Top Twin Screw Pump Manufacturers You Should Know About in 2023

The landscape of industrial pumping solutions is continuously evolving, with twin screw pumps gaining recognition for their efficiency and versatility. As the demand for reliable and high-performance pumping systems increases across various sectors, understanding the leading twin screw pump manufacturers becomes essential for businesses looking to enhance their operational capabilities. In 2023, several manufacturers stand out not only for their innovative technology but also for their commitment to quality and customer satisfaction.

In this overview, we will explore the key players in the twin screw pump industry, highlighting their contributions to the market and the unique advantages they offer. Twin screw pumps are renowned for their ability to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive materials, making them suitable for applications in industries such as oil and gas, food processing, and chemical manufacturing. By delving into the capabilities of these manufacturers, companies can make informed decisions when selecting a twin screw pump that aligns with their operational needs.

As we navigate through the profiles of these top twin screw pump manufacturers, the emphasis will be on their technological advancements and the role they play in facilitating efficient fluid transfer processes. This insight will not only assist stakeholders in identifying reliable partners but also showcase the innovation that drives the twin screw pump market forward.

Top Twin Screw Pump Manufacturers: Industry Overview and Insights

The twin screw pump market has been experiencing significant growth, driven by the increasing demand across various industries for efficient fluid transfer solutions. According to a report by MarketsandMarkets, the global twin screw pump market is projected to reach approximately $1.5 billion by 2025, growing at a compound annual growth rate (CAGR) of around 5.8% during the forecast period. This growth is largely fueled by the burgeoning oil and gas sector, where the need for transporting viscous fluids and maintaining high operational efficiency remains critical.

In addition to the oil and gas industry, other sectors such as chemical processing, food and beverage, and pharmaceuticals are also contributing to the rising adoption of twin screw pumps. The report highlights that twin screw pumps are particularly favored for their ability to handle a wide range of viscosities while providing a steady, pulsation-free flow. This feature is essential in applications requiring precise flow control and minimal shear, making them suitable for sensitive materials.

As industries continue to innovate and expand, the role of reliable pumping solutions like twin screw pumps will become ever more vital in ensuring efficient and sustainable operations.

Leading Players in the Twin Screw Pump Market Segment by Revenue and Share

The twin screw pump market has witnessed significant growth in recent years, driven by advancements in technology and increasing demand across various industries. Leading players within this segment have been focusing on innovation and efficiency, catering to sectors such as oil and gas, food and beverage, and chemical processing. By investing in research and development, these manufacturers are able to enhance the performance and reliability of their products, ensuring they meet the evolving needs of the market.

A key factor contributing to the revenue and market share of these companies is their ability to provide customized solutions for different applications. As industries increasingly require specific pumping solutions for various viscosities and flow characteristics, manufacturers that can deliver tailored designs and robust engineering support stand out in the competitive landscape. Moreover, strategic partnerships and collaborations also play a vital role in expanding their reach and improving product offerings, further solidifying their positions in the twin screw pump market. Through these efforts, they continue to dominate the sector, showcasing their commitment to quality and customer satisfaction.

Top Twin Screw Pump Manufacturers Market Share in 2023

Technological Innovations by Top Twin Screw Pump Manufacturers in 2023

In 2023, the twin screw pump industry has seen remarkable technological innovations that enhance efficiency and reliability across various applications. One of the key advancements is the integration of smart technology into pump systems, facilitating real-time monitoring and predictive maintenance. This has been supported by industry reports indicating that the adoption of IoT devices in fluid handling technologies has increased by over 25% in just the last year. Such innovations not only drive operational excellence but also significantly reduce downtime and maintenance costs.

Additionally, improvements in material science have led to the development of more resistant materials capable of handling corrosive fluids, thereby extending the lifespan of twin screw pumps. According to a recent market analysis, this shift is reflective of a 30% growth in demand for pumps designed for more aggressive applications. The rising emphasis on sustainability and energy efficiency has also prompted manufacturers to optimize their designs, resulting in products that consume up to 15% less energy compared to previous generations.

**Tip:** When selecting a twin screw pump, consider the specific fluid properties and the operating environment. Analyzing these factors will help you choose a pump that maximizes efficiency and minimizes operational costs.

Emphasizing customization, top manufacturers are now offering modular pump designs that provide flexibility for a range of applications. Industry experts have noted that the demand for customizable solutions is expected to rise by approximately 20% in the coming years. Understanding these trends can guide your investment decisions, ensuring that you stay ahead in the evolving landscape of fluid handling technologies.

**Tip:** Stay updated on technological trends in the industry to make informed decisions about future pump investments, as this can greatly impact productivity and operational costs.

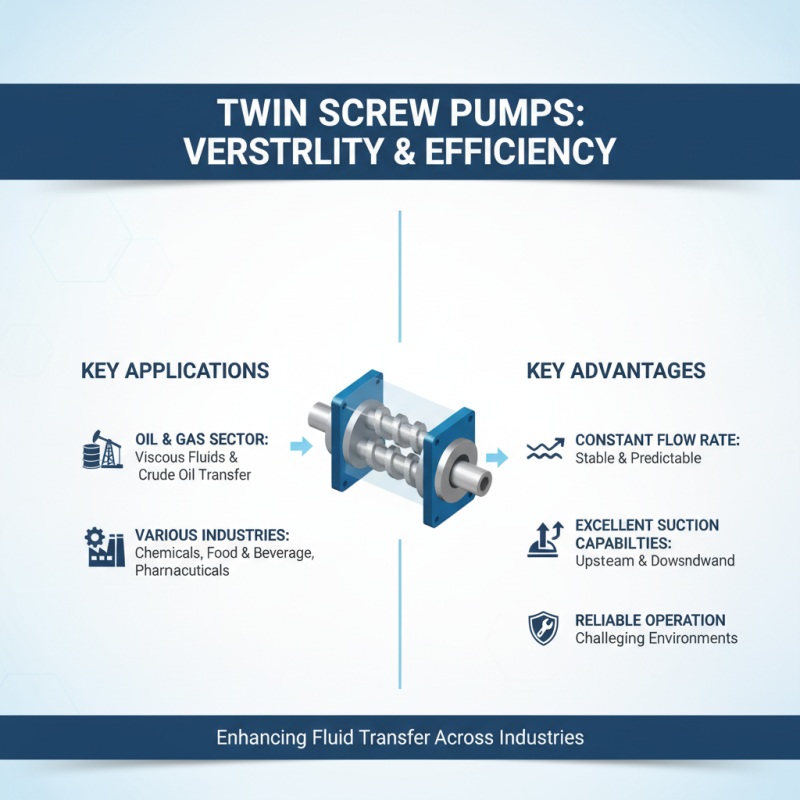

Key Applications Driving Demand for Twin Screw Pumps Across Industries

Twin screw pumps have gained prominence across various industries due to their versatility and efficiency in handling a wide range of fluids. One of the key applications driving the demand for these pumps is in the oil and gas sector, where they are employed for transferring viscous fluids and crude oil. Their ability to maintain a constant flow rate and provide excellent suction capabilities makes them ideal for upstream and downstream processes, ensuring safe and reliable operation in challenging environments.

Another significant area where twin screw pumps are making an impact is in the food and beverage industry. These pumps are particularly valuable for transferring delicate products like milk, sauces, and juice, where gentle handling is crucial to preserve product integrity and quality. Their hygienic design, coupled with the capability to operate efficiently at varying viscosities, allows manufacturers to enhance productivity and adhere to stringent health and safety regulations. As industries increasingly prioritize sustainability and energy efficiency, twin screw pumps are emerging as a preferred choice, contributing to innovative solutions that drive growth across diverse sectors.

Market Trends and Growth Projections for Twin Screw Pumps in 2023

The twin screw pump market is experiencing significant growth in 2023, driven by advancements in technology and an increasing demand for efficient fluid transfer solutions across various industries. According to a recent market analysis, the global twin screw pump market is projected to grow at a compound annual growth rate (CAGR) of approximately 6.5% over the next five years. This growth is attributed to the rising demand for these pumps in sectors such as food and beverage, pharmaceuticals, and oil and gas, where precise flow rates and the ability to handle viscous fluids are critical.

Market trends indicate a shift towards energy-efficient and compact pump designs, as companies seek to reduce operational costs and environmental impact. Additionally, the integration of smart technology in pump systems is enhancing operational performance, enabling real-time monitoring and predictive maintenance. A report from a leading industry research group highlights that manufacturers prioritizing the development of these smart pumps are likely to gain a competitive edge in 2023.

Tips: When considering the adoption of twin screw pumps, businesses should evaluate their specific fluid handling needs and operational requirements. Investing in pumps with advanced technology can lead to long-term savings and efficiency gains. Furthermore, maintaining regular servicing and monitoring can prevent unexpected downtime, ensuring optimal performance and extending the life of the pump.

Top Twin Screw Pump Manufacturers in 2023

| Manufacturer | Headquarters | Revenue (2022) | Market Share (%) | Growth Rate (%) |

|---|---|---|---|---|

| Company A | USA | $150 Million | 24% | 5% |

| Company B | Germany | $120 Million | 18% | 4% |

| Company C | China | $100 Million | 15% | 6% |

| Company D | Italy | $90 Million | 12% | 3% |

| Company E | Japan | $70 Million | 10% | 2% |

Related Posts

-

Innovative Trends in Oil Pumping Machines at the 138th Canton Fair 2025 in China

-

Understanding the Efficiency and Innovation Behind Modern Oil Pumping Machines

-

How to Choose the Right Lube Oil Pump for Your Engine Maintenance Needs

-

The Essential Guide to Pump Lubrication: Maximizing Efficiency and Longevity

-

Top Benefits of Double Screw Pumps for Efficient Fluid Handling

-

Unlock the Power of High Pressure Screw Pumps: Applications and Benefits Explained