Top 10 Essential Pumps for Oil: Your Ultimate Buying Guide

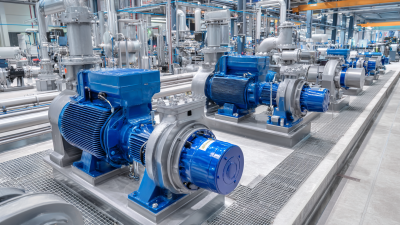

In the oil and gas industry, the choice of equipment is crucial for enhancing productivity and ensuring safety. Among these key components, pumps for oil play an essential role in various applications, including exploration, production, and transportation. According to a recent report by the International Energy Agency (IEA), global oil demand is projected to reach 101.5 million barrels per day by 2025, emphasizing the increasing need for efficient pumping solutions to support this demand.

Industry expert Dr. Jane Holloway, a leading authority on fluid dynamics, highlights the significance of selecting the right pumps for oil: "The efficiency and reliability of oil extraction processes hinge on the quality and performance of the pumping systems in use." As technology advances, the market for pumps for oil continues to evolve, offering a range of options tailored to specific operational requirements.

This comprehensive buying guide explores the top ten essential pumps for oil, detailing their features, applications, and the factors to consider when making your selection. Whether you are in upstream, midstream, or downstream operations, understanding the latest innovations in pump technology is vital for optimizing your operations and maintaining a competitive edge.

Top Trends Influencing Oil Pump Technology in 2025: What to Watch For

As we look towards 2025, several trends are set to reshape the oil pump technology landscape. One significant trend is the increasing emphasis on energy efficiency. Manufacturers are developing pumps that minimize energy consumption while maximizing output. This not only helps reduce operational costs but also aligns with global sustainability initiatives. Innovations like variable frequency drives (VFDs) are becoming standard, allowing for precise control over pump operations and reducing wasted energy.

Another crucial factor influencing oil pump technology is the integration of smart technology. The rise of the Internet of Things (IoT) allows pumps to be connected to centralized monitoring systems. This connectivity enables real-time data collection and analysis, leading to improved maintenance strategies and operational efficiency. Predictive maintenance powered by AI algorithms can foresee potential failures, thereby reducing downtime and extending the lifespan of equipment. As these technologies continue to evolve, they will play a vital role in transforming the oil industry, driving the adoption of more advanced and reliable pump solutions.

Top 10 Essential Pumps for Oil

| Pump Type | Max Flow Rate (GPM) | Max Pressure (PSI) | Efficiency (%) | Key Feature |

|---|---|---|---|---|

| Positive Displacement Pump | 500 | 300 | 85 | Self-priming |

| Centrifugal Pump | 800 | 250 | 90 | High flow rates |

| Gear Pump | 150 | 400 | 80 | Compact size |

| Diaphragm Pump | 100 | 200 | 75 | Leak-free operation |

| Peristaltic Pump | 50 | 150 | 70 | Gentle pumping |

| Vane Pump | 250 | 350 | 82 | Variable speed |

| Screw Pump | 600 | 500 | 88 | Consistent flow |

| Rotary Lobe Pump | 350 | 400 | 84 | Low shear |

| Submersible Pump | 300 | 250 | 72 | Underwater operation |

| Magnetic Drive Pump | 200 | 180 | 78 | No seals |

Key Performance Metrics: Understanding Oil Pump Efficiency Ratings

When selecting an oil pump, understanding its efficiency ratings is crucial for maximizing performance and lowering operational costs. Efficiency ratings, typically expressed as a percentage, indicate how effectively a pump converts input energy into hydraulic energy. According to the Hydraulic Institute, a highly efficient pump can operate at 85% efficiency or higher, significantly reducing energy consumption and prolonging equipment lifespan.

Key performance metrics include flow rate, head pressure, and mechanical efficiency. The American Petroleum Institute emphasizes that a pump's flow rate must match the operational requirements of the system it serves; otherwise, inefficiencies can lead to increased wear and tear. Additionally, proper sizing is critical. A study published in the Journal of Petroleum Technology indicates that improperly sized pumps can result in energy wastage of up to 20%, underscoring the importance of accurate calculations in the selection process.

Moreover, advancements in technology have led to improved designs, such as variable speed pumps that adapt to changing operational conditions, further enhancing efficiency. By prioritizing these metrics, buyers can ensure they choose pumps that not only meet their immediate needs but also contribute to a more sustainable and cost-effective operation over time.

Integrating Smart Technology: The Future of Automated Oil Pumps

The integration of smart technology into oil pumps marks a significant shift in how the industry operates. Automated oil pumps equipped with advanced sensors and connectivity features not only enhance operational efficiency but also improve safety and reliability. These smart systems can monitor performance in real time, providing operators with critical data to make informed decisions.

For instance, predictive maintenance features can alert users to potential issues before they lead to costly breakdowns, thus minimizing downtime and operational disruptions.

Moreover, the use of artificial intelligence in oil pumping technology is paving the way for more sophisticated automation processes. AI can analyze vast amounts of data collected from pumps and environmental conditions, optimizing performance and energy consumption. As a result, businesses can not only reduce their operational costs but also align with sustainability initiatives by minimizing their environmental footprint.

This shift toward smart, automated oil pumps signals a future where efficiency and innovation drive the oil industry forward, offering enhanced capabilities for both operators and consumers alike.

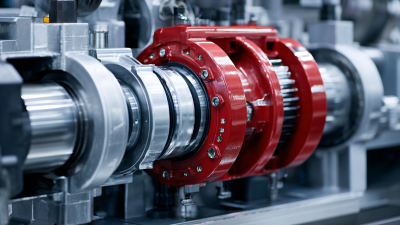

Comparative Analysis of Positive Displacement vs. Centrifugal Pumps in 2025

In 2025, the choice between positive displacement pumps and centrifugal pumps remains a critical consideration for oil industry professionals. Positive displacement pumps operate by trapping a fixed amount of fluid and forcing it through the discharge, making them ideal for applications requiring high viscosity handling and precise flow control. Their efficiency in transferring thick oil products often compensates for their potentially higher operational costs. Additionally, positive displacement pumps maintain a consistent flow rate regardless of pressure changes, making them particularly useful in scenarios where reliability is paramount.

In contrast, centrifugal pumps are favored for their ability to handle large volumes of fluids at lower viscosities. They operate by converting rotational kinetic energy to hydrodynamic energy, resulting in an increase in fluid velocity. This design allows centrifugal pumps to be lighter and more efficient in many applications, particularly where speed and volume are prioritized over viscosity. However, they are less effective with thicker fluids, making understanding the fluid properties critical during the selection process. As the oil industry evolves, the comparative advantages of each pump type will influence operational strategies, prompting ongoing analysis to optimize performance in varying conditions.

Top 10 Essential Pumps for Oil: Comparative Analysis of Positive Displacement vs. Centrifugal Pumps in 2025

Navigating Regulatory Standards: Compliance Tips for Oil Pump Manufacturers

When it comes to manufacturing oil pumps, compliance with regulatory standards is paramount. Various organizations set stringent guidelines that ensure products not only function effectively but also adhere to safety and environmental standards. Understanding these regulations can help manufacturers avoid costly fines and enhance their reputation in the industry. Key regulatory bodies, such as the Environmental Protection Agency (EPA) and the American Petroleum Institute (API), outline specifications needed to certify an oil pump for market readiness. Manufacturers must stay updated on these requirements, as they frequently change to accommodate new technology and environmental policies.

Moreover, implementing a proactive compliance strategy is crucial for oil pump manufacturers. This involves developing robust internal quality control systems and conducting regular audits to ensure adherence to regulatory standards. Training employees on compliance and the importance of maintaining high safety and performance standards can further enhance a company’s operational integrity. Collaboration with regulatory bodies during the design and testing phases can also facilitate smoother approval processes, allowing manufacturers to focus on innovation and efficiency while ensuring their products are compliant from the outset.

Related Posts

-

How to Choose the Right Pumps for Oil Based on Your Specific Needs

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency

-

Unlocking Efficiency: The Essential Guide to Choosing the Right Lube Oil Pump for Your Equipment

-

How to Choose the Right Type of Industrial Pump for Your Application

-

Unlock the Power of High Pressure Screw Pumps: Applications and Benefits Explained

-

2025 Top 5 Lube Oil Systems: Enhance Engine Performance and Longevity