unexpected failures. For instance, a temperature rise of just 10°C can reduce the pump’s efficiency significantly.

Scheduled service intervals play a vital role. Many facilities overlook this aspect. In fact, up to 40% of lubrication system failures are due to poor maintenance practices. Regularly changing filters and replenishing lubricants can minimize wear and tear. It's better to replace a small part than to face major repairs later.

Documentation should be meticulous. Tracking maintenance schedules and performance metrics helps identify issues early. Industry standards recommend reviewing pump performance every 500 hours of operation or every three months. This habit ensures proactive rather than reactive management. Neglecting these practices often leads to added expense and downtime. Continuous improvement in maintenance strategies is necessary for every operation.

Related Posts

-

How to Choose the Right Lubrication Pump for Your Needs

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

-

Essential Guide to Optimal Pump Lubrication: Enhance Efficiency and Longevity