Why Choose a Screw Vacuum Pump for Your Industrial Applications

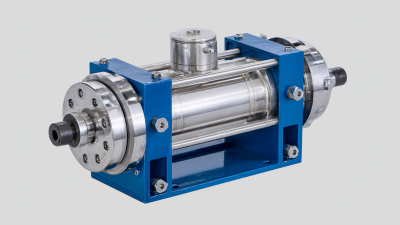

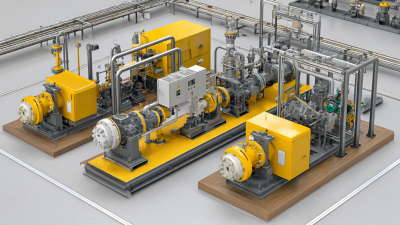

In the realm of industrial applications, choosing the right type of vacuum pump can significantly influence the efficiency and reliability of operations. Among various options available in the market, the screw vacuum pump stands out due to its unique design and functionality, making it an ideal choice for a wide array of industries. Characterized by a simple and robust construction, screw vacuum pumps offer high performance with low maintenance requirements, which is crucial for businesses striving for operational excellence.

The appeal of a screw vacuum pump lies not only in its ability to generate a strong vacuum but also in its energy efficiency, contributing to reduced operational costs. As industries seek to optimize productivity and minimize downtime, the integration of screw vacuum pumps can lead to substantial gains in both performance and sustainability. Whether in the process of material handling, packaging, or even chemical processing, the versatility of screw vacuum pumps makes them a favored solution for many industrial applications.

Furthermore, as industries evolve and demand continues to grow for more sustainable practices, the screw vacuum pump's performance advantages place it at the forefront of innovative pumping solutions. Emphasizing reliability and efficiency, this type of vacuum pump is increasingly recognized as a vital component in achieving effective industrial processes and meeting modern operational challenges.

Advantages of Screw Vacuum Pumps in Industrial Settings

Screw vacuum pumps have emerged as a go-to solution for various industrial applications due to their impressive efficiency and reliability. One of the primary advantages of these pumps is their ability to handle large volumes of gas while maintaining a constant vacuum level. This consistency is crucial in many industrial processes, ensuring quality control and optimal performance. Moreover, screw vacuum pumps are designed for continuous operation, which minimizes downtime and enhances productivity in high-demand environments.

Another significant benefit is the low maintenance requirement of screw vacuum pumps. Unlike traditional vacuum pumps, which often involve complex mechanical parts, screw pumps feature a simpler design with fewer moving components. This results in lower wear and tear, leading to reduced maintenance costs over time. Additionally, the absence of oil in many screw vacuum pumps eliminates the risk of contamination, making them ideal for applications where purity is paramount. In settings like food processing or pharmaceuticals, this characteristic is particularly beneficial, supporting stringent health and safety standards.

Advantages of Screw Vacuum Pumps in Industrial Settings

This chart represents the various advantages of screw vacuum pumps in industrial settings, highlighting their energy efficiency, low maintenance costs, noise levels, pumping speed, and overall durability in a visual format.

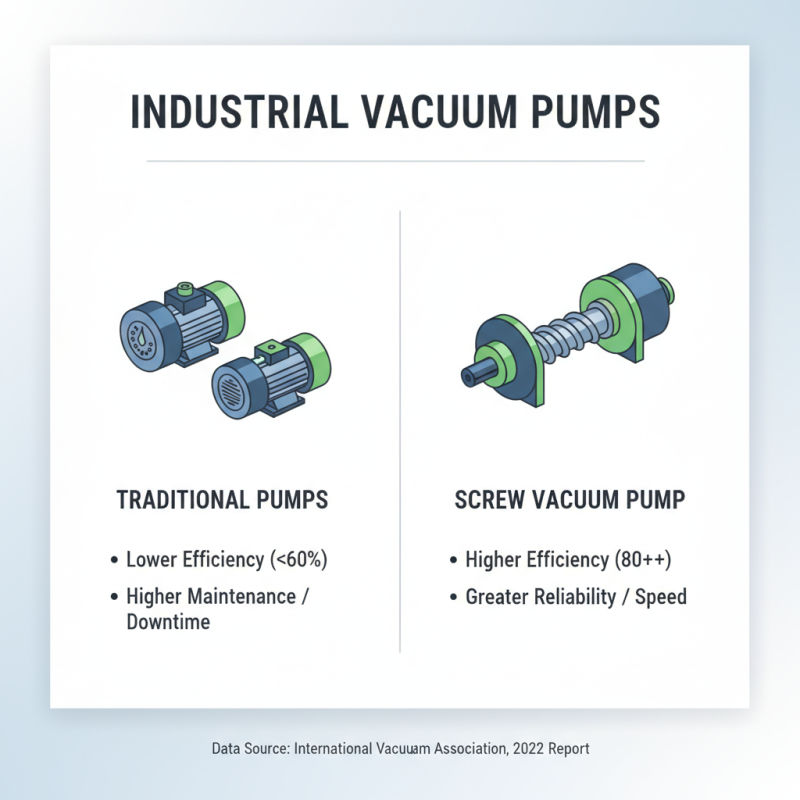

Comparison of Screw Vacuum Pumps to Other Vacuum Pump Types

When considering the right vacuum pump for industrial applications, the comparison between screw vacuum pumps and other types reveals several significant advantages. Traditionally, rotary vane pumps and diaphragm pumps have been popular choices; however, they often fall short in terms of efficiency and operational cost. According to a 2022 report by the International Vacuum Association, screw vacuum pumps deliver a higher pumping speed and greater reliability than these alternatives, often achieving an impressive efficiency rate of up to 80% or more. This efficiency not only translates into lower energy costs but also minimizes downtime due to maintenance, making screw pumps a sound investment for continuous operations.

In addition to efficiency, screw vacuum pumps exhibit superior performance in handling a wide range of gases and vapors. Unlike diaphragm and rotary vane pumps, which can struggle with condensable vapors or large gas loads, screw pumps maintain consistent performance and throughput. This adaptability makes them suitable for diverse applications, from food packaging to semiconductor manufacturing. Additionally, with advancements in technology, modern screw pumps can achieve ultimate pressures as low as 0.5 mbar, significantly outperforming many conventional options.

Tips: When selecting a vacuum pump, assess the specific requirements of your application, including the type of gases to be evacuated and the desired pressure levels. It may also be beneficial to consult with industry experts to gain insights into the most suitable pump for your specific needs. Regular maintenance checks are crucial; proactive care can further enhance the lifespan and efficiency of screw vacuum pumps.

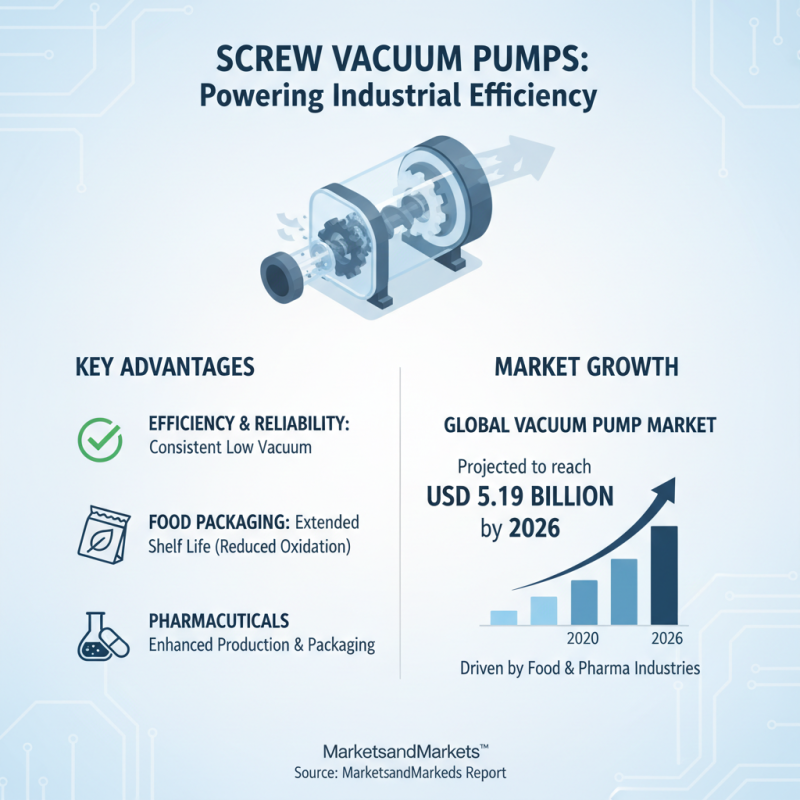

Applications of Screw Vacuum Pumps in Various Industries

Screw vacuum pumps are becoming increasingly popular across various industries due to their efficiency and reliability in producing low vacuum levels. In the food processing sector, for instance, these pumps are extensively employed to maintain vacuum during packaging. This allows for prolonged shelf life by minimizing the oxidation processes that can lead to spoilage. According to a report by MarketsandMarkets, the global vacuum pump market is projected to reach USD 5.19 billion by 2026, with growing demand driven by the food and pharmaceutical industries aiming for enhanced production and packaging processes.

In the chemical industry, screw vacuum pumps play a critical role in processes such as distillation and evaporation. With their ability to handle high vapor loads and provide a consistent vacuum level, they ensure product purity and process efficiency. A study from Research and Markets highlights that the chemical manufacturing sector is expected to witness significant growth, with the need for efficient vacuum solutions being a key driver. Additionally, screw pumps are favored in semiconductor manufacturing, where they are crucial for maintaining the cleanliness of vacuum systems, thereby supporting the production of high-quality microchips. The semiconductor market is expected to grow substantially, with vacuum technology being integral to the fabrication processes and overall equipment effectiveness.

Factors to Consider When Selecting a Screw Vacuum Pump

When selecting a screw vacuum pump for industrial applications, several key factors must be taken into account to ensure optimal performance and efficiency. Firstly, consider the required vacuum level and flow rate for your specific application. According to a report by the Vacuum Technology Association, the need for high efficiency in vacuum systems is critical, with improper sizing potentially leading to energy losses exceeding 30%. Therefore, accurately determining these specifications based on your process requirements is essential.

Another important factor is the operating environment. Screw vacuum pumps are known for their robustness, making them suitable for a variety of conditions, but understanding the temperature, humidity, and potential for dust or corrosive elements in your working environment is vital to selecting a durable model. Additionally, ease of maintenance and service intervals should be a priority, as regular upkeep is necessary to maintain performance—research indicates that systematic maintenance can extend a pump's operational lifespan by up to 40%.

Tips: Opt for a pump with built-in monitoring systems that can alert you to potential issues before they escalate. Regularly review the energy consumption data, as modern screw vacuum pumps often offer significant energy savings compared to older models, reducing long-term operational costs while enhancing productivity.

Maintenance and Longevity of Screw Vacuum Pumps in Operations

When it comes to industrial applications, the maintenance and longevity of screw vacuum pumps are pivotal for ensuring efficient operations. These pumps are known for their robust design and reliability, which contribute to lower overall operating costs. According to industry reports, screw vacuum pumps can achieve energy efficiency levels up to 50% compared to traditional piston or rotary vane pumps, reducing both energy consumption and maintenance needs over time. With fewer moving parts, screw vacuum pumps experience less wear, leading to longer operational lifespans—often exceeding 15 years with proper maintenance practices.

To maximize the longevity of screw vacuum pumps, regular maintenance is essential. This includes routine oil changes, monitoring of temperature and vibration levels, and ensuring that all seals and gaskets are in good condition. Operators should also consider implementing predictive maintenance techniques, such as using sensors to monitor performance parameters in real-time. This proactive approach can significantly reduce unexpected downtime.

Tips for Maintenance:

- Schedule quarterly inspections to identify potential issues before they escalate.

- Keep detailed records of maintenance activities and performance metrics to track changes over time.

- Train staff on the importance of maintenance and proper operation techniques to enhance the pump's lifespan.

By investing in proper maintenance routines, industries can ensure that their screw vacuum pumps operate at peak efficiency, leading to increased productivity and reduced costs.

Related Posts

-

Exploring the Benefits of High Pressure Positive Displacement Pumps in Industrial Applications

-

Top 5 Positive Displacement Pump Manufacturers You Should Know About

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

How to Choose the Right Lubrication Pump for Your Needs

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer