Top 10 Benefits of Using an Asphalt Pump for Your Projects?

In the world of construction and paving, the choice of equipment can significantly impact project efficiency and quality. The asphalt pump stands out as a vital tool for delivering viscous asphalt materials. According to the Asphalt Institute, the demand for efficient asphalt handling systems is on the rise, with a projected market growth of over 5% annually.

Industry expert Dr. Emily Carter, a leading authority in asphalt technologies, states, “Using a high-quality asphalt pump can reduce project timelines and improve overall quality.” Her insights highlight the pump's role in enhancing productivity while maintaining material integrity.

As the construction sector evolves, the advantages of asphalt pumps become apparent. They enable precise material delivery, reduce waste, and enhance worker safety. However, many still underestimate their importance. Proper training and awareness are crucial. Embracing asphalt pump technology can lead to significant improvements, yet the industry must address the knowledge gap surrounding its usage.

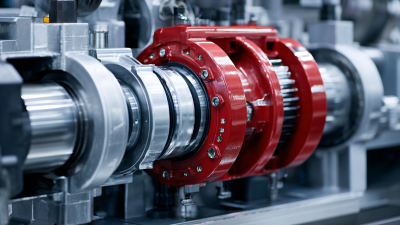

Understanding Asphalt Pumps: What They Are and How They Work

Asphalt pumps are essential tools for construction projects involving asphalt. These pumps transport hot asphalt from storage tanks to paving machines. Their design allows for precise control and efficient flow, ensuring that the asphalt is delivered at the right temperature and viscosity. Understanding how they work can help you optimize your project's workflow.

When using an asphalt pump, maintenance is key. Regularly check seals and filters to prevent leaks and clogs. If a pump is not regularly serviced, it can lead to operational failures during critical moments. Engage in routine inspections to ensure everything functions smoothly.

One tip is to familiarize yourself with the pump's specifications. Know the maximum capacity and pressure levels. Overworking a pump can cause overheating and costly breakdowns. Keep an eye on temperature and pressure gauges to maintain optimal performance. Sometimes, operators overlook these indicators, leading to inefficiencies that could have been avoided. Proper training for staff can mitigate these issues.

Top 10 Benefits of Using an Asphalt Pump for Your Projects

| Benefit | Description |

|---|---|

| Increased Efficiency | Asphalt pumps enable faster application of materials, reducing project completion times. |

| Reduced Labor Costs | Automation of asphalt handling decreases the need for manual labor, leading to significant cost savings. |

| Consistent Material Flow | Pumps provide a steady flow of asphalt, ensuring uniform application and better quality results. |

| Versatility | Can be used for various types of asphalt and applications, enhancing project flexibility. |

| Enhanced Safety | Minimizes the risk of spills and accidents associated with manual handling of hot asphalt. |

| Improved Quality Control | Precise control over temperature and mixture consistency leads to higher quality pavement. |

| Cost-Effectiveness | Reduces material waste and optimizes asphalt usage, leading to better overall budget management. |

| Easy Maintenance | Modern asphalt pumps are designed for easy cleaning and maintenance, reducing downtime. |

| Environmental Benefits | More efficient use of materials minimizes environmental impact and maximizes recycling opportunities. |

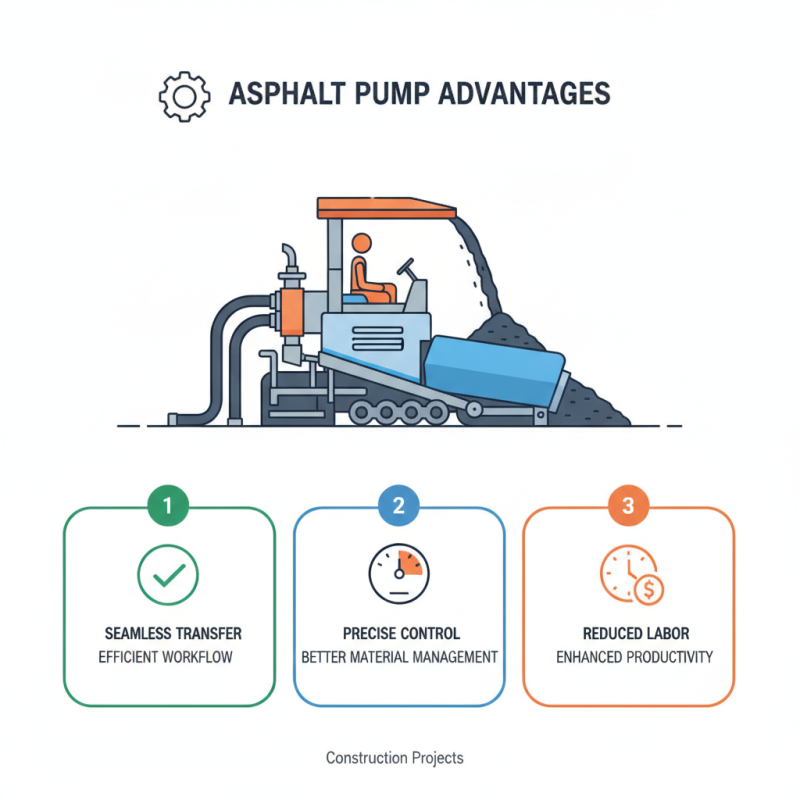

Key Advantages of Using Asphalt Pumps in Construction Projects

The use of asphalt pumps in construction projects offers several key advantages. These pumps enable seamless transfer of asphalt, ensuring efficient workflows. With precise control, workers can manage the flow of materials better. This reduces the time spent on manual labor and enhances overall productivity.

Furthermore, asphalt pumps can handle high temperatures effectively. This ability is crucial when working with molten asphalt. However, it's worth noting that maintenance is essential. Neglecting regular checks can lead to breakdowns, causing delays. Proper training for operators is also vital. Mismanagement can result in accidents or material wastage.

Asphalt pumps are typically durable and designed for heavy-duty use. Yet, users should be aware of potential wear over time. Factors such as frequency of use and lack of maintenance can accelerate this. Investing in proper care can extend the pump's lifespan. Ultimately, the right tools lead to smoother projects, but care needs to be taken every step of the way.

Improving Efficiency: How Asphalt Pumps Streamline Job Processes

Asphalt pumps play a crucial role in improving efficiency during construction projects. These machines reduce the time spent on transferring materials. According to industry reports, using asphalt pumps can decrease job completion time by up to 30%. Fast material transfer means less waiting time and more productive labor hours.

A significant benefit of asphalt pumps is their ability to handle various viscosity levels. They maintain a consistent flow, ensuring even distribution of asphalt. This reliability minimizes the risk of errors during application. However, improper setup can lead to blockages or uneven pumping, which can cause delays. Monitoring equipment performance is essential to avoid these pitfalls.

Job sites can be chaotic, with multiple tasks happening simultaneously. An efficient asphalt pump helps streamline these processes, coordinating tasks better. Reports indicate that a well-integrated asphalt pump system can enhance job site safety by reducing the need for manual handling. While technology offers benefits, it is vital to invest in proper training for operators. Without adequate training, even the best equipment can underperform. Regular maintenance is also critical, as neglect can lead to costly breakdowns and downtime.

Cost-Effectiveness of Asphalt Pumps Compared to Traditional Methods

Asphalt pumps have gained popularity for their cost-effectiveness compared to traditional methods. Using an asphalt pump reduces labor costs significantly. Workers spend less time handling materials manually. This efficiency saves both time and money, making projects more profitable.

Moreover, the reliability of asphalt pumps minimizes wasted materials. Traditional methods often lead to spills and excess wastage. With asphalt pumps, the application is targeted and precise. This not only conserves materials but also cuts down on cleanup costs.

However, there are considerations. The initial investment in equipment can be high. Not every project might justify this cost. It’s essential to assess project scale and budget before deciding. In some cases, smaller projects might still benefit from hand application methods. Evaluating individual needs is crucial for making the right choice.

Safety Considerations When Using Asphalt Pumps on Job Sites

Asphalt pumps are powerful tools used on construction sites. Their benefits are clear, but safety is crucial. Operators must wear protective gear, including gloves and goggles. The material itself can be extremely hot and can cause burns. Training is necessary. Workers should understand how to operate asphalt pumps safely.

Consider the risks of spills. An asphalt spill can create hazards. It's essential to have spill kits available on site. Workers must know how to use them. Regular maintenance can prevent accidents. A well-maintained pump is less likely to malfunction. Still, even with precautions, accidents can happen.

Keeping the work area clean is vital. Debris can become a tripping hazard. Easy access to tools is essential. Allowing room for movement reduces risks. Take a moment to review safety protocols. Miscommunication can lead to dangerous situations. Always encourage teamwork. Remember, safety comes first on every job site.

Top 10 Benefits of Using an Asphalt Pump for Your Projects

The chart above displays the top 10 benefits of using an asphalt pump for construction projects, rated on a scale from 1 to 10. These benefits highlight the importance of asphalt pumps in enhancing efficiency, safety, and overall project management.

Related Posts

-

Top 10 Essential Pumps for Oil: Your Ultimate Buying Guide

-

Top 5 Positive Displacement Pump Manufacturers You Should Know About

-

Essential Guide to Optimal Pump Lubrication: Enhance Efficiency and Longevity

-

2026 Best Rotary Positive Displacement Pumps for Optimal Performance?

-

2026 Best Oil Lubrication Pump for Enhanced Machinery Performance?

-

The Essential Role of Lubrication Pumps in Enhancing Equipment Lifespan and Efficiency