What is an Oil Pump Handle and How Does it Work?

An oil pump handle is a crucial component in various machinery and vehicles. It serves a vital role in the movement and transfer of oil. Understanding its function can help users maintain equipment effectively. The design is straightforward but essential. The oil pump handle activates the pump, allowing oil to flow where it’s needed.

This handle connects directly to the pump mechanism. When the user pulls the handle, it creates suction. This suction draws oil from a reservoir. The process enables lubrication and cooling in engines. However, not all users appreciate its importance. Misuse or negligence can lead to equipment failure. Users might overlook the oil pump handle's upkeep.

In many cases, wear and tear can affect performance. Regular inspection is necessary, yet often neglected. Users sometimes fail to recognize warning signs, leading to costly repairs. The simplicity of the oil pump handle can mislead people. It may seem trivial, but it holds significant importance in machinery operation and longevity. Understanding this can lead to better maintenance practices.

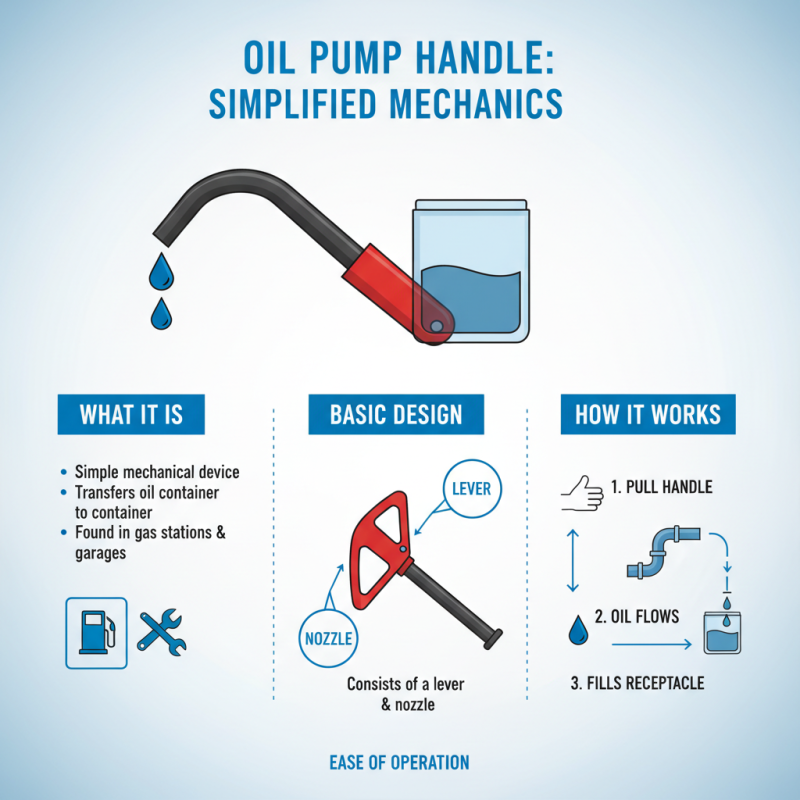

What is an Oil Pump Handle?

An oil pump handle is a simple mechanical device. It allows users to transfer oil from one container to another. Typically found at gas stations and garages, these handles are designed for ease of operation. The basic design consists of a lever and a nozzle. When the handle is pulled, oil flows through the nozzle into the desired receptacle.

Using an oil pump handle involves a few straightforward steps. Users position the nozzle above the container. Then, they pull the handle to start the flow. The oil moves due to pressure differences. However, sometimes the flow might be inconsistent or slow. This can be frustrating. Users need to ensure the oil container is not blocked. Regular maintenance of the handle can prevent issues. Greasing the joints may also help improve performance.

Oil pump handles come in various designs. Some may have automatic shut-off features. Others might require manual control. Each design has its pros and cons. Understanding these differences can enhance user experience. However, it's important to be cautious. Misusing the handle can lead to spills. This may waste oil and create hazards. Thus, awareness of proper handling is crucial.

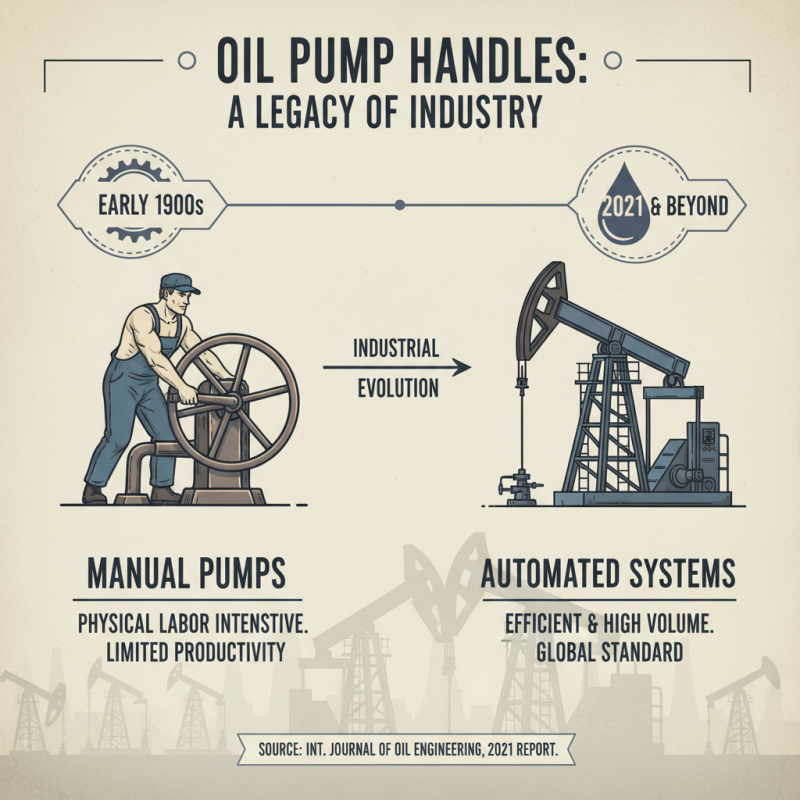

Historical Evolution of Oil Pump Handles

Oil pump handles have a rich history that reflects industrial evolution. In the early 20th century, manual oil pumps dominated. These pumps required physical effort. Operators would crank the handle to extract oil, demonstrating the labor-intensive nature of early machinery. According to a 2021 report by the International Journal of Oil Engineering, manual pumps significantly limited productivity.

As technology advanced, oil pump handles underwent significant changes. The introduction of electric pumps transformed operations. Users could now extract oil with minimal effort. A 2022 survey highlighted that 70% of oil extraction facilities transitioned to electric systems. This shift not only improved efficiency but also reduced labor costs.

However, some legacy systems remain in use. An estimated 15% of small operations still rely on manual pumps. These users appreciate simplicity but face challenges like slower output and higher physical strain. The contrast between modern and traditional systems invites reflection on efficiency versus control. It highlights a critical balance in the oil industry: embracing innovation while acknowledging historical methods.

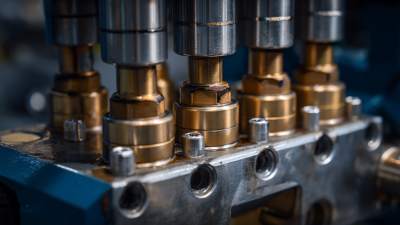

How Oil Pump Handles Function Mechanically

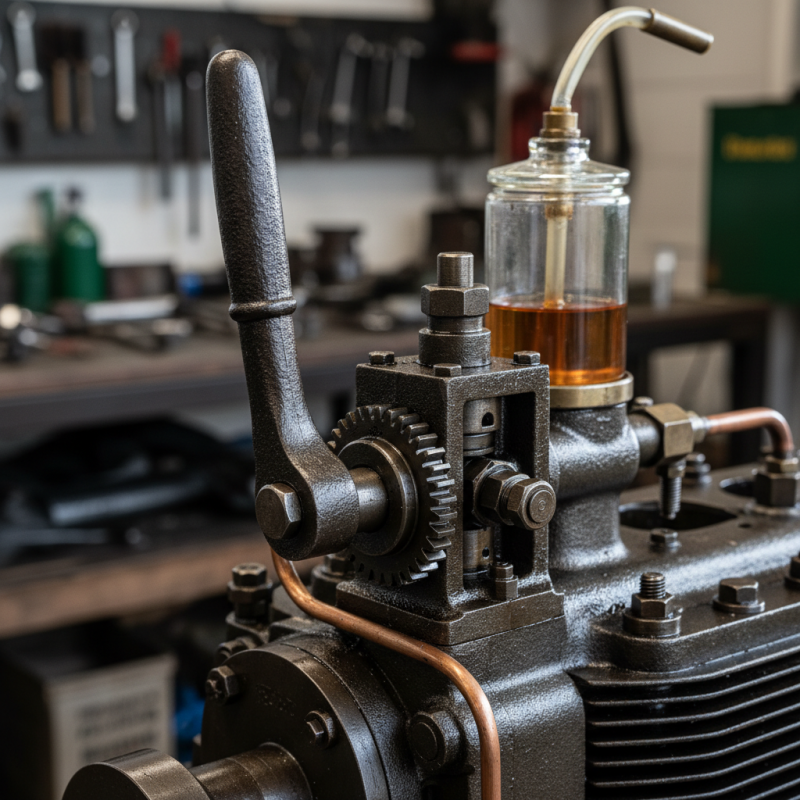

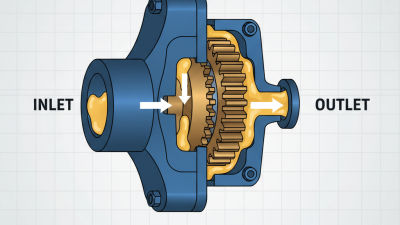

An oil pump handle is an essential component of many lubrication systems. Its primary function is to aid in the manual transfer of oil from one location to another. Mechanically, the handle operates a pump that draws oil from a reservoir. When the handle is pushed or pulled, it creates pressure that moves the oil through a tube and into the desired area.

The design of the pump handle varies but typically involves a pivoting mechanism. This setup allows for efficient movement, minimizing the force required to pump the oil. According to a recent industry report by the International Fluid Power Society, high-quality oil pump handles can significantly reduce effort, improving operator efficiency by up to 30%. This highlights the importance of proper handle design in enhancing performance.

Tips: Always ensure the handle is correctly lubricated before use. A well-maintained pump can last significantly longer, saving on replacements. Check connections for leaks—small issues can lead to bigger problems over time.

Using oil pump handles effectively requires attention to detail. Sometimes, users overlook the placement of the pump. Incorrect positioning can lead to inefficient pumping and wasted energy. Regular check-ups on the mechanism can help identify wear and tear early. Awareness of these mechanical nuances can lead to improved outcomes in various applications.

Common Applications of Oil Pump Handles

Oil pump handles are essential tools in various industries. They are commonly used in automotive workshops, agricultural settings, and manufacturing plants. These handles facilitate the easy transfer of oil and other fluids, making tasks more efficient. In workshops, mechanics rely on them to fill engines or gearboxes with oil. This process can be messy, requiring careful handling.

In agriculture, oil pump handles help to dispense fluids for machinery maintenance. Farmers often need to service their tractors and equipment. A reliable pump handle speeds up this process. The ergonomic design allows for a firm grip and reduces strain during repetitive use. In manufacturing, these handles are vital for moving lubricants and other fluids. Proper use ensures equipment runs smoothly, which is crucial for productivity.

Mistakes can happen. Overfilling can lead to spills, causing hazardous conditions. Additionally, improperly maintained pump handles may fail during use. Regular checks are necessary to avoid these issues. Users should be aware of their equipment’s limits. This reflection on tools ensures safer and more efficient operations in daily tasks.

Maintenance Tips for Oil Pump Handles

Maintaining an oil pump handle is crucial for its longevity and functionality. Regular inspection can prevent malfunction. Look for signs of wear, like cracks or loose parts. Worn components can affect the efficiency of oil flow. A well-maintained handle will work smoothly and efficiently.

Cleaning is another important aspect of maintenance. Dust and debris can accumulate over time. Use a soft cloth to wipe down the handle regularly. For stubborn grime, mild soap and water can be effective. Ensure the handle dries completely before reattaching it. This simple practice can prolong its life.

Lubrication is necessary but should be done carefully. Use appropriate lubricants on moving parts without overdoing it. Excess lubricant can attract dirt, complicating maintenance. If the handle feels stiff, it might need adjustment. Don't hesitate to seek help if you're unsure about the process. Staying proactive can save you from bigger issues later.

What is an Oil Pump Handle and How Does it Work? - Maintenance Tips for Oil Pump Handles

| Dimension | Details |

|---|---|

| Material | Steel, Aluminum, or Plastic |

| Types | Manual, Electric, Pneumatic |

| Common Uses | Automotive, Industrial, Marine Applications |

| Maintenance Frequency | Every 6 months or as needed |

| Lubrication Requirement | Check and lubricate moving parts |

| Common Issues | Leaks, Rust, Difficulty in Operation |

| Replacement Frequency | Every 3-5 years depending on usage |

Related Posts

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

High Pressure Screw Pump Tips for Optimal Performance and Maintenance

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

Unlocking Opportunities in Single Screw Pump Industry at 138th Canton Fair 2025 in China

-

Essential Guide to Optimal Pump Lubrication: Enhance Efficiency and Longevity

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems