Top Benefits of Double Screw Pumps for Efficient Fluid Handling

The growing demand for efficient fluid handling solutions across various industries has led to the increasing adoption of advanced pumping technologies. Among these, the double screw pump stands out due to its unique design and operational advantages. According to a recent market analysis report by XYZ Research, the global pump market is projected to reach USD 70 billion by 2025, with double screw pumps gaining traction for their superior performance in handling viscous fluids and shear-sensitive materials. This surge is largely attributed to their high efficiency, durability, and ability to operate with minimal pulsation, making them ideal for applications in sectors such as oil and gas, chemical processing, and food and beverage.

Furthermore, recent studies indicate that double screw pumps can reduce energy consumption by up to 30% compared to traditional pumping systems, resulting in significant cost savings for operators. This efficiency is particularly crucial in an era of increasing energy prices and a growing emphasis on sustainability. As industries strive to enhance their operational efficiency while minimizing environmental impact, the merits of double screw pumps continue to be recognized, positioning them as a valuable asset in modern fluid handling applications. With advancements in technology and design, double screw pumps are expected to play an even more prominent role in addressing the challenges of fluid management in the years to come.

Advantages of Double Screw Pumps in High-Viscosity Fluid Transfer

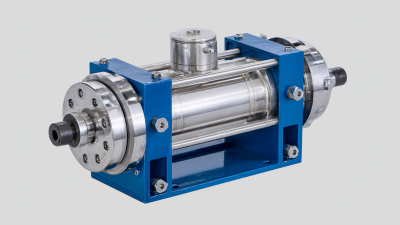

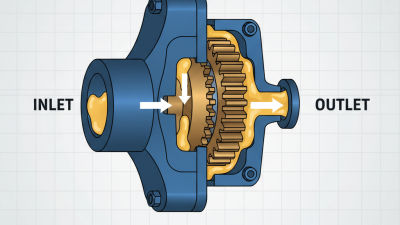

Double screw pumps are particularly advantageous for transferring high-viscosity fluids, thanks to their unique design and operational characteristics. The ability to handle thick, sticky fluids without compromising performance is one of the standout features of this pump type. As the double screws rotate in opposite directions, they create a self-priming action that minimizes cavitation, making them ideal for moving viscous materials that would typically bog down other pump types. This ensures a steady flow rate, even under varying ambient conditions, thereby enhancing overall efficiency in fluid handling processes.

Another significant advantage of double screw pumps is their capacity for gentle fluid transfer. The design allows for a low shear environment, which is crucial when managing sensitive or shear-sensitive fluids. Many high-viscosity applications, such as those involving food, cosmetics, or pharmaceuticals, benefit from this gentle handling, as it preserves the integrity of the conveyed materials. This not only improves product quality but also reduces the risk of damage during transfer, ensuring that the fluid maintains its desired properties throughout the process.

Energy Efficiency: Reduced Power Consumption in Double Screw Pump Operation

Double screw pumps are increasingly recognized for their energy-efficient performance in fluid handling operations. One of the most significant benefits is their reduced power consumption, making them an ideal choice for industries seeking to lower operational costs while maintaining high efficiency. Unlike conventional pumps that may waste energy through turbulence and inefficiency, double screw pumps employ a unique design that minimizes friction and optimizes flow patterns. This leads to a marked decrease in the energy required to move fluids, translating to lower energy bills and a reduced carbon footprint.

When considering the implementation of a double screw pump in fluid handling systems, it is essential to evaluate your specific application needs carefully. **Tip:** Conduct a thorough analysis of your fluid properties and flow requirements to select the right pump configuration that maximizes efficiency and minimizes energy usage. Regular maintenance can also play a crucial role in sustaining energy efficiency. **Tip:** Schedule periodic inspections and maintenance checks to ensure that your pump operates at its best, as even minor inefficiencies can lead to increased power consumption over time.

Additionally, double screw pumps excel in scenarios requiring variable flow rates, ensuring that energy consumption adapts based on operational demands. This flexibility can significantly reduce wasted energy during periods of lower demand. **Tip:** Monitor your system's performance and adjust pump settings accordingly to optimize energy usage, especially during fluctuating operational patterns. Embracing double screw pump technology not only enhances fluid handling efficiency but also fosters environmentally responsible practices through its focus on energy conservation.

Energy Efficiency: Power Consumption in Double Screw Pumps

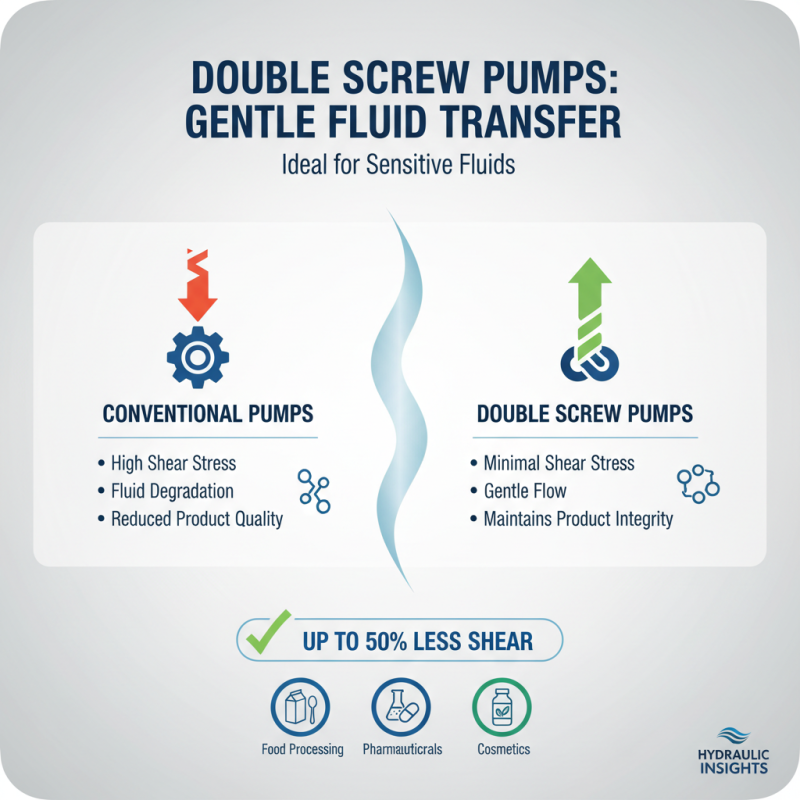

Minimized Shear Stress: Benefits for Sensitive Fluid Handling Applications

Double screw pumps are increasingly recognized for their ability to handle sensitive fluids with minimal shear stress, making them ideal for a variety of applications in industries such as food processing, pharmaceuticals, and cosmetics. The design of double screw pumps allows for a gentle flow, reducing turbulence and ensuring that delicate substances retain their integrity. According to a report by the Hydraulic Institute, the shear stress created by conventional pumps can lead to the degradation of sensitive fluids, which can significantly impact product quality and consistency. In contrast, double screw pumps can decrease shear rates by up to 50%, making them a preferred choice for applications where maintaining the molecular structure of the fluid is critical.

When working with sensitive fluids, it's essential to select the right pump to minimize damage during handling. Industry experts recommend conducting a hydraulic analysis to determine the appropriate pump specifications based on the fluid’s viscosity and shear sensitivity. Also, consider the operational parameters; for instance, maintaining a consistent flow rate can help limit shear stress, ensuring that the fluid moves smoothly through the pipeline. Overall, understanding the properties of the fluids being handled and choosing the right pump technology can lead to improved product quality and operational efficiency.

Tip: Regular maintenance of double screw pumps can enhance their performance in sensitive applications. Ensure that all seals and connections are intact to prevent leaks, which can compromise pump efficiency and fluid integrity.

Durability and Longevity: Comparing Maintenance Costs of Pump Types

When it comes to selecting pumps for efficient fluid handling, one of the most significant considerations is maintenance costs, particularly when comparing various pump types. Double screw pumps are renowned for their durability and longevity, leading to lower overall maintenance expenses in the long run. According to a report by the Hydraulic Institute, double screw pumps can achieve a lifespan of up to 20 years with minimal maintenance, contrasted with traditional centrifugal pumps, which may require more frequent interventions and replacements. This longevity not only contributes to reduced labor costs associated with maintenance but also minimizes production downtime, which can be costly for businesses.

Tips for maintaining your pumps include conducting regular inspections to catch any potential issues early and adhering to the manufacturer's recommended maintenance schedule. Additionally, investing in training your staff on proper operation can prevent misuse and extend the life of your equipment significantly. A study from the American Society of Mechanical Engineers indicates that well-maintained pumps can operate at up to 95% efficiency, further emphasizing the importance of proactive maintenance practices.

In terms of cost-effectiveness, opting for double screw pumps can lead to substantial savings. Research from the Fluid Handling Association highlights that, while the initial investment may be higher, the aggregate maintenance costs for double screw pumps can be up to 40% lower over a decade compared to other types. This significant reduction in maintenance expenses, along with the reliability of these pumps, makes them an excellent choice for industries that demand high efficiency and long-term performance.

Versatility Across Industries: Applications of Double Screw Pumps in Various Sectors

Double screw pumps are becoming increasingly popular across a multitude of industries due to their unique design and operational versatility. In the oil and gas sector, these pumps play a vital role in the transportation of crude oil and other viscous fluids. Their ability to handle a wide range of fluid viscosities ensures efficient operation even in challenging environments. Additionally, double screw pumps are utilized in water treatment facilities, where they facilitate the transfer of sludge and other thick materials, promoting effective waste management and environmental sustainability.

In the food and beverage industry, double screw pumps are recognized for their hygienic operation and ability to manage delicate products without compromising quality. They efficiently transport fluids like syrups, sausages, and dairy products while minimizing shear and maintaining product integrity. Moreover, their reliable performance in chemical processing applications allows for the safe and effective handling of various reactive and viscous chemicals, further underscoring their versatility. The adaptability of double screw pumps makes them a critical component in numerous sectors, contributing significantly to improved operational efficiency and the seamless handling of diverse fluids.

Related Posts

-

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

-

10 Best Rotary Screw Pumps for Efficient Fluid Transfer in 2023

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

Top 5 Positive Displacement Pump Manufacturers You Should Know About

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems