High Pressure Screw Pump Tips for Optimal Performance and Maintenance

In the realm of industrial machinery, the high pressure screw pump stands out as a critical component for transporting fluids efficiently under demanding conditions. As noted by industry expert Dr. John Smith, a leading authority on fluid dynamics, "The effectiveness of high pressure screw pumps hinges on understanding not just their operation, but also the intricacies of their maintenance." This statement encapsulates the core of what is required for optimal performance, highlighting the dual focus on operational efficiency and preventative care.

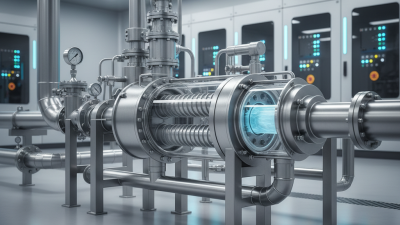

High pressure screw pumps are indispensable in various applications, including oil and gas, chemical processing, and water management. Their unique design allows for the steady transfer of high-viscosity fluids, making them particularly suited for challenging environments. However, without proper maintenance and performance optimization strategies, the efficiency of these pumps can diminish significantly, leading to costly downtimes and repairs.

To ensure that high pressure screw pumps deliver their best performance, operators must adopt a proactive approach to maintenance. By following industry best practices and leveraging expert insights, users can significantly enhance the longevity and reliability of these essential machines. This article aims to provide comprehensive tips and strategies for maintaining high pressure screw pumps to ensure they operate at peak performance.

Understanding High Pressure Screw Pumps and Their Functionality

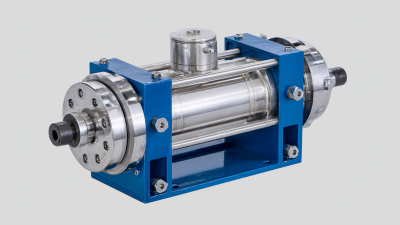

High pressure screw pumps are essential for various industrial applications, providing efficient and reliable fluid transfer. Their design typically consists of two or more rotors that mesh together, creating a series of chambers. As the rotors turn, they draw fluid into the pump and then transport it through the discharge port, generating high pressure. This functionality makes screw pumps particularly suitable for handling thick, viscous fluids that might clog other types of pumps. Their capacity to maintain a steady flow rate, even under varying pressures, is crucial in processes such as chemical manufacturing, oil extraction, and wastewater treatment.

Understanding the functionality of high pressure screw pumps involves recognizing the importance of their construction and operation. The rotors are usually made from durable materials that can withstand significant wear and tear, ensuring longevity and minimal maintenance. Additionally, the design minimizes turbulence and shear, which protects sensitive materials being pumped. Regular maintenance, such as monitoring rotor wear and ensuring proper lubrication, can greatly enhance pump performance and lifespan. By grasping the core principles of how high pressure screw pumps operate, users can optimize their functionality and ensure consistent operation in demanding environments.

Key Factors Affecting Performance in High Pressure Screw Pumps

High-pressure screw pumps are essential in various applications, and their performance can be significantly influenced by several key factors. One critical element is the operating conditions, including temperature and viscosity of the fluid being pumped. Higher viscosity fluids can lead to increased wear and tear on the pump components. It’s crucial to ensure that the pump is designed to handle the specific fluid characteristics to maintain efficiency and prolong its lifespan.

Additionally, proper alignment and installation of the pump can greatly affect its overall performance. Misalignment can cause excessive vibrations, which not only diminish efficiency but can also lead to premature failure of the pump. Regular maintenance is essential, and operators should monitor the pump for signs of wear or misalignment, addressing any issues immediately to prevent further complications.

To optimize performance, here are a few tips: Regularly check and replace filters to maintain fluid cleanliness, as contaminants can significantly hinder performance. Implement a routine lubrication schedule for bearings and seals to reduce friction and wear. Finally, always ensure that the pump operates within its designed pressure range to prevent excessive stress on the components. By focusing on these key factors and maintaining diligence in care, operators can achieve optimal performance from their high-pressure screw pumps.

Routine Maintenance Practices for Longevity and Efficiency

Routine maintenance is essential for ensuring the optimal performance and longevity of high-pressure screw pumps. According to industry studies, proper maintenance can increase the lifespan of these pumps by up to 50%, resulting in significant cost savings and improved efficiency. Regular inspections should be scheduled to assess components such as bearings, seals, and rotors for wear and tear. A report by the

Hydraulic Institute emphasizes that a proactive maintenance schedule, including routine cleaning and part replacement, minimizes the risk of unexpected breakdowns and keeps operational downtime to a minimum.

Moreover, lubrication practices are crucial in maintaining the integrity of high-pressure screw pumps. The American Society of Mechanical Engineers (ASME) suggests checking lubricant levels and the condition of lubricants every 1,000 operational hours. Proper lubrication reduces friction and heat generation, which are common causes of mechanical failure. Additionally, incorporating vibration analysis as part of your preventive maintenance routine can identify early signs of mechanical issues, thus preventing costly repairs. Keeping detailed maintenance logs can also enhance the overall maintenance process, ensuring that any patterns or recurring issues are identified and addressed promptly.

Common Issues and Solutions for High Pressure Screw Pump Operators

High pressure screw pumps are vital in many industrial applications, but they can present certain challenges if not properly maintained. One common issue operators may encounter is cavitation, which happens when vapor bubbles form in the liquid being transported and collapse violently, causing significant damage to the pump components. To mitigate this, maintaining appropriate inlet pressure and ensuring the fluid's vapor pressure is well below the operating pressure of the pump is essential. Regularly monitoring the flow rate and adjusting accordingly can also help prevent cavitation.

Another frequent problem is excessive wear on the pump's rotors and stators due to abrasive media or improper lubrication. Operators should conduct routine inspections and maintenance checks to look for signs of wear and tear. Using appropriate materials that suit the pumped media can enhance the longevity of the pump parts. Additionally, ensuring the pump is correctly lubricated according to the manufacturer's specifications can help minimize friction and extend the life of the equipment. By addressing these common issues proactively, operators can ensure optimal performance and prevent costly downtime.

Best Practices for Troubleshooting Performance Problems

When troubleshooting performance problems with high pressure screw pumps, it's crucial to first identify the symptoms. Common issues include unusual noises, fluctuations in pressure, or decreased flow rates. These symptoms can often indicate air leaks within the system, cavitation, or wear in critical components. To accurately diagnose the problem, conduct a thorough inspection, checking for leaks at seals and joints, and listen for atypical sounds that may suggest mechanical wear or misalignment.

Another important step in troubleshooting is to monitor the pump's operational parameters. Keeping track of the inlet and outlet pressures, as well as the temperature of the fluid being pumped, will provide valuable insights into performance issues. For instance, if the inlet pressure drops significantly, it may indicate a blockage or insufficient supply, impacting the pump’s efficiency. Additionally, inspecting the lubrication system to ensure proper oil levels and conditions can help prevent premature wear and maintain optimal function. Regular maintenance checks and systematic observation can significantly reduce the risk of performance-related problems.

High Pressure Screw Pump Tips for Optimal Performance and Maintenance

| Aspect | Best Practice | Troubleshooting Tip |

|---|---|---|

| Operational Efficiency | Regularly monitor flow rates and pressures. | If flow drops significantly, check for blockages. |

| Lubrication | Use high-quality lubricants as per manufacturer specification. | Inadequate lubrication can cause overheating; check oil levels monthly. |

| Seal Integrity | Inspect seals regularly for wear and tear. | If leakage occurs, replace seals immediately to prevent further damage. |

| Vibration Monitoring | Use vibration analysis tools to detect issues early. | Excessive vibration may indicate misalignment or imbalance; check installation. |

| Regular Maintenance | Schedule routine maintenance every 6 months. | If unexpected noises or performance issues arise, consult a technician immediately. |

Related Posts

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

-

Understanding the Benefits of Screw Pumps in Modern Industrial Applications

-

Top Benefits of Double Screw Pumps for Efficient Fluid Handling

-

Top Benefits of Positive Displacement Water Pumps and Their Uses