10 Types of Industrial Pumps You Should Know About for Your Operations

When it comes to optimizing operations in various industries, understanding the different types of industrial pumps is essential. As John Smith, an eminent expert in fluid dynamics, once stated, “The choice of pump can significantly influence operational efficiency and cost-effectiveness.” With an array of pump types designed for specific applications, selecting the right one can enhance productivity and ensure the smooth functioning of machinery.

Industrial pumps vary from centrifugal to diaphragm designs, each serving distinct purposes in sectors ranging from manufacturing to wastewater management. As operations become increasingly complex, the need for tailored pumping solutions grows. Knowledge of the types of industrial pumps not only aids in efficient process design but also in troubleshooting existing systems. In this article, we will explore ten essential types of industrial pumps that you should know about, equipping you with the insights necessary to make informed decisions for your operations.

Types of Industrial Pumps: An Overview of Key Categories

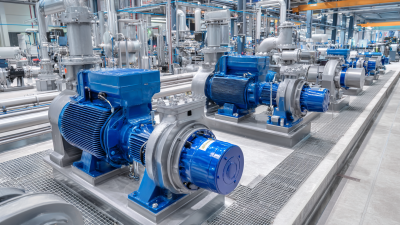

Industrial pumps play a crucial role in various manufacturing and processing operations, providing efficient fluid transfer for a wide range of applications. Understanding the different types of pumps available is key to optimizing operational efficiency. The main categories include centrifugal pumps, positive displacement pumps, submersible pumps, and diaphragm pumps, each serving specific industrial needs.

Centrifugal pumps, recognized for their high flow rates and ability to handle low-viscosity fluids, are widely used in water treatment and chemical processing. Positive displacement pumps, on the other hand, are ideal for moving high-viscosity fluids and can maintain a consistent flow rate regardless of pressure changes. According to the Global Industrial Pump Market report, the demand for these pumps is expected to grow significantly, driven by increasing industrial automation and the need for efficient fluid management systems.

**Tip**: When selecting a pump, consider the specific properties of the fluid you will be transferring, such as viscosity and temperature, as well as the required flow rate. For instance, choosing a submersible pump may be beneficial for applications that involve transferring liquids from deep wells or tanks, while diaphragm pumps are suitable for transferring corrosive or viscous materials.

Moreover, the recent shift towards environmentally friendly practices has led to the development of energy-efficient pump technologies. Investing in pumps with advanced features can not only reduce operational costs but also enhance your facility's sustainability efforts. **Tip**: Regular maintenance and timely replacement of seals and gaskets can extend the lifespan of your pumps, reducing downtime and maintenance costs in the long run.

10 Types of Industrial Pumps You Should Know About for Your Operations

| Pump Type | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Centrifugal Pump | Uses rotational energy to move liquids. | Water supply, chemical processing. | Efficient at high flow rates. | Not suitable for high-viscosity liquids. |

| Positive Displacement Pump | Moves liquid by trapping a fixed amount and forcing it through. | Oil and gas, food processing. | Can handle higher viscosities. | Potential for pulsation. |

| Diaphragm Pump | Uses a diaphragm to change the volume of the pumping chamber. | Chemical transfer, wastewater treatment. | Can handle corrosive liquids. | Limited flow rates. |

| Submersible Pump | Operates underwater to pump fluids. | Dewatering, sewage systems. | Highly effective in removing water. | Requires waterproofing and additional parts. |

| Peristaltic Pump | Uses rollers to compress a hose and create flow. | Chemical dosing, food and beverage. | Minimal contamination risk. | Not suitable for high-pressure applications. |

| Gear Pump | Uses gears to pump fluids by moving them between rotating surfaces. | Hydraulic systems, oil transfer. | Can maintain a constant flow rate. | More complex and costly to maintain. |

| Screw Pump | Uses one or more screws to move fluid. | Viscous fluids, slurries. | Handles thicker fluids efficiently. | Can be expensive to install. |

| Vacuum Pump | Removes gas from a sealed volume to create a vacuum. | Packaging, vacuum distillation. | Essential in various industrial processes. | Requires maintenance to prevent leaks. |

| Lobe Pump | Utilizes rotating lobes to move liquid. | Food production, pharmaceutical. | Gentle handling of products. | More complex design can affect maintenance. |

Centrifugal Pumps: Principles and Applications in Industries

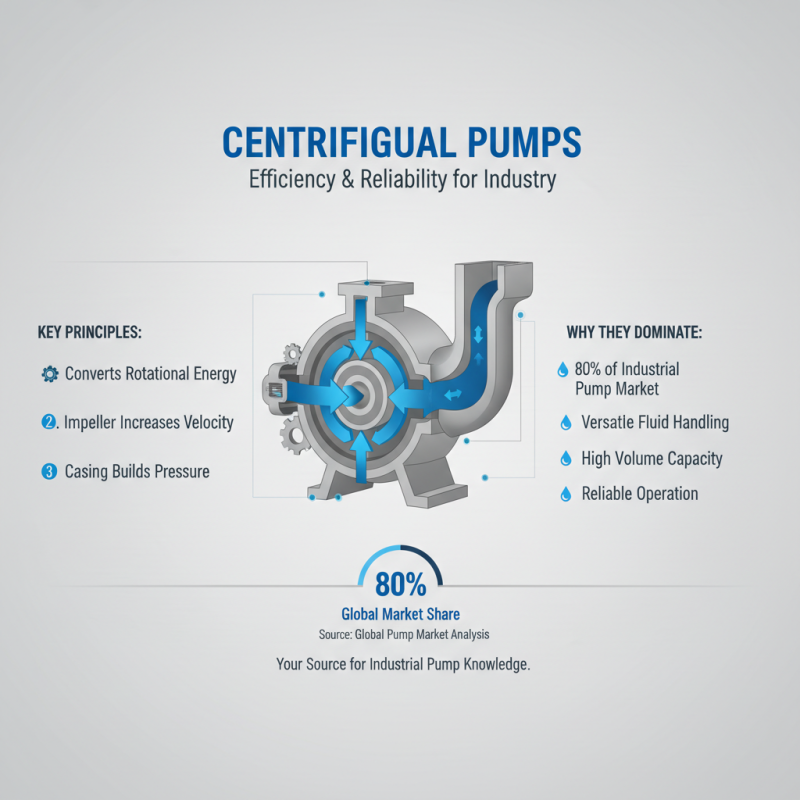

Centrifugal pumps are widely recognized for their efficiency and reliability in various industrial applications. Operating on the principle of converting rotational kinetic energy into hydrodynamic energy, these pumps utilize a rotating impeller to increase the velocity of the fluid, which is then converted into pressure as it flows through the pump casing. According to a report by the Global Pump Market Analysis, centrifugal pumps account for approximately 80% of the total industrial pump market due to their versatility and ability to handle large volumes of fluids with relative ease.

In industries such as water treatment, chemical processing, and oil and gas, centrifugal pumps are favored for their simple design and low maintenance requirements. A study published by the International Journal of Engineering Research reveals that these pumps can achieve efficiency levels exceeding 90% in optimal conditions, making them an economical choice for continuous operation. Furthermore, advancements in pump technology have led to innovations such as variable frequency drives, which optimize flow rates and further enhance energy savings. As industries continue to evolve, the demand for efficient and robust pumping solutions like centrifugal pumps is expected to grow, reinforcing their significance in modern operations.

Positive Displacement Pumps: Mechanisms and Use Cases

Positive displacement pumps are pivotal in various industrial applications due to their ability to transport fluids with high efficiency and precision. These pumps operate by trapping a fixed volume of fluid and then forcing it through the discharge pipe, making them ideal for handling thick, viscous liquids or fluids containing solids. Various mechanisms exist within positive displacement pumps, including gear, diaphragm, and rotary screw designs, each suited for specific operational requirements.

One of the primary use cases for positive displacement pumps is in the oil and gas industry, where they are utilized to move crude oil from extraction sites to processing facilities. Their capacity to manage high pressures makes them a reliable choice for such demanding environments. Additionally, they are commonly found in food processing and chemical industries, where they ensure that products are transported without shear or degradation, maintaining the quality and integrity of the fluids processed. The versatility of positive displacement pumps extends to applications involving hydraulic systems, water treatment, and even pharmaceuticals, where precise dosing and flow control are critical.

Understanding Positive Displacement Pumps: Mechanisms and Use Cases

Diaphragm Pumps: Features and Operational Benefits

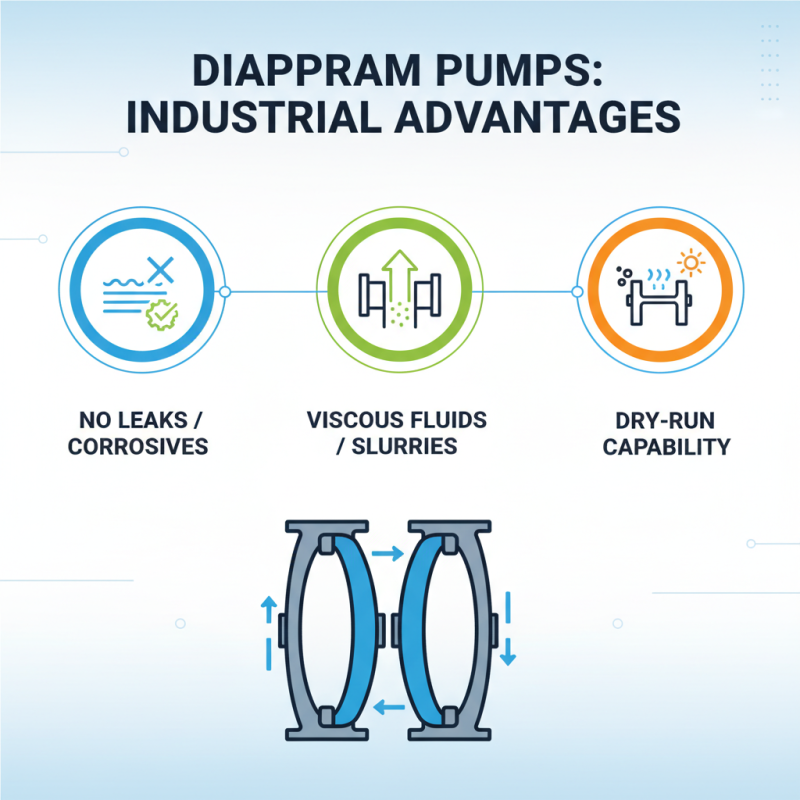

Diaphragm pumps are a vital component in various industrial applications due to their unique operational features and benefits. These pumps utilize a flexible diaphragm to create a pumping action, which efficiently moves liquids and slurries without the need for mechanical seals. This design minimizes the risk of leaks, making diaphragm pumps particularly suitable for handling corrosive and viscous fluids. Furthermore, their ability to run dry without damage adds to their versatility, enabling them to operate in challenging environments where other pumps might fail.

Another significant advantage of diaphragm pumps is their ease of maintenance and operational efficiency. Many models feature a simple design that allows for quick disassembly, facilitating routine inspections and repairs without extensive downtime. Additionally, the ability to adjust flow rates easily makes them ideal for processes requiring precise control. Their self-priming capability also enhances operational flexibility, allowing these pumps to pull liquids from underground tanks or pits without additional equipment. Overall, diaphragm pumps stand out for their reliability and adaptability, making them an excellent choice for various industrial operations.

Peristaltic Pumps: Advantages in Fluid Handling Processes

Peristaltic pumps are a unique type of positive displacement pump widely utilized in various industrial applications, particularly noted for their effectiveness in fluid handling processes. Unlike conventional pumps, peristaltic pumps operate through a simple mechanism in which a rotating roller compresses a flexible tube, creating a vacuum that draws fluid into the pump. This action allows for precise control over flow rates, making them particularly advantageous in processes requiring accuracy, such as in pharmaceuticals and food production.

One of the key advantages of peristaltic pumps is their ability to handle shear-sensitive fluids without causing damage or altering their properties. This makes them ideal for transferring delicate materials like biological samples or viscous substances. Additionally, as the fluid only contacts the interior of the tubing, peristaltic pumps exhibit lower risk of contamination, enhancing hygienic standards in critical applications. Their simple design also allows for easy maintenance and replacement of tubing, making them cost-effective over time. As industries increasingly prioritize efficiency and safety in fluid handling, peristaltic pumps stand out as a reliable choice.

Related Posts

-

How to Choose the Right Type of Industrial Pump for Your Application

-

Exploring the Different Types of Positive Displacement Pumps for Optimized Fluid Transfer

-

Unlock the Power of High Pressure Screw Pumps: Applications and Benefits Explained

-

Top Benefits of Positive Displacement Water Pumps and Their Uses

-

How to Maximize Efficiency with Screw Pumps in Industrial Applications

-

Why You Should Choose Air Oil Pumps for Your Industrial Needs Today