Top Cavity Pumps for 2025 Applications and Benefits You Should Know

In the evolving landscape of industrial pumping solutions, cavity pumps stand out for their remarkable efficiency and versatility. As we look towards 2025, understanding the applications and benefits of these pumps becomes increasingly crucial for industries ranging from food processing to chemical manufacturing. According to renowned expert Dr. John Mitchell, a specialist in fluid dynamics and cavity pump technology, “The adaptability of cavity pumps allows them to meet the diverse demands of modern industries, ensuring consistent performance and reliability.”

Cavity pumps, with their unique design, are particularly effective in handling challenging materials, including viscous and non-Newtonian fluids. This capability not only broadens their range of applications but also enhances operational efficiency in various sectors. As industries seek sustainable and cost-effective solutions, the importance of cavity pumps will only continue to grow. Given the current trends and the push for innovation, the coming year holds the potential for significant advancements in cavity pump technologies that could redefine industry standards.

As we delve deeper into the topic, we will explore the top cavity pumps expected to dominate applications in 2025, the technological benefits they offer, and how they can drive productivity and sustainability across different sectors.

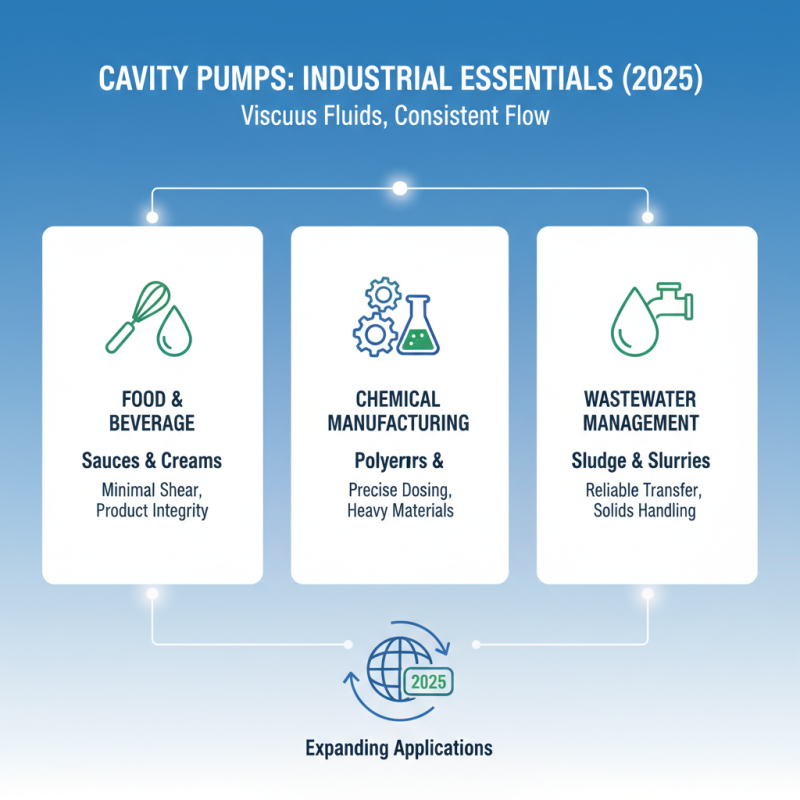

Top Applications of Cavity Pumps in 2025 Industries

Cavity pumps are becoming increasingly essential in various industries due to their unique ability to handle viscous fluids and provide consistent flow rates. In 2025, their applications are expected to expand further in sectors such as food and beverage processing, chemical manufacturing, and wastewater management. In the food industry, cavity pumps are ideal for transferring products like sauces and creams, ensuring minimal shear and maintaining product integrity. Similarly, in chemical manufacturing, they efficiently transport polymers and adhesives, which often require precise dosing and handling of heavy materials.

Tips for selecting the right cavity pump include considering the fluid characteristics and required flow rate. Ensure that the pump’s materials are compatible with the fluids to avoid corrosion and degradation. Additionally, evaluate the maintenance requirements, as a pump that is easy to service can save time and money in the long run.

Moreover, in wastewater management, cavity pumps play a crucial role in moving sludge and other thick materials. Their robust design allows them to function effectively in harsh environments, providing reliable operations even under difficult conditions. As industries look to optimize efficiency and productivity, understanding the diverse applications of cavity pumps will be key to leveraging their benefits fully in the coming years.

Key Benefits of Using Cavity Pumps for Fluid Management

Cavity pumps are increasingly recognized for their efficiency and versatility in various fluid management applications. These pumps provide several key benefits, particularly in industries dealing with viscous and abrasive fluids. According to a study published by the Global Pump Industry Association, cavity pumps can reduce operational costs by up to 20% compared to traditional pumping methods, due in part to their ability to handle thicker fluids with minimal shear. This efficiency is particularly advantageous in sectors such as food processing, oil and gas, and chemical manufacturing, where maintaining the integrity of the fluid is crucial.

Another significant advantage of cavity pumps is their inherent self-priming capability and low maintenance requirements. With fewer moving parts than conventional pumps, they minimize wear and tear, which leads to longer operational life and reduced downtime. A report from the European Fluid Handling Market indicates that companies utilizing cavity pumps experience maintenance costs that are 30% lower than those using centrifugal pumps. Additionally, their design allows for easy handling of solids in suspension, making them ideal for applications involving slurries or mixtures, thus broadening their utility in various demanding environments. Overall, the adoption of cavity pumps is proving to be a strategic choice for businesses aiming to enhance fluid management efficiency while optimizing cost and reliability.

Top Cavity Pumps for 2025 Applications and Benefits

This bar chart illustrates the key benefits of using cavity pumps for fluid management in various applications in 2025. The benefits include efficiency, versatility, durability, and maintenance ease.

Comparative Analysis of Leading Cavity Pump Brands for 2025

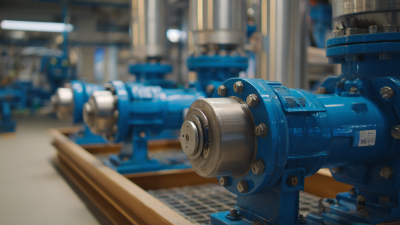

When considering cavity pumps for 2025 applications, a comparative analysis of the leading brands reveals several key factors that could impact performance and efficiency. The primary considerations include the material construction, the technology used in the pump design, and the specific operational requirements of different industries. Many top manufacturers focus on advanced materials that improve wear resistance and chemical compatibility, which are crucial in various applications like oil and gas, food processing, and wastewater management.

Efficiency and energy consumption are additional critical aspects that differentiate these cavity pumps. Brands are increasingly investing in innovative technologies to enhance flow rates and reduce operational costs. Furthermore, features such as self-priming capabilities and minimal maintenance requirements are becoming standard, catering to industries that require reliability and durability in challenging environments. Understanding these comparative advantages will help companies select the most suitable cavity pump for their specific needs in 2025.

Innovations in Cavity Pump Technology to Watch This Year

In 2025, the landscape of cavity pump technology is expected to transform significantly, driven by innovative design and advancements aimed at enhancing efficiency and reliability. One of the most notable trends is the integration of smart technology, such as IoT connectivity, allowing for real-time monitoring and predictive maintenance. This shift is not only optimizing operational efficiency but also minimizing downtime and maintenance costs for various industries, including oil and gas, wastewater treatment, and chemical processing.

Moreover, manufacturers are increasingly focusing on materials science to develop pumps that can withstand harsher chemicals and conditions, thereby extending their lifespan. The introduction of advanced sealing technologies is also noteworthy; these innovations reduce leaks and improve environmental safety, addressing both regulatory requirements and sustainability goals. By adopting these cutting-edge features, businesses can ensure more resilient operations while reducing their environmental footprint.

As we look forward to the advancements in cavity pump technology, it is clear that 2025 will be a pivotal year for enhancing productivity and safety in fluid management systems.

Maintenance Best Practices for Optimal Cavity Pump Performance

Maintaining the optimal performance of cavity pumps is crucial for maximizing operational efficiency and minimizing downtime. According to a recent industry report, over 30% of pump failures can be attributed to improper maintenance practices. To ensure that cavity pumps operate effectively, regular inspections and adherence to recommended maintenance schedules are essential. This includes monitoring the pump's operating conditions, such as temperature and pressure, which can help identify anomalies before they lead to significant issues.

A comprehensive maintenance plan should encompass routine tasks such as checking for wear on critical components, ensuring proper lubrication, and verifying seal integrity. The Hydraulic Institute indicates that implementing a predictive maintenance strategy can enhance pump reliability by up to 20%, significantly reducing repair costs. Moreover, keeping records of maintenance activities and performance metrics allows operators to spot trends and preemptively address potential problems. By adopting these best practices, industries can prolong the lifespan of cavity pumps, ultimately improving their productivity and bottom line.

Related Posts

-

Exploring the Benefits of Cavity Pumps in Industrial Applications: A Comprehensive Guide

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Top 2025 Rotary Screw Pump Innovations: What You Need to Know

-

10 Best Rotary Screw Pumps for Efficient Fluid Transfer in 2023

-

Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines

-

Top 5 Positive Displacement Pump Manufacturers You Should Know About