How to Choose the Right Progressive Cavity Pump for Your Needs?

Choosing the right progressive cavity pump can be daunting. Experts like John Smith, a leader in pump technology, often say, "A right fit maximizes performance." With various options available, understanding specific needs is crucial.

Progressive cavity pumps are widely used. They excel in handling thick sludge, chemicals, and other viscous materials. However, selecting the wrong model can lead to inefficiencies. For instance, overestimating flow requirements can strain the system. This results in energy loss and potential equipment damage.

Every application varies. Consider factors like viscosity, flow rate, and pressure. Misjudging any of these can compromise performance. It's essential to consult industry experts and assess operations before making a choice. A thoughtful approach leads to better outcomes in the long run.

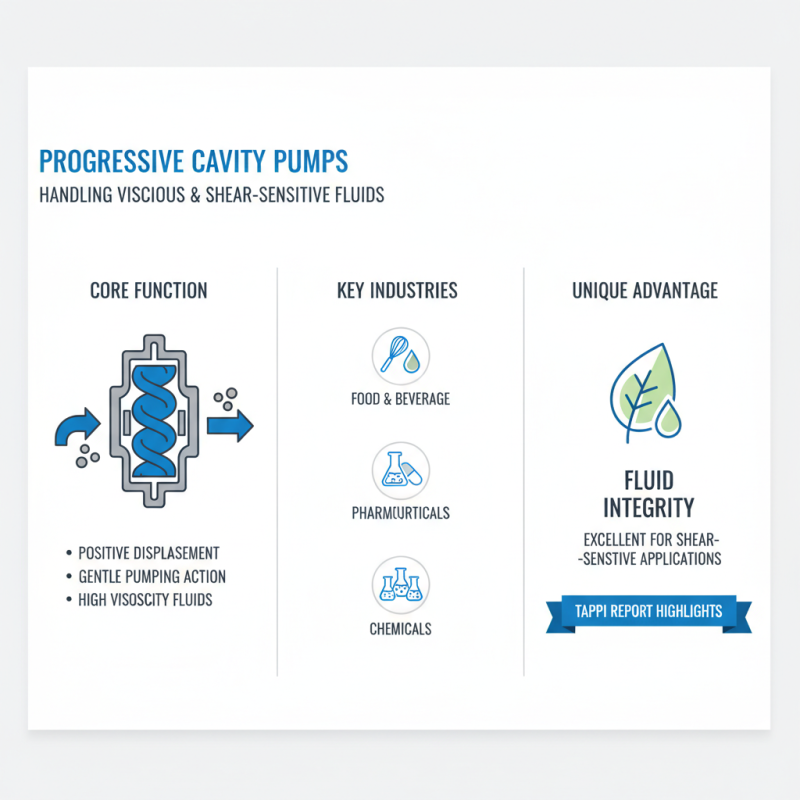

Understanding the Basics of Progressive Cavity Pumps

Progressive cavity pumps are essential in various industries. They are designed to handle viscous fluids effectively. Common applications include food, pharmaceuticals, and chemicals. A report by the Technical Association of the Pulp & Paper Industry indicates that these pumps excel in shear-sensitive applications. This quality makes them valuable where fluid integrity is crucial.

Understanding their mechanics is vital. A progressive cavity pump uses a helical rotor and a stator to create a cavity that moves fluid steadily. This design minimizes turbulence, preserving the product's quality during transfer. According to a market research survey, nearly 40% of users express challenges in selecting the correct pump type. Factors like fluid viscosity, temperature, and required flow rate significantly affect performance.

Choosing the right pump isn't straightforward. Many users overlook factors such as maintenance needs and operational costs. A report from the Pumps & Systems Journal highlights that improper selection can lead to increased downtime and repair costs. It's critical to analyze specific requirements before making a decision. Ensure the pump aligns with both the application and the environment in which it will operate.

Identifying Your Application Requirements and Fluid Characteristics

Choosing the right progressive cavity pump starts with understanding your application requirements and fluid characteristics. Every application is unique. The fluid's viscosity, temperature, and solids content significantly impact the pump's performance. For example, fluids with a viscosity greater than 1,000 cP can put strain on the pump.

Industry data shows that 70% of pump failures are linked to improper applications. It's crucial to assess the nature of the fluid. Is it clean, or does it contain abrasive solids? For a slurry, you may need a pump designed for challenging environments. In comparison, a low-viscosity fluid might require a different configuration.

Always consider the fluid's temperature as well. A pump operating near its maximum temperature rating can accelerate wear and lead to failures. Reflect on these aspects - missing details can result in costly downtime. Essential data, like fluid behavior under varying pressures, should not be overlooked. Proper analysis ensures efficiency and longevity in pump operations.

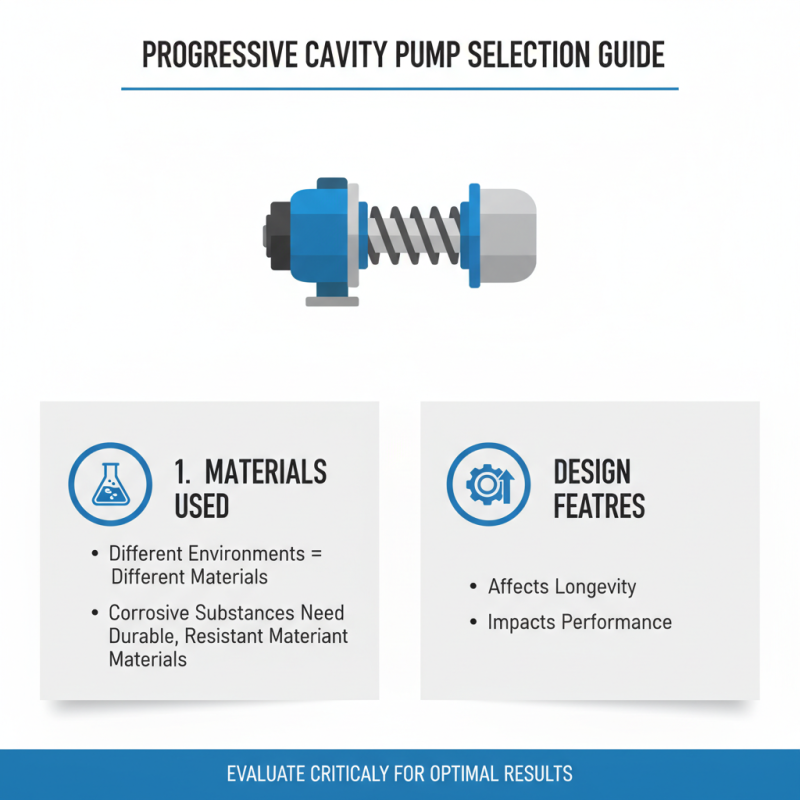

Evaluating Pump Design Features and Performance Metrics

When selecting a progressive cavity pump, evaluating design features is critical. Start by examining the materials used. Different environments require different materials. For instance, corrosive substances need durable, resistant materials. This can affect longevity and performance.

Next, consider the pump’s performance metrics. Flow rate is vital for understanding how much liquid can be moved. Efficiency is important as well. A more efficient pump saves energy and reduces costs over time. However, finding a balance between efficiency and power can be challenging.

Also, think about maintenance requirements. Some pumps require regular service, which can increase operational costs. Not every design is easy to maintain. Reflect on your team’s capabilities and resources. This can influence your choice significantly. Complications may arise from overlooking these aspects. Take the time to weigh the options carefully.

Comparing Manufacturer Options and Support Services

When selecting a progressive cavity pump, it’s essential to consider not only the technical specifications but also the manufacturer’s support services. Recent industry reports show that 78% of companies prioritize ongoing support when choosing equipment. This is because a reliable support system can significantly reduce downtime and maintenance costs.

Different manufacturers offer varying levels of service. Some may provide 24/7 customer support, while others may limit their availability. It’s worth noting that 65% of users report experiencing challenges due to inadequate support after purchase. Investigating the warranty, replacement parts availability, and training resources is crucial. Without proper training, operators might struggle, leading to inefficiencies.

Lastly, consider user feedback on service experiences. Many users have highlighted the importance of timely troubleshooting. When a pump malfunctions, every hour counts. One case study revealed that companies facing delays in service requests reported a 30% increase in operational costs. While pump performance is vital, the manufacturer's support can make or break your operational success.

How to Choose the Right Progressive Cavity Pump for Your Needs?

| Manufacturer | Pump Performance | Support Services | Warranty Period | Customization Options |

|---|---|---|---|---|

| Manufacturer A | Up to 500 GPM | 24/7 support | 3 years | Yes |

| Manufacturer B | Up to 600 GPM | Business hours support | 2 years | Limited |

| Manufacturer C | Up to 700 GPM | Online support | 5 years | Extensive |

| Manufacturer D | Up to 400 GPM | Limited hours support | 1 year | No |

Analyzing Cost Considerations and Long-term Maintenance Needs

When selecting a progressive cavity pump, cost considerations play a vital role. The initial purchase price can be enticing, but hidden costs often arise. Maintenance is one of those factors that can significantly impact overall expenses. Choosing a unit that does not require frequent upkeep can save money over time.

Tips: Always review maintenance documentation. Understand what parts may wear out quickly. This can prevent unexpected repairs.

Long-term maintenance needs vary by application. Some pumps may operate in harsh environments. This can lead to quicker degradation and higher replacement costs. Regular maintenance checks can identify issues early. Neglecting these checks might lead to bigger expenses later.

Tips: Schedule routine inspection intervals. Keeping a log of maintenance activities is beneficial. Look for signs of wear on components frequently.

Investing in the right pump is essential, but understanding long-term costs is crucial. While a cheaper pump might fit your budget now, think about the future. A more durable option could ultimately save you time and money in repairs and replacements. Reflecting on your specific needs will guide you in making an informed choice.

Cost Comparison of Progressive Cavity Pumps

Related Posts

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

Top 2025 Rotary Screw Pump Innovations: What You Need to Know

-

2025 Top 5 Lube Oil Systems: Enhance Engine Performance and Longevity

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

-

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

-

Understanding the Impact of Oil Lubrication Pumps on Equipment Longevity: Key Insights and Data