Top 10 Lube Oil Pump Types You Should Know About?

In the realm of industrial machinery, the lube oil pump plays a crucial role. These pumps ensure efficient lubrication, reducing wear and prolonging equipment life. According to a report by the Global Oil Pump Market Analysis, the demand for advanced lube oil pumps is expected to grow significantly in the coming years. Industry expert, Dr. Mark Thompson, emphasizes, "Understanding different lube oil pump types is essential for optimal performance."

This growth reflects the need for better efficiency and reliability in various applications. From automotive to manufacturing, lube oil pumps help maintain system integrity. For instance, centrifugal pumps are widely used due to their ability to handle high flow rates. However, choosing the right pump can be challenging. Many users overlook the specific requirements of their machinery. This often leads to suboptimal performance and increased maintenance costs.

Innovation is driving the lube oil pump sector. New technologies offer improved features, yet some designs remain outdated. There is a gap between new developments and real-world applications. It's crucial to address these disparities to harness the full potential of lube oil pumps.

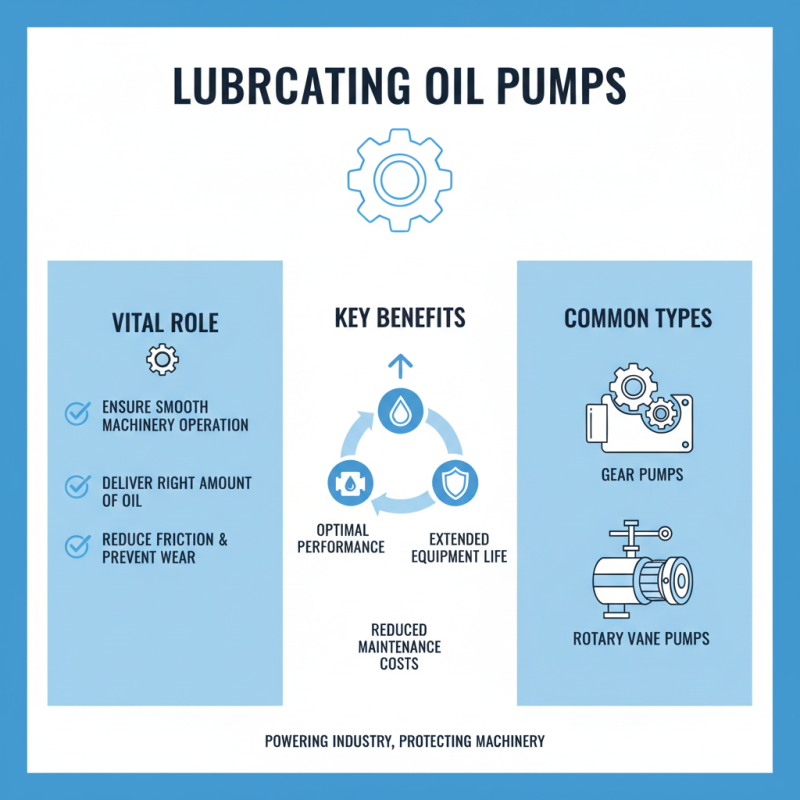

Overview of Lubricating Oil Pumps

Lubricating oil pumps play a vital role in various industries. These pumps ensure smooth operation of machinery by delivering the right amount of oil. A well-functioning oil pump reduces friction and prevents wear. There are various types of lubricating oil pumps, each suited for specific applications. Some common types include gear pumps, diaphragm pumps, and rotary vane pumps.

Gear pumps use gears to move oil. They are efficient and widely used due to their simplicity. Diaphragm pumps, on the other hand, utilize a flexible diaphragm to create a vacuum. This design helps avoid contamination in sensitive applications. Rotary vane pumps provide smooth flow and are often found in commercial vehicles. Each type has its advantages and limitations.

In understanding these pumps, one must consider the specific needs of their operations. A mismatch can lead to inefficiency or damage. Recognizing the right pump type requires experience. Yet, even skilled operators may overlook key details. This complexity can lead to significant operational challenges. Choosing the right lubrication pump can seem daunting, but it is essential for equipment longevity.

Types of Positive Displacement Lubrication Pumps

Positive displacement lubrication pumps are essential in many industries. They ensure a consistent flow of lubricating oil. Understanding the types of these pumps can help in choosing the right one for your needs.

There are several common types of positive displacement pumps. Gear pumps are popular due to their simplicity. They use interlocking gears to move oil smoothly. Another type is diaphragm pumps. These pumps can handle viscous fluids easily. They create pressure through a flexible diaphragm, which offers good sealing.

Progressive cavity pumps are also noteworthy. They provide a steady flow and are great for handling thick fluids. However, their complexity might be a downside. Each pump type has its pros and cons. It's important to assess your specific application. Sometimes, what seems ideal on paper may not work well in practice. Investing time in understanding these pumps can save you from costly mistakes later on.

Top 10 Lube Oil Pump Types

Comparative Analysis of Centrifugal Lube Oil Pumps

Centrifugal lube oil pumps are critical in industrial applications. They offer efficiency in transferring oil due to their design. With a mechanical advantage, centrifugal pumps can handle large volumes with minimal energy consumption. Reports indicate that these pumps can achieve efficiencies upwards of 80%. This highlights their effectiveness compared to other pump types.

However, centrifugal pumps are not without limitations. They often struggle with high-viscosity oils. This can lead to cavitation issues, impacting overall performance. In demanding conditions, the selection of the right pump becomes crucial. A study by the Fluid Power Journal indicated that improper pump selection could decrease operational margins by over 15%.

When evaluating centrifugal lube oil pumps, consider factors such as flow rate and pressure requirements. Misalignment or poor maintenance can lead to failures, increasing downtime. Periodic assessments can mitigate these risks. Understanding the specific needs of your application will ensure a more reliable operation. Choose wisely, as the wrong type can cost both time and money.

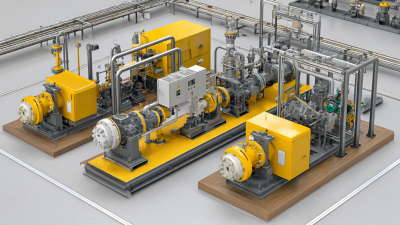

Applications and Industries Utilizing Lube Oil Pumps

Lube oil pumps play a crucial role in various industries and applications. They ensure the smooth operation of machinery. These pumps lubricate engines, compressors, and turbines, preventing wear and tear. In automotive sectors, lube oil pumps maintain fluid circulation in engines. This helps in reducing friction and improving efficiency.

Industrial applications are equally reliant on these pumps. Manufacturing plants use lube oil pumps to lubricate heavy machinery. Without adequate lubrication, equipment can fail. This results in costly downtime and repairs. Marine industries also depend on lube oil pumps for vessel engines. Lubrication here is vital for safety and performance.

Some might overlook the significance of lube oil pumps. However, neglecting maintenance can lead to catastrophic failures. Many operations fail to prioritize proper lubrication systems. This results in risks that could have been avoided. It's essential to acknowledge the often unseen but critical role of these pumps in daily operations.

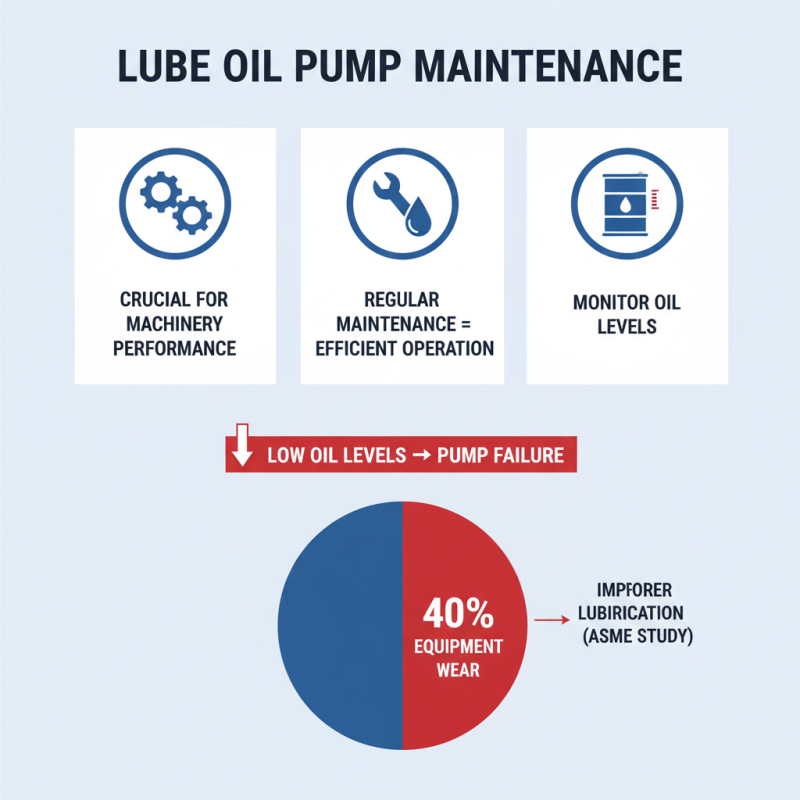

Maintenance Tips for Optimal Lube Oil Pump Performance

Lube oil pumps play a crucial role in machinery performance. Regular maintenance ensures they work efficiently. Monitoring oil levels is vital. Low oil can lead to pump failure. According to a study by the American Society of Mechanical Engineers, improper lubrication accounts for 40% of equipment wear.

Periodic filter changes are essential too. Dirty filters restrict flow and can cause overheating. Signs of wear may include unusual noises or reduced pressure. Regular inspections can help catch these issues early. A report from the Society of Tribologists and Lubrication Engineers indicates that proper maintenance can extend the life of a lube oil pump by up to 30%.

It’s a common oversight to ignore the temperature of the oil. High temperatures can degrade oil quality. Oil should remain within manufacturer specifications. If temperatures rise, pump performance declines. Keeping a log of maintenance activities helps identify patterns. An operator may notice recurring issues that require more attention. Addressing small problems can prevent bigger breakdowns later.

Related Posts

-

2026 Top Displacement Pumps Innovations and Trends to Watch?

-

How to Choose the Right Screw Pump for Your Industrial Needs

-

Exploring the Efficiency of Displacement Pumps: A Comprehensive Guide to Optimal Fluid Management in Industry

-

Top 10 Best Tar Pumps for Efficient Liquid Transfer Solutions

-

Top Benefits of Double Screw Pumps for Efficient Fluid Handling

-

2025 Top 5 Lube Oil Systems: Enhance Engine Performance and Longevity