Top 10 Best Tar Pumps for Efficient Liquid Transfer Solutions

When it comes to efficient liquid transfer solutions, selecting the right equipment is crucial for achieving optimal performance. Among the various tools available, tar pumps stand out for their specialized design and capabilities in managing viscous liquids. Whether you are dealing with tar, thick oils, or other heavy fluids, a quality tar pump can streamline the process, ensuring safe, swift, and effective transfer while minimizing spillage and waste.

In this guide, we will explore the top 10 best tar pumps on the market today, highlighting their features, advantages, and suitability for different applications. From portable models ideal for temporary setups to robust systems designed for industrial use, each tar pump has unique specifications that cater to specific needs. By comparing various options, users can make informed choices that enhance their operational efficiency and reliability in fluid handling tasks. Join us as we delve into the essential characteristics that define the best tar pumps, empowering you to find the perfect solution for your liquid transfer challenges.

Understanding Tar Pumps: Types and Mechanisms

Tar pumps play a vital role in the efficient transfer of viscous liquids, making them essential for various industrial applications. These pumps come in different types, each designed to handle specific substances and conditions. Understanding the mechanism of tar pumps is key to selecting the right one for your needs. Positive displacement pumps, for example, use mechanical action to move liquids, making them suitable for handling thick materials. Centrifugal pumps, on the other hand, are more efficient in transferring less viscous liquids but can sometimes struggle with exceptionally thick tar.

When choosing a tar pump, consider the viscosity and temperature of the liquid being transferred. Certain pumps are better equipped to handle high temperatures, while others might be more efficient for thicker substances. It's also crucial to assess the power source, as some pumps require more energy than others.

Tips: Regular maintenance can enhance the performance and longevity of your tar pump. Always check for any blockages or leaks before use, and keep the pump clean to prevent buildup of materials. Additionally, familiarize yourself with the manufacturer's guidelines to ensure you are operating the pump within its specified limits for optimum safety and efficiency.

Key Features to Consider When Choosing a Tar Pump

When selecting a tar pump for efficient liquid transfer, several key features should be at the forefront of your decision-making process. First and foremost, the pump's flow rate is a crucial element. According to industry reports, an optimal flow rate can significantly reduce transfer time, enhancing productivity. Pumps with flow rates exceeding 10 gallons per minute are often recommended for heavy-duty tasks, ensuring that large volumes of tar can be moved quickly and efficiently.

Durability and material composition are also vital considerations, especially given the viscous nature of tar. Pumps constructed from high-quality materials, such as stainless steel or chemical-resistant polymers, are less prone to wear and tear, reducing maintenance costs and downtime. Research shows that tar pumps made from robust materials can extend operational life by up to 30%, making them a cost-effective choice in the long run. Additionally, the ease of maintenance is critical; features like quick-disconnect fittings and self-priming capabilities can save operators both time and effort during routine upkeep, further impacting overall efficiency in liquid transfer operations.

Top 10 Best Tar Pumps for Efficient Liquid Transfer Solutions

| Pump Model | Flow Rate (GPH) | Max Viscosity (cP) | Material Compatibility | Weight (lbs) | Power Source |

|---|---|---|---|---|---|

| Model A | 120 | 1000 | Steel, Rubber | 35 | Electric |

| Model B | 90 | 800 | Plastic, Vinyl | 30 | Battery |

| Model C | 150 | 1200 | Aluminum, Nylon | 40 | Gasoline |

| Model D | 200 | 1500 | Stainless Steel | 50 | Electric |

| Model E | 110 | 900 | Polypropylene | 25 | Battery |

| Model F | 160 | 1300 | Cast Iron | 45 | Gasoline |

| Model G | 140 | 1100 | Teflon | 32 | Electric |

| Model H | 180 | 1400 | Nitrile | 38 | Battery |

| Model I | 130 | 950 | PVC | 28 | Electric |

| Model J | 125 | 600 | Fiberglass | 20 | Battery |

Top 10 Best Tar Pumps for Liquid Transfer: Product Overview

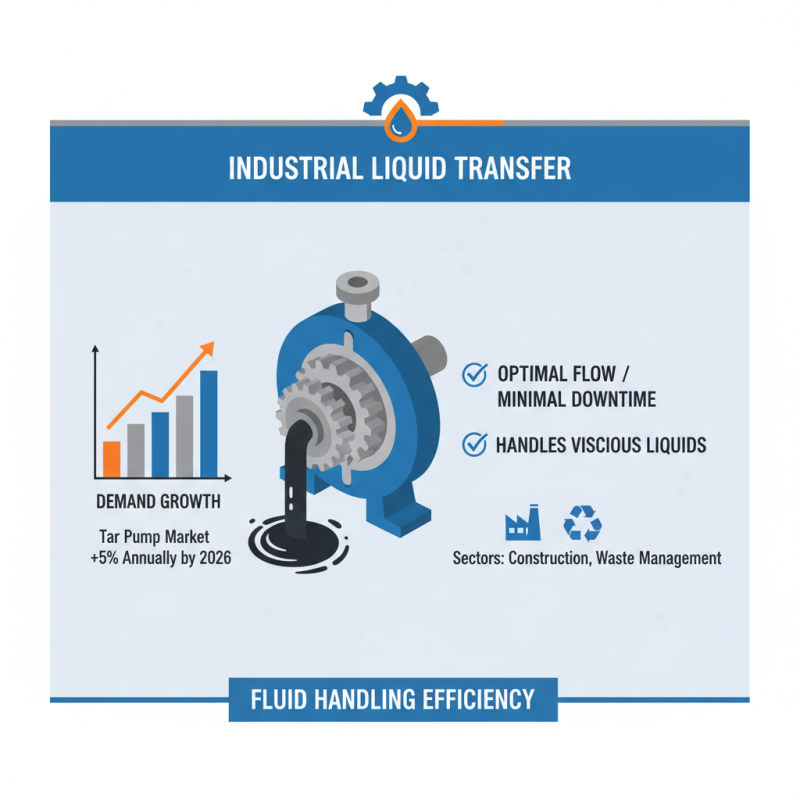

When it comes to efficient liquid transfer, especially in industrial applications, tar pumps play a crucial role. These pumps are designed to handle the viscous nature of tar, ensuring optimal flow and minimal downtime. According to a report by the Fluid Handling Association, the demand for specialized pumps, including those for thick liquids like tar, is expected to grow by 5% annually through 2026. This emphasizes the importance of selecting the right pump to enhance operational efficiency in industries ranging from construction to waste management.

The primary features to look for when evaluating tar pumps include viscosity handling capability, flow rate, and energy efficiency. A study published in the Journal of Industrial Fluid Mechanics highlights that pumps with variable speed drives can reduce energy consumption by up to 30% while providing better control over the transfer process. Moreover, materials used in pump construction must be compatible with the corrosive properties of tar, which allows for longer service life and reduced maintenance costs. Understanding these factors is essential for professionals seeking to optimize their liquid transfer operations effectively.

Comparative Analysis of Performance and Efficiency of Top Models

When assessing the performance and efficiency of tar pumps, it's essential to consider several key factors that impact their effectiveness in liquid transfer applications. First, the flow rate efficiency is a critical metric, as it determines how quickly and effectively the pump can move liquids from one location to another. Pumps with higher flow rates are often preferred for large-scale operations, but it’s vital to balance speed with the ability to handle the viscosity and density of the liquid being transferred.

Another important aspect of performance analysis is the energy consumption of each pump model. Efficient pumps take less energy to operate, which reduces operational costs over time. A comparative analysis should delve into how various models utilize energy and their impact on overall efficiency during prolonged use. Durability and maintenance requirements also play a significant role; pumps that require less maintenance and are built to withstand harsh conditions enhance long-term reliability, thus proving to be more efficient investments.

Additionally, user-friendliness features such as ease of setup, portability, and the convenience of control systems can significantly affect the overall efficiency of liquid transfer operations. A comparative approach highlights these attributes, allowing prospective users to identify models that not only deliver high performance but also simplify operational complexities. Ultimately, such an in-depth analysis helps users select the best tar pump that aligns with their specific needs while ensuring effective liquid transfer.

Maintenance Tips for Longevity and Optimal Performance of Tar Pumps

Maintaining tar pumps is crucial for ensuring longevity and optimal performance when transferring viscous liquids. Regular inspection and cleaning of the pump components can prevent the buildup of residue that may affect performance. It's recommended to check the inlet and outlet hoses regularly to ensure they remain free of blockages and leaks. Properly lubricating moving parts helps reduce friction and wear, extending the pump's operational life and enhancing efficiency.

In addition to regular maintenance, operators should be aware of the environmental conditions where the pump is used. Extreme temperatures can affect the viscosity of the liquid being transferred, leading to potential damages if tar pumps are subjected to harsh conditions without proper protection. Using appropriate insulation or housing can help mitigate these effects. Furthermore, always refer to the manufacturer's guidelines for any specific maintenance requirements that may apply to the pump model in use, ensuring that all maintenance practices align with recommended standards for safety and efficiency.

Top 10 Best Tar Pumps for Efficient Liquid Transfer

This chart illustrates the flow rates of the top tar pumps to help you choose an efficient liquid transfer solution. Higher flow rates indicate faster liquid transfer capabilities, which is essential for maintaining productivity in tar handling applications.

Related Posts

-

Innovative Tar Pump Solutions at the 2025 China Import and Export Fair for Industrial Growth

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

What is a High Pressure Positive Displacement Pump and How It Works in Industrial Applications

-

2025 Top 5 Lube Oil Systems: Enhance Engine Performance and Longevity

-

Why Choose a Screw Vacuum Pump for Your Industrial Applications