Top Lube Pump Types for Efficient Fluid Transfer Solutions?

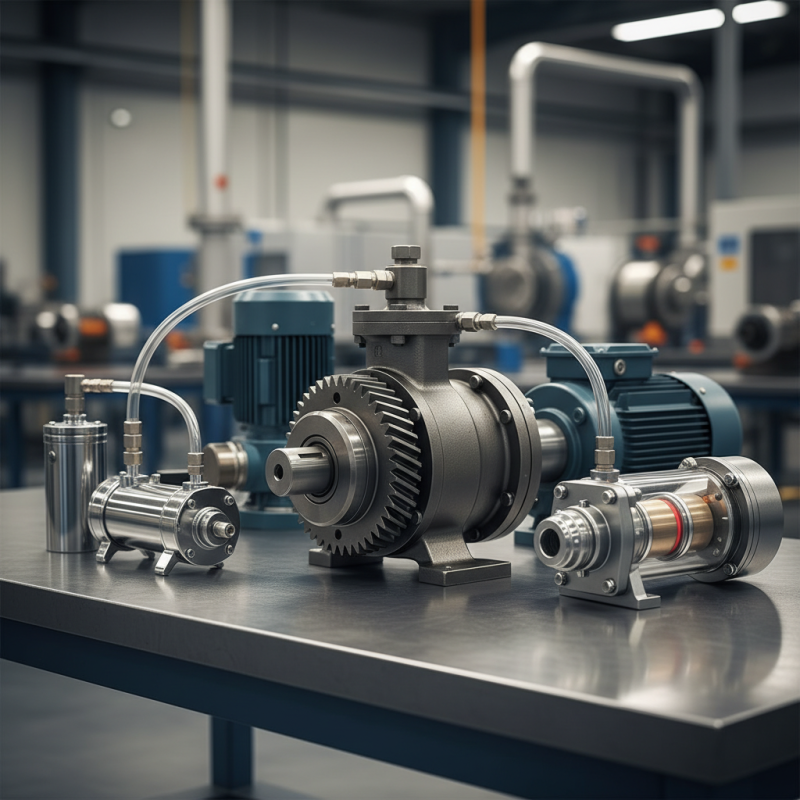

In today's fast-paced industrial landscape, efficient fluid transfer is crucial. Among the various components that facilitate this process, the lube pump stands out. These pumps play a vital role in ensuring machinery operates smoothly and effectively. Choosing the right lube pump type can significantly impact system performance.

Different lube pump types serve various applications and environments. Some are designed for heavy-duty use, while others cater to light machinery. It's important to analyze your specific needs. A failure to select the right pump could lead to inefficiencies and even equipment damage. Assessing the lube pump's flow rate, pressure, and compatibility with fluids is essential for optimal function.

Understanding the various lube pump options available is crucial for achieving reliable fluid transfer. Each pump type has distinct advantages and limitations. Some require more maintenance than others. The right choice ensures long-term durability and performance. Don't overlook the importance of research. Making an informed decision can save time and resources in the long run.

Overview of Lube Pumps and Their Importance in Fluid Transfer

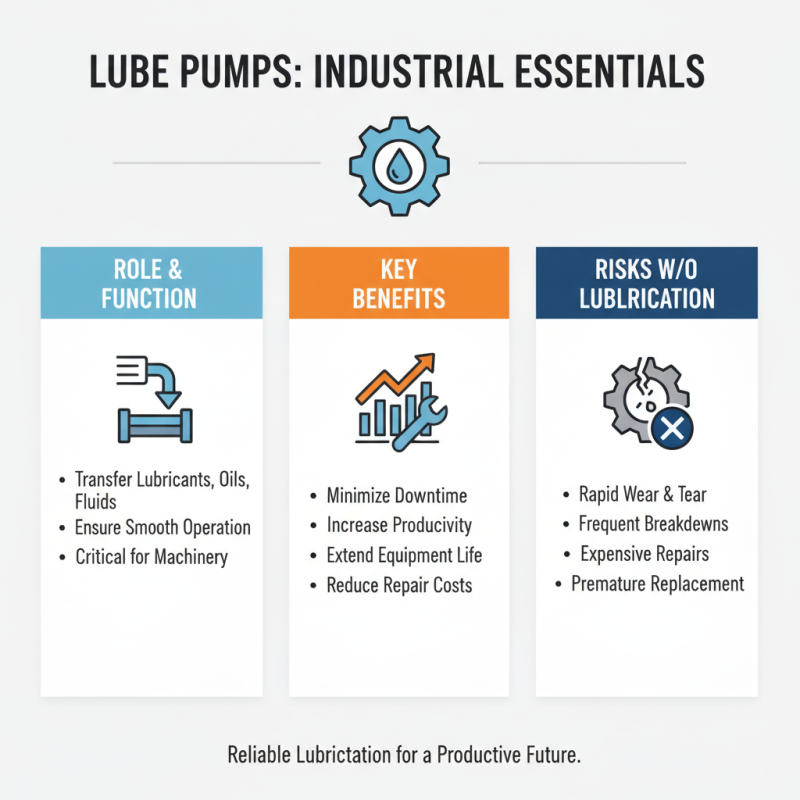

Lube pumps play a critical role in various industries. They ensure the efficient transfer of lubricants, oils, and other fluids. An effective lube pump minimizes downtime in machinery, enhancing productivity. Without proper lubrication, equipment can wear down quickly. This can lead to costly repairs and replacements.

Different types of lube pumps are available for specific applications. Gear pumps are often used for their reliability. Diaphragm pumps provide excellent chemical compatibility. However, choosing the right pump can be challenging. Some users might overlook the importance of pump maintenance. Regular checks can prevent unexpected failures.

Fluid transfer solutions are about more than just moving liquids. They involve precision and efficiency. A well-chosen lube pump saves time and resources. Yet, some might rush the selection process. They miss vital factors like flow rate and viscosity. This oversight can result in suboptimal performance. The right attention to detail is essential for successful fluid management.

Types of Lube Pumps: A Comparative Analysis of Mechanisms and Applications

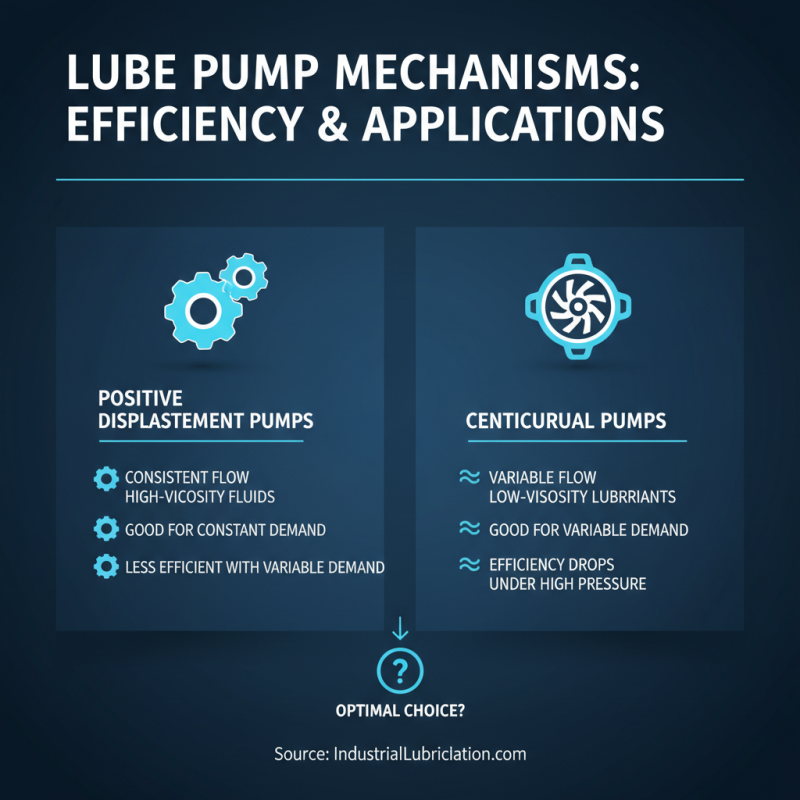

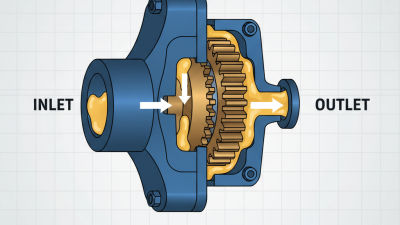

When it comes to lube pumps, the choice of mechanism greatly impacts efficiency. Various types exist, each serving specific applications. Positive displacement pumps, for instance, provide consistent flow. They work well in high-viscosity fluids but can struggle with variable demands. On the other hand, centrifugal pumps are better suited for lower viscosity lubricants. However, they may lose efficiency under certain pressure conditions.

Electric lube pumps have become popular for their reliability and automation. They require less manual intervention, making them appealing for large systems. Yet, one must consider the added complexity of electronics. Manual pumps still hold value for small-scale operations. They are simple to use but can be labor-intensive. Understanding the right application is crucial for optimal performance.

Some pumps are designed for specific environments. For example, high-temperature fluids require materials capable of withstanding heat. There are always trade-offs. A pump's design might enhance one feature but compromise another. Assessing the right type involves weighing these factors carefully. One must not overlook routine maintenance, as it affects longevity and productivity.

Key Features to Consider When Selecting a Lube Pump for Your Needs

When selecting a lube pump, several key features are essential to ensure optimal performance. One critical factor is flow rate. This measurement indicates how quickly fluid can be transferred. It's crucial to match the flow rate to your system’s requirements. A pump with too high or too low a flow rate can lead to inefficiencies. Another important element is viscosity compatibility. Lube pumps vary in capability to handle different fluid viscosities. Make sure the chosen pump suits the specific lubricant used.

Durability is another consideration. A well-built pump will withstand wear and tear. Materials should resist corrosion and damage from lubricants. In environments with extreme temperatures, temperature tolerance becomes vital. Pumps operating under high or low temperatures can malfunction if not designed for such conditions. Additionally, maintenance requirements can't be overlooked. Some pumps require frequent servicing, while others are designed to be low-maintenance. Recognizing your operational needs will aid in making the right choice. It's essential to reflect on these aspects to prevent potential issues.

Top Lube Pump Types for Efficient Fluid Transfer Solutions

Maintenance Practices for Optimal Lube Pump Performance and Longevity

Maintaining lube pumps is vital for their efficiency and life span. Regular inspections can spot issues early. Small leaks can become big problems. Check seals and fittings frequently. Ensure there is no debris in the pump area. Debris can lead to blockages and reduced performance.

Lubrication is key for optimal function. Use the correct lubricant type to avoid compatibility issues. Over-lubricating can be as harmful as under-lubricating. Watch for overheating during operation. If the pump becomes too hot, it may indicate a problem.

Operating conditions also affect pump life. Extreme temperatures and dust can cause wear over time. It’s crucial to educate staff on proper operating procedures. Training can reduce mistakes. Remember, even small changes can improve performance and extend longevity.

Emerging Technologies in Lube Pump Design for Enhanced Efficiency

In the world of lube pumps, emerging technologies are transforming fluid transfer solutions. Modern designs focus on enhancing efficiency and reducing operational costs. According to a recent industry report, the adoption of smart sensors in lube pumps can improve performance accuracy by up to 25%. These advancements enable real-time monitoring, allowing operators to optimize flow rates effectively.

Many lube pumps now utilize advanced materials that resist corrosion and wear. This innovation extends the lifespan of equipment, thereby reducing maintenance costs. The integration of variable frequency drives (VFDs) also leads to energy savings of approximately 30%. However, not every company has embraced these technologies fully. Some still rely on outdated systems, which can lead to inefficiencies.

Tip: Regular maintenance checks can identify issues before they escalate. Small leaks or wear can spiral into costly repairs.

As industry standards evolve, companies must adapt to stay competitive. Embracing modular designs can facilitate easier upgrades in the future, but many organizations hesitate to invest in these systems. It raises questions about balancing initial costs against long-term savings.

Tip: Collaborate with engineers to evaluate your current lube pump setup. Understanding your system’s weaknesses can guide necessary improvements.

Top Lube Pump Types for Efficient Fluid Transfer Solutions

| Pump Type | Application | Efficiency Rating | Key Features |

|---|---|---|---|

| Positive Displacement Pump | Industrial Lubrication | High | Consistent flow rate, Suitable for high viscosity fluids |

| Centrifugal Pump | Automotive Applications | Moderate | High flow rates, Lightweight design |

| Gear Pump | Hydraulic Systems | High | Durable, Excellent for low to medium viscosity fluids |

| Diaphragm Pump | Chemical Transfer | Moderate | Self-priming, Handles corrosive fluids |

| Peristaltic Pump | Food Industry | High | No contamination, Easy to clean |

Related Posts

-

Understanding the Mechanism of Lube Pumps: A Comprehensive Guide for Efficient Lubrication Systems

-

2025 Guide on Selecting the Best Lube Oil Pump: Performance & Efficiency Insights

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

Exploring the Surge of Rotary Positive Displacement Pumps: Insights from the 2025 China Import and Export Fair

-

How to Choose the Right Screw Pump for Your Industrial Needs